NOVATIO MAP0002000-E User manual

900W DEFENDER

MAP0002000-E

QUICK START GUIDE

TROUBLESHOOTING

CONTACT INFO

266 Calvary Street

Waltham MA 02453

www.novatioengineering.com

SYSTEM SPECIFICATIONS

Platform Technology

Honda

EU!000i

Dry Weight

33Pounds

System Dimensions L x W x H

17.8”

x 11.5” x 14.9”

AC Output

120V

0-900 W continuous sea level

120V

0-750W W continuous above 4000 ft, 104°F

120V

1000W Peak

Operating Range

0°F - 125°F

Fuel Tank

0.6 gallons

Fuel(s)

JP

-8, F24, JET A, JP-5 (gasoline andnDF2 can be

used in select models.

Run Time on JP

-8 @ 1250 W AC

5.2

hours

BEFORE OPERATION

Check Oil –A low oil level will cause the Oil Alert system to shut down the engine.

Check Air Filter –A dirty air filter will restrict air flow to the engine, reducing engine

and generator performance.

Check Fuel Level –Starting with a full tank will help to eliminate or reduce operating

interruptions for refueling.

Check that any appliances are turned off or disconnected from generator. The

generator may be hard to start if a load is connected.

Prior to starting engine, inspect the following every time:

Refer to manual for detailed instructions.

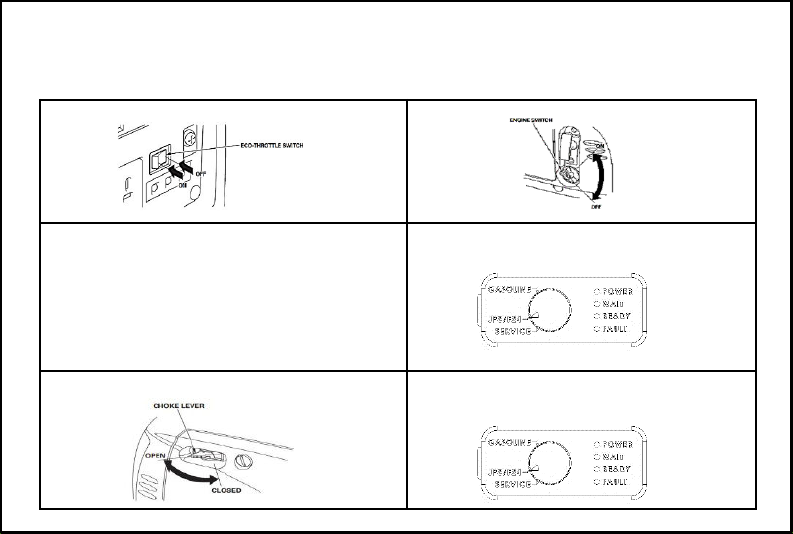

1. Turn FUEL TANK CAP VENT LEVER to ‘ON’ position. 4. Turn ENGINE SWITCH to ‘ON ’ position.

2. Turn ECO-THROTTLE SWITCH to ‘OFF’ position.

5. Ensure fuel selector switch is set to appropriate fuel.

3. Make sure CHOKE LEVER is in ‘open’ position to start.

6. Begin pulling the STARTER GRIP once the ‘READY’ indicator

(green) has lit up. Engine should start in 1-3 pulls. If engine does

not start, see troubleshooting guide. DO NOT PULL MORE THAN 25

TIMES.

STARTING ENGINE

1. If engine does not speed up after several seconds , briefly turn

CHOKE LEVER to ‘CLOSED’ position.

.

3. Choke can typically be opened and some load applied at less than 1

minute after start-up, slightly longer if ambient temperatures are cold. If

opened or too large a load applied too early, engine operation can

become unsteady. Yellow light on User Interface indicates system

"warm-up" mode during start-up. When yellow light is no longer

illuminated, engine is fully warmed up and full load can be applied.

2. Allow engine to warm up for 20 seconds to 1 minute then turn

the CHOKE LEVER to the ‘OPEN’ position.

STARTING ENGINE (cont’d)

STARTING ENGINE (USING E-start)

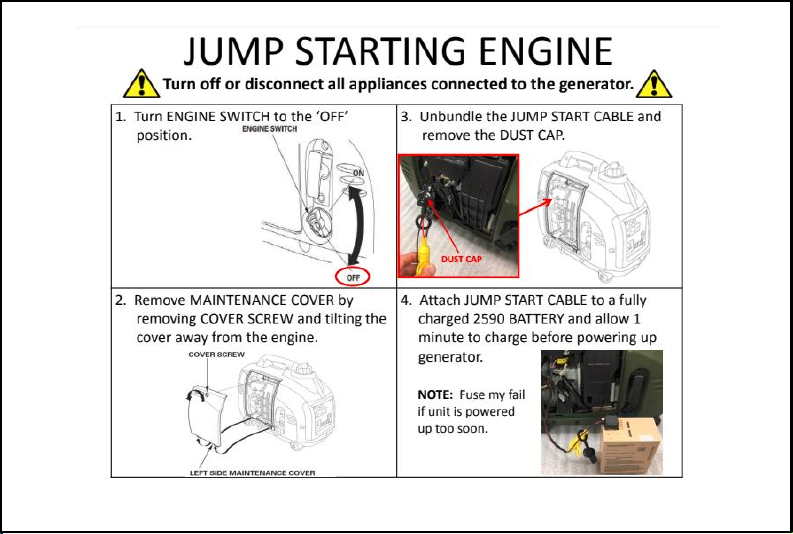

1. Plug Amphenol connector into front of generator. 4. Turn ENGINE SWITCH to ‘ON ’ position.

2. Turn FUEL TANK CAP VENT LEVER to ‘ON’ position.

5. Ensure fuel selector switch is set to appropriate fuel.

3. Make sure CHOKE LEVER is in ‘OPEN’ position to start.

6. Press power button to start generator

STOPPING ENGINE

1. Turn ENGINE SWITCH to the ‘OFF’ position.

2. Allow engine to cool, turn FUEL TANK

CAP VENT to ‘OFF’ position.

Turn off or disconnect all appliances connected to the generator.

AC OPERATION

1. Ensure that OUTPUT INDICATOR is illuminated.

2. Plug appliance into the receptacle.

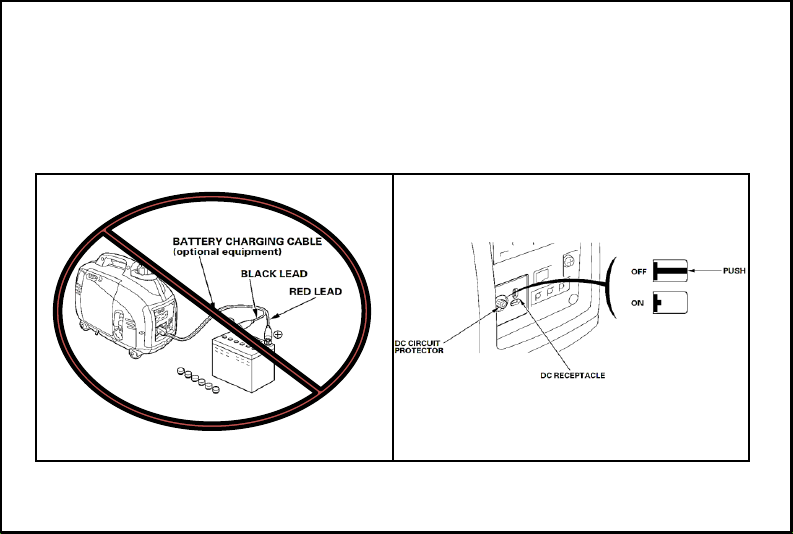

DC OPERATION

The NEI-1001-H-E has not been approved for charging external batteries, so caution must be

used with generator DC output.

Please contact Novatio for support if DC power is required.

MAINTENANCE & SERVICE

Unless otherwise noted, maintenance procedures should be performed

regularly according to the maintenance schedule. For complete maintenance

schedule, review full user manual.

The maintenance schedule applies to normal operating conditions. If

generator is operated under unusual conditions, such as sustained high-load, or high-

temperature or low-temperature operation, or operated in dusty conditions, consult

the full user manual for maintenance directions. Otherwise, consult Novatio

Engineering for recommendations applicable to your individual needs and use.

ALL MAINTENANCE SHOULD BE PERFORMED WITH THE ENGINE TURNED OFF.

Service Items detailed below

•Engine Oil

•Electrical Connectors

•Measuring and External Charging of Battery Pack

•Clearing Fuel Lines

ENGINE OIL

Engine oil should be changed according to the schedule below under normal operating

conditions. If generator is operated under unusual conditions, refer to complete manual.

Otherwise, consult Novatio Engineering .

[1] If operating generator in temperatures below 20°F, or if average load is less than 500W, change oil every 25 hours. If engine exhaust is carrying

excessive white smoke, change oil.

[2] Service more frequently when used in dusty areas.

[3] These items should be serviced by a qualified mechanic, unless you have the proper tools and are mechanically proficient.

[4] For commercial use, log hours of operation to determine proper maintenance intervals.

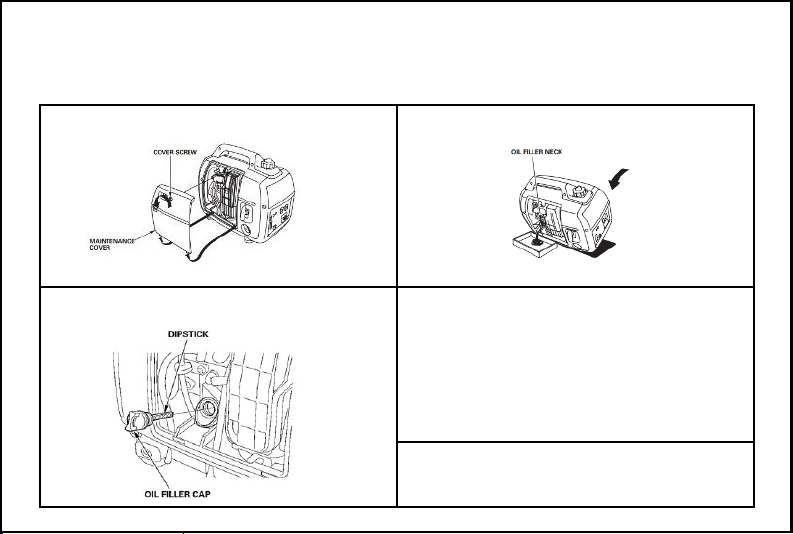

ENGINE OIL CHANGE

1. Open MAINTENANCE COVER carefully, tilting cover away from

engine.

3. With a suitable container in place, pour the oil by tipping the

engine toward the OIL FILLER NECK.

2. Tilt engine away from user (away from OIL FILLER NECK) to avoid

spilling oil, and unscrew the OIL FILLER CAP.

4. With engine in level position, fill to the bottom of the first threads

the oil filler neck (350ml) with the recommended oil .

5. Reinstall the OIL FILLER CAP and the MAINTENANCE COVER

securely.

1. Engine will not start

or will not remain running

Possible cause

Troubleshooting action

Low fuel levels Add fuel to fuel tank

Selector switch in wrong position Confirm selector switch in appropriate position

Air in fuel line Drain fuel through drain port until air bubbles are all pushed out.

Excessive fuel in cylinder Turn SWITCH to ‘SERVICE’ position and try starting engine. After a few pulls, or after engine

starts up and then stops, turn SWITCH to ‘RUN’ position in for appropriate fuel and re-start.

Oil alert system Ensure correct oil levels

Low batteries If LEDs on UI board do not illuminate, re-

charge the batteries according to the instructions in

the “JUMP START” section of this guide.

Weak/no spark Remove and dry off spark plug

Other Contact Novatio Engineering, Inc.

2. Engine operating but not producing AC power

GFCI disconnected Reset GFCI

Overload Reduce load (if load is already below 1250W, contact Novatio Engineering)

Other See troubleshooting for “rough operation and unsteady AC voltage”

TROUBLESHOOTING

TROUBLESHOOTING (cont.)

3. Rough operation or

visibly dirty exhaust

Possible cause

Troubleshooting action

Choke in closed position Make sure choke is in open position (lever pointed to the left) after engine has warmed up

High oil levels or diluted oil Change oil and fill to recommended levels

Lack of fuel due to fuel cap vent “off” Turn FUEL CAP VENT LEVER to ‘ON’ position

Wrong fuel Make sure system is being run with the type of fuel selected.

Engine in “Eco-mode” Set ECO-MODE SWITCH to ‘OFF’

Other Contact Novatio Engineering

4. Unsteady AC voltage or engine shuts

down

Low fuel levels Add fuel to fuel tank

Overload Reduce load (if load is already below 1250W, contact Novatio Engineering)

Engine in “Eco-mode”

Set ECO-MODE SWITCH to ‘OFF’

Table of contents

Popular Portable Generator manuals by other brands

Haas

Haas Vector Drive 20HP troubleshooting guide

Champion

Champion 41535 Owner's manual & operating instructions

Rohde & Schwarz

Rohde & Schwarz AM 300 operating manual

Highland

Highland T560 Technical manual

Generac Power Systems

Generac Power Systems 005724-0 owner's manual

Sole Diesel

Sole Diesel 14 GSC Operator's manual