Sole Diesel 14 GSC User manual

U_ GBAV_EN, U_GBMV_EN, U_ GBBA_EN, U_GBNA_EN, U_ GCAS_EN, U_GCMS_EN,

U_ GCAW_EN, U_GCMW_EN, U_ GDAT_EN, U_GDMT_EN, U_ GDAX_EN, U_GDMX_EN

Rev. 3

1

Rev. 3

2

Introduction

Presentation

Dear Customer,

First of all, we would like to thank you for choosing a Solé Diesel product. We recommend that

you read this manual carefully before carrying out any of the operations and keep it close at hand, near

the genset, as it can be of great use in the future.

Our goal as a manufacturing company is that you enjoy our product, regardless of the use you

make of it. The equipment manufactured in Solé Diesel facilities is designed to offer the highest

performance in the most demanding operating conditions.

NOTICE

The images, text and information contained in this manual are based on the product’s features at the time

of publication. Solé Diesel reserves the right to modify this document without prior notice.

Abbreviations

BTDC: Before Top Dead Center

ATDC: After Top Dead Center

BBDC: Before Bottom Dead Center

ABDC: After Bottom Dead Center

API: American Petroleum Institute

ACEA: European Automobile Manufacturers’ Association

ASTM: American Society for Testing Materials

TBD: To Be Determined

Units of measurement

Measurements are based on the International System of Units (SI), and their converted metric

values are indicated in parentheses (). For metric conversion, the following rates are used:

-Pressure: 1 Pa = 1,0197 · 10-5 kgf/cm2= 1 · 10-5 bar

-Torque: 1 Nm = 0,10197 kgf·m

-Force: 1 N = 0,10197 kgf

-Power: 1 W = 1,341 · 10-3 HP

3

Rev. 3

TABLE OF CONTENTS

Introduction 2

Safety Precautions and Instructions 7

Service Assistance 11

Section 1 Genset Information 12

1.1 Genset Identification 12

1.2 Technical Specifications 13

1.3 Genset Limited Warranty 17

Restrictions 17

After-sales Service Contact 18

Section 2 Transport, Handling and Storage 19

2.1 Receipt 19

2.2 Transporting and Handling the Packed Genset 19

2.3 Transporting and Handling the Unpacked Genset 20

2.4 Storage of Packed and Unpacked Genset 21

Section 3 Installation 22

3.1 Angular Operation 22

3.2 Genset Installation 22

3.3 Prestart Checklist 23

Section 4 Operation 24

4.1 Starting Genset 24

4.2 Stopping Genset 24

4.3 Genset Operation at Low Temperatures 25

4.4 Winterization and Preservation 25

4.5 Restoration of Operational conditions 26

Section 5 Systems and Scheduled Maintenance 27

5.1 Operating Description 27

5.2 Periodic Maintenance Schedule 30

5.3 General 32

Maintenance Task. Screw tightening, fastening 32

Maintenance Task. Valve clearance Inspection 32

Maintenance Task. Compression pressure Inspection 33

5.4 Lubrication System 34

Circuit Description 34

Oil Specifications 35

Maintenance Task. Oil level Check 35

Maintenance Task. Oil Fill / Change 36

Maintenance Task. Oil filter Change 37

5.5 Fuel System 37

Circuit Description 37

Fuel Specifications 37

Maintenance Task. Fuel level Inspection 38

Maintenance Task. Fuel tank Clean 38

Maintenance Task. Fuel filter Change 38

Maintenance Task. Water separator filter Purgue 38

Maintenance Task. Injection pump Inspection 38

Maintenance Task. Injector Inspection 39

Maintenance Task. Bleeding air from the fuel system 40

4

5.6 Cooling System 41

Coolant circuit Description 41

Seawater circuit Description 41

Coolant Specifications 41

Maintenance Task. Coolant Check 42

Maintenance Task. Coolant Fill / Change 42

Maintenance Task. Seawater filter Inspection 43

Maintenance Task. Seawater pump impeller Inspection 43

5.7 Inlet and Exhaust System 44

Exhaust circuit Description 44

Maintenance Task. Air filter Inspection 45

Maintenance Task. Exhaust gas, noise and vibrations Inspection 45

5.8 Electrical System 46

SCO 10 Panel 46

Battery 47

Circuit Protection 47

Maintenance Task. Incandescent glow plug Inspection 47

Maintenance Task. Starter motor Inspection 48

Maintenance Task. Alternator belt tension Inspection 48

Maintenance Task. Battery Level 49

5.9 Alternator 49

Maintenance Task. Control of windings and electrical Insulation 49

Maintenance Task. Control of bearings 49

Maintenance Task. Cleaning and Lubrication 50

Section 6 Troubleshooting 50

Section 7 Technical Annexes

7.1 SCO 10 Generator Control Panel. Operator’s Manual

7.2 Genset Dimensions

7.3 Alternator’s Connections

7.4 Regulator’s Connections

7.5 Electrical Wiring Drawings

7 GSC / 8 GSAC / 10 GSC / 12 GSAC / 14 GSC / 17 GSAC

Earth Isolated 7 GSC / 8 GSAC / 10 GSC / 12 GSAC / 14 GSC / 17 GSAC

8 GTC / 10 GTAC / 11 GTC / 14 GTAC / 17 GTC / 20 GTAC

Earth Isolated 8 GTC / 10 GTAC / 11 GTC / 14 GTAC / 17 GTC / 20 GTAC

7.6 Tightening Torques

7.7 Instructions for Decommissioning, Scrapping and Disposal

5

Rev. 3

TABLE OF FIGURES

Fig. 1. Warning label. In case of fire 7

Fig. 2. Warning label. General precautions 8

Fig. 3. Warning label. Rotating parts 8

Fig. 4. Warning. Carbon monoxide 9

Fig. 5. Warning. Battery charging 9

Fig. 6. Warning. Hot engine 9

Fig. 7. Caution label. Overcrank consequences 9

Fig. 8. Caution label. Not a step 10

Fig. 9. Nameplate location 12

Fig. 10. Genset nameplate 12

Fig. 11. Packed genset 19

Fig. 12. 8 GTC / 10 GTAC / 7 GSC / 8 GSAC lifting eyebolts 20

Fig. 13. 11 GTC / 14 GTAC / 10 GSC / 12 GSAC / 17 GTC / 20 GTAC / 14 GSC / 17 GSAC lifting

eyebolts 20

Fig. 14. Genset controller 24

Fig. 15. Genset covers 27

Fig. 16. Location of genset elements 8 GTC / 10 GTAC / 7 GSC / 8 GSAC 28

Fig. 17. Location of genset elements 11 GTC / 14 GTAC / 10 GSC / 12 GSAC / 17 GTC / 20 GTAC /

14 GSC / 17 GSAC 29

Fig. 18. Maintenance kit 32

Fig. 19. Valve clearance inspection 33

Fig. 20. Valve clearance adjust 33

Fig. 21. Compression pressure inspection 33

Fig. 22. Lubrication circuit 34

Fig. 24. Solé Diesel oil SAE 15W40 35

Fig. 25. Modification of oil dipstick for inclined operation 36

Fig. 26. Oil filter change 37

Fig. 27. Fuel circuit 37

Fig. 28. Fuel filter change 38

Fig. 29. Water separator filter change 38

Fig. 29. Remove injector 39

Fig. 31. Test injection pressure 39

Fig. 32. Adjust injection pressure 39

Fig. 33. Shape of injector discharge 39

Fig. 34. Tip and nozzle of injector 40

Fig. 36. Coolant circuit 41

Fig. 37. Seawater circuit 41

Fig. 38. Coolant drain plugs 42

Fig. 39. Refill coolant circuit 42

Fig. 40. Seawater filter 43

Fig. 41. Seawater pump impeller inspection 43

Fig. 43. Installation type 1 when between water injection point of wet exhaust and waterline is

minimum 150 mm 44

Fig. 44. Installation type 2 when between water injection point of wet exhaust and waterline

there is less than 150 mm or the point of injection is below waterline 45

Fig. 45. Air filter inspection 45

Fig. 46. Genset panel 46

Fig. 47. Incandescent glow plug inspection 47

Fig. 48. Glow plug behavior 48

Fig. 49. Starter motor inspection 48

Fig. 50. Alternator belt tension inspection 48

6

LIST OF TABLES

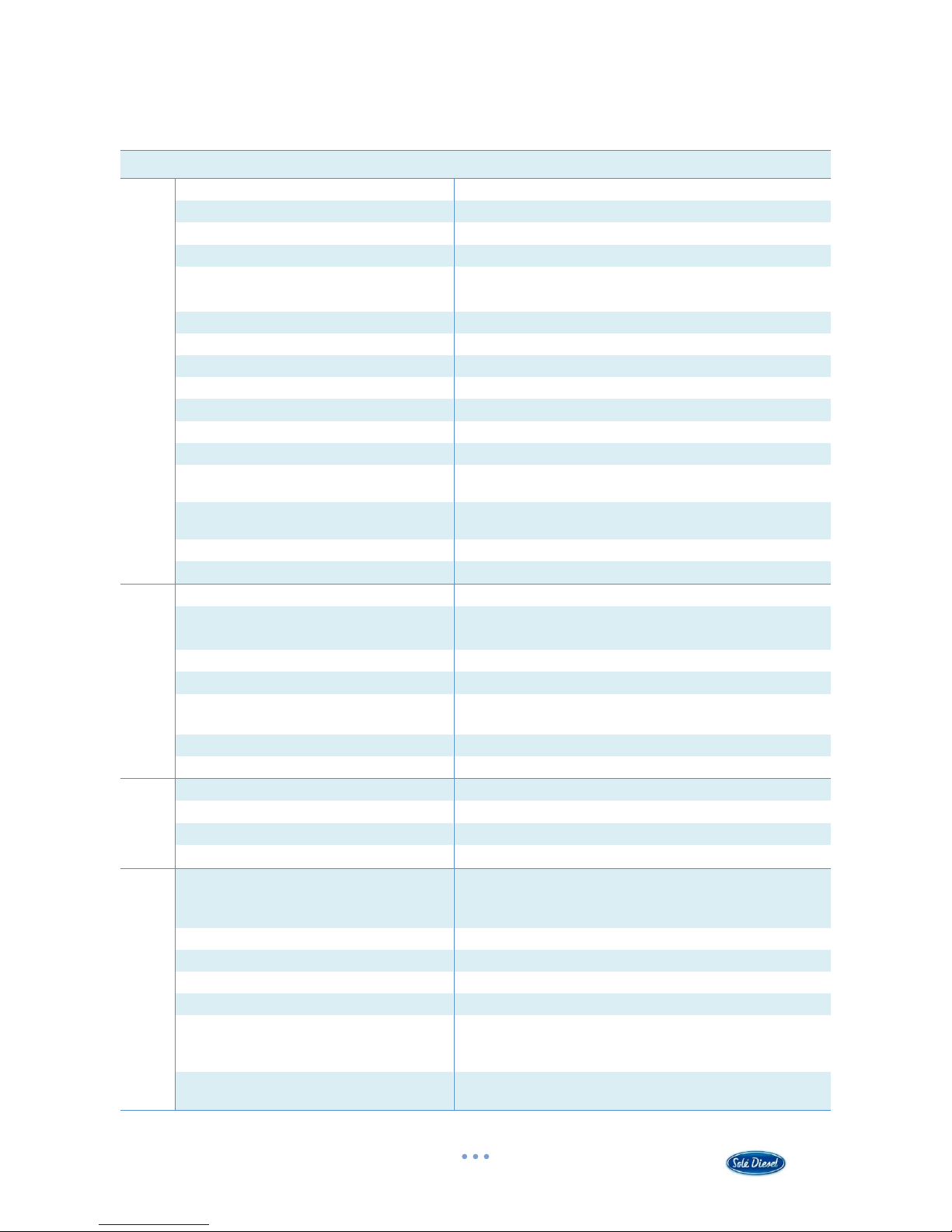

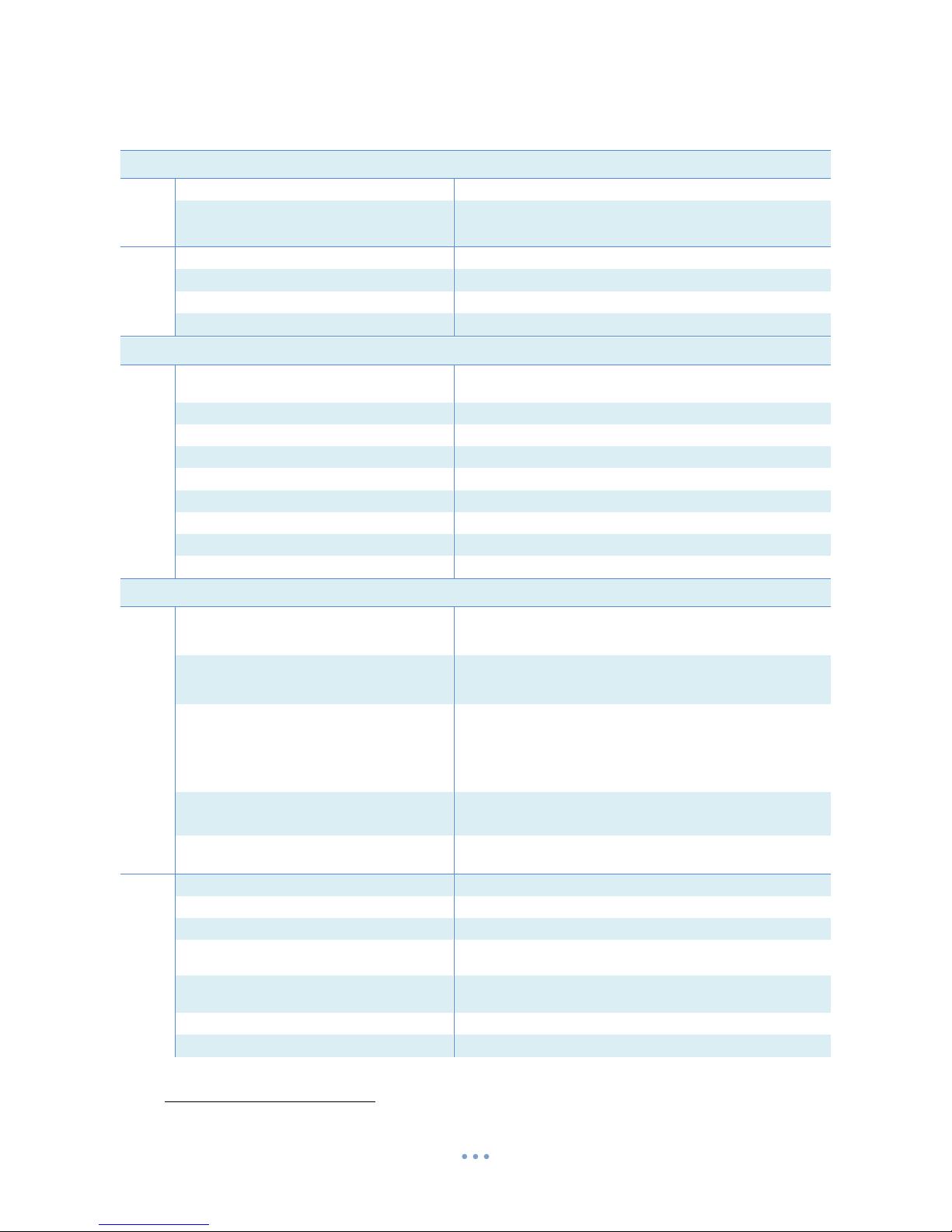

Table 1. Technical Specifications 8 GTC / 10 GTAC / 7 GSC / 8 GSAC / 11 GTC / 14 GTAC 14

Table 2. Technical Specifications 10 GSC / 12 GSAC / 17 GTC / 20 GTAC / 14 GSC / 17 GSAC 16

Table 3. Limited warranty coverage periods 17

Table 4. Angular Operation 22

Table 5. Periodic maintenance schedule 31

Table 6. Valve clearance 32

Table 7. Injection sequence 32

Table 8. Compression pressure inspection 34

Table 9. Oil circuit capacity 35

Table 10. Modification of oil dipstick for inclined operation 8 GTC / 10 GTAC / 7 GSC / 8 GSAC 35

Table 11. Modification of oil dipstick for inclined operation 36

Table 12. Injection pressure 39

Table 13. Coolant circuit capacity 41

Table 14. Minimum exhaust muffler capacity 44

Table 15. References of genset controller 46

Table 17. Recommended battery capacity 47

Table 17. AC Breaker 47

Table 18. Alternator belt tension inspection 48

Table 19. Operating hours to alternator bearing replace 49

Table 20. Toubleshooting 55

7

Rev. 3

Safety Precautions and Instructions

Solé Diesel is concerned for your safety and your machine’s condition. Safety Precautions and

Instructions are one of the primary ways to call your attention to the potential hazards associated with

our genset operation. Follow the precautions listed throughout the manual before and during operation

and maintenance procedures for your safety, the safety of others and the performance of your genset.

Types of Safety Precautions:

-WARNING:indicates the presence of a hazard that can cause severe personal injury,

death or substantial property damage.

-CAUTION: indicates the presence of a hazard that will or can cause minor personal injury

or property damage.

-NOTICE: communicates installation, operation and maintenance information that is safety

related but not hazard related.

WARNING

Servicing the fuel system and

combustible materials. A flash fire

can cause severe injury or death.

Do not smoke or permit flames or

sparks near the fuel injection system,

fuel line, fuel filter, fuel pump, or

other potential sources of spilled fuels

or fuel vapors.

Fig. 1. Warning label. In case of fire

Never add fuel to the tank while the engine is running because spilled fuel may ignite on contact with

hot parts or from sparks. Catch fuels in an approved container when removing the fuel line or fuel

system. Keep the fuel lines and connections tight and in good condition. Do not replace flexible fuel lines

with rigid lines and use flexible sections to avoid fuel line breakage caused by vibrations.

Keep the compartment and the genset clean and free of debris to minimize the risk of fire.

Servicing the air cleaner. A sudden backfire can cause severe injury or death.

Do not operate the genset with the air cleaner/silencer removed.

Combustible materials. A fire can cause severe injury or death.

Genset fuels, fuel vapors and combustible materials are flammable and explosive. Handle these

materials carefully to minimize the risk of fire or explosion. Equip the compartment or nearby area with

a fully charged fire extinguisher.

8

In case of fire do not open sound shield compartment and follow these instructions:

1. Shut down genset(s)

2. Continuously discharge entire contents of a halon or CO2portable fire extinguisher (or other

provision) immediately.

There are some aspects that you must

consider:

Obligations:

Operator Manual of genset. Read and

understand it before operating and

servicing the genset to ensure that you

follow safe operating practices and

maintenance procedures.

Grounding electrical equipment. Connect

genset to earth connection.

Hearing protection. Use it to avoid

hearing loss when you operate the

genset.

Fig. 2. Warning label. General precautions

Prohibitions:

Restricted Access. Only authorized personnel can access to genset space.

Do not burn garbage. It is necessary to offload the genset waste in a special place.

Do not smoke or permit flames or sparks to occur near sources of spilled fuel or fuel vapors.

Dangers:

Hazardous voltage. Operate the genset only when all guards and electrical enclosures are in place.

Before working on the genset disconnect it from the load by switching off the line circuit breaker.

Hot parts, coolant and steam. Stop the genset and allow it to cool before touching or removing any

genset part.

Moving parts. Keep hands, feet, hair, clothing and test leads away from the belts and pulleys when the

genset is running. Replace guards, screens and covers before operating the genset.

Before working on the genset or connected equipment, disable

the genset as follows:

(1) Set the genset controller (SCO 10) to OFF Mode.

(2) Disconnect the power input from battery.

(3) Disconnect the battery cables. Remove the negative (-)

lead first when disconnecting the battery. Reconnect the

negative (-) lead last when reconnecting the battery.

Follow these precautions to prevent the starting of the genset

by genset controller (SCO 10), remote start/stop switch, or

engine start command from a remote computer.

Fig. 3. Warning label. Rotating parts

9

Rev. 3

Other WARNINGS (no adhesive label):

Carbon monoxide (CO) can cause severe nausea, fainting or death.

Genset exhaust contains carbon monoxide gas. Carbon monoxide is an odorless, colorless, tasteless,

nonirritating gas that can cause death if inhaled for even a short time.

Get fresh air and do not sit, lie down or fall asleep if anyone shows signs of

carbon monoxide poisoning:

-Light-headedness, dizziness

-Physical fatigue, weakness in joints and muscles

-Sleepiness, mental fatigue, inability to concentrate or speak

clearly, blurred vision

-Stomachache, vomiting, nausea

Fig. 4. Warning. Carbon monoxide

Keep the area around the battery well ventilated. While the engine is running

or the battery is charging, hydrogen gas is produced which can be easily ignited.

Never allow battery fluid (battery contains sulfuric acid) to come in contact

with clothing, skin or eyes. Always wear safety gloves and protective clothing

when servicing the battery. If battery fluid contacts the eyes and/or skin,

immediately flush the affected area with a large amount of clean water and

obtain prompt medical treatment.

Fig. 5. Warning. Battery charging

Never remove the cooler cap if the engine is hot. Steam and hot engine coolant

will spurt out and seriously burn you. Allow the engine to cool down before you

attempt to remove the cooler cap.

Fig. 6. Warning. Hot engine

CAUTION

If the genset does not start after 3 crank attempts an overcrank fault occurs:

1) Close the seacock

2) Drain the water from the exhaust system at the

waterlock completely

3) Do not try to restart genset until the cause of

start fail is identified

Fig. 7. Caution label. Overcrank consequences

10

Do not use the cabin of the genset as a

step.

Using it as a step can cause the cabin

damage and, moreover, standing on the

genset could impair its operation.

Fig. 8. Caution label. Not a step

NOTICE

1. The installer / operator of the genset has to wear suitable CLOTHING for the workplace and the

situation; in particular, avoid loose clothes, chains, bracelets, rings and all accessories that

could become entangled with moving parts.

2. The installer / operator of the genset has to wear personal protective equipment such as

gloves, work shoes, eye and hearing protection as required by the task.

3. The area in which the operator is working has to be kept tidy and free of oil and other liquid

spillages and solid waste (metal chips, etc.).

11

Rev. 3

Service Assistance

For an updated list of our international distribution network, visit Dealers section in our web

page www.solediesel.com.

Or request this information by contacting Solé Diesel at:

e-mail: [email protected]

Phone: +34 93 775 14 00

12

Section 1 Genset Information

1.1 Genset Identification

MANUFACTURER:

SOLÉ, S.A.

Road from Martorell to Gelida, km 2

08760 MARTORELL

(BARCELONA) SPAIN

GENSET MODEL:

7 GSC / 8 GTC / 10 GSC / 11 GTC /

14 GSC / 17 GTC (1500 rpm)

8 GSAC / 10 GTAC / 12 GSAC / 14 GTAC /

17 GSAC / 20 GTAC (1800 rpm)

Fig. 9. Nameplate location

Fig. 10. Genset nameplate

The standard genset can run at ambient temperatures between -18ºC and +45ºC.

13

Rev. 3

1.2 Technical Specifications

8 GTC

7 GSC

11 GTC

10 GTAC

8 GSAC

14 GTAC

DIESEL ENGINE

General Information

Type

Water-cooled, Diesel 4-stroke cycle

Direction of rotation

Anti-clockwise observing genset from flywheel side

No. of cylinders - arrangement

3 - in line

Allowable Exhaust Back Pressure (kPa)

Max. 6,57

Timing

Pushrod and rocker arm with gear driven camshaft in

crankcase

Bore (mm)

76

76

78

Stroke (mm)

70

70

92

Total displacement (c.c.)

952

952

1318

Compression ratio

23:1

23:1

22:1

Ignition sequence

1-3-2

Fuel injection timing

BTDC 15º

BTDC 15º

BTDC 17º

Injection pressure (kPa)

13,73 (140 kg/cm2)

Inlet and exhaust valve clearance - cold

genset (mm)

0,25

RPM (rpm)

1500 (8 GTC)

1800 (10 GTAC)

1500 (7 GSC)

1800 (8 GSAC)

1500 (11 GTC)

1800 (14 GTAC)

Starting system

Electric-starter

Starting aid

Glow plugs

Lubrication System

System description

Forced lubrication by trochoid gear pump

Oil specifications

Use oil with 15W40 viscosity and no less than ACEA E5/E3 or

API CH-4/SJ quality

Oil pump

Trochoid gear type

Oil circuit capacity (l)

4,1

4,1

4,2

Lubrication oil pressure –nominal speed

(MPa)

0,29 –0,39 (3 –4 kgf/cm2)(2,9 –3,9 bar)

Min oil pressure - hot genset (MPa)

0,098 (1,0 kg/cm2)(0,98 bar)

Oil temperature –nominal speed (ºC)

60 - 95

Fuel System

System description

Electrical feed pump and mechanical injection pump

Fuel specifications

ASTM diesel diesel fuel No.2-D

Fuel injection pump

In-line type

Fuel injection nozzle

Throttle type

Cooling System

System description

Coolant circulation controlled by centrifugal pump with

thermostatic control and heat exchanger. Cooled exhaust

manifold.

Coolant specifications

KRAFFT ACU 2300 CC 50%

Coolant pump

Centrifugal type

Sea water pump

Centrifugal type

Coolant circuit capacity (l)

3,5

3,5

6,25

Thermostat valve

Start opening

End opening

+ 76,5ºC

+ 90ºC

Coolant temperature –nominal speed (ºC)

75 - 85

14

8 GTC

7 GSC

11 GTC

10 GTAC

8 GSAC

14 GTAC

DIESEL ENGINE

Inlet and

Exhaust

System

Air supply

Air cleaning by means of a dry-type air filter

Exhaust System

Cooled exhaust manifold

Dry exhaust manifold (optional equipment)

Electrical

System

Voltage –Polarity (V)

12 - ground

Alternator DC (A)

40

40

50

Starter motor (kW)

1,7

1,7

2

Glow plugs (A)

9,7 (10,5 V)

ALTERNATOR

General Information

Installation type

3-Phase

1-Phase

3-Phase

System cooler

Air fresh

Type

4 poles

Protection degree

IP23

Excitation system

Brushless

Power Factor (cos φ)

0,8

1

0,8

Insulation system

H

Voltage variation (V)

± 1

Frequency variation (Hz)

± 3

GENSET

General Information

Active stand-by power (kW/CV)

6,3 (8 GTC)

7,6 (10 GTAC)

6,6 (7 GSC)

8,0 (8 GSAC)

8,4 (11 GTC)

10,9 (14 GTAC)

Apparent stand-by power (kVA)

7,8 (8 GTC)

9,4 (10 GTAC)

6,6 (7 GSC)

8,0 (8 GSAC)

10,5 (11 GTC)

13,6 (14 GTAC)

Voltage (V)

400 / 230

(8 GTC)

480 / 277

(10 GTAC)

230 / 115

(7 GSC)

240 / 120

(8 GSAC)

400 / 230

(11 GTC)

480 / 277

(14 GTAC)

Frequency (Hz)

50 (8 GTC)

60 (10 GTAC)

50 (7 GSC)

60 (8 GSAC)

50 (11 GTC)

60 (14 GTAC)

Current Υ / Δ (A)

12 / 20

29 (7 GSC)

34 (8 GSAC)

17 / 28

Installation

Ø Int. Hose, sea water inlet (mm)

20

Ø Int. Hose, diesel fuel inlet (mm)

8

Ø Int. Hose, exhaust outlet1(mm)

50

Air admission displacement -max. rpm

(m3/h)

210-260

210-260

220-280

Minimum battery capacity (Ah)

60 (12V)

60 (12V)

80 (12V)

Length of battery wire (m)

≤ 1,5

Minimal section of battery wire (mm2)

60

Table 1. Technical Specifications 8 GTC / 10 GTAC / 7 GSC / 8 GSAC / 11 GTC / 14 GTAC

1

For each curve of 90º of the installation, must increase 10 mm (for lengths superior to 3 m).

15

Rev. 3

10 GSC

17 GTC

14 GSC

12 GSAC

20 GTAC

17 GSAC

DIESEL ENGINE

General Information

Type

Water-cooled, Diesel 4-stroke cycle

Direction of rotation

Anti-clockwise observing genset from flywheel side

No. of cylinders - arrangement

3 - in line

4 - in line

4 - in line

Allowable Exhaust Back Pressure (kPa)

Max. 6,57

Timing

Pushrod and rocker arm with gear driven camshaft in

crankcase

Bore (mm)

78

Stroke (mm)

92

Total displacement (c.c.)

1318

1758

1758

Compression ratio

22:1

22:1

22:1

Ignition sequence

1-3-2

1-3-4-2

1-3-4-2

Fuel injection timing

BTDC 17º

Injection pressure (kPa)

13,73 (140 kg/cm2)

Inlet and exhaust valve clearance - cold

genset (mm)

0,25

RPM (rpm)

1500 (10 GSC)

1800 (12 GSAC)

1500 (17 GTC)

1800 (20 GTAC)

1500 (14 GSC)

1800 (17 GSAC)

Starting system

Electric-starter

Starting aid

Glow plugs

Lubrication System

System description

Forced lubrication by trochoid gear pump

Oil specifications

Use oil with 15W40 viscosity and no less than ACEA E5/E3 or

API CH-4/SJ quality

Oil pump

Trochoid gear type

Oil circuit capacity (l)

4,2

6

6

Lubrication oil pressure –nominal speed

(MPa)

0,29 –0,39 (3 –4 kgf/cm2)(2,9 –3,9 bar)

Min oil pressure - hot genset (MPa)

0,098 (1,0 kg/cm2)(0,98 bar)

Oil temperature –nominal speed (ºC)

60 - 95

Fuel System

System description

Electrical feed pump and mechanical injection pump

Fuel specifications

ASTM diesel diesel fuel No.2-D

Fuel injection pump

In-line type

Fuel injection nozzle

Throttle type

Cooling System

System description

Coolant circulation controlled by centrifugal pump with

thermostatic control and heat exchanger. Cooled exhaust

manifold.

Coolant specifications

KRAFFT ACU 2300 CC 50%

Coolant pump

Centrifugal type

Sea water pump

Centrifugal type

Coolant circuit capacity (l)

6,25

8

8

Thermostat valve

Start opening

End opening

+ 76,5ºC

+ 90ºC

Coolant temperature –nominal speed (ºC)

75 - 85

16

10 GSC

17 GTC

14 GSC

12 GSAC

20 GTAC

17 GSAC

DIESEL ENGINE

Inlet and

Exhaust

System

Air supply

Air cleaning by means of a dry-type air filter

Exhaust System

Cooled exhaust manifold

Dry exhaust manifold (optional equipment)

Electrical

System

Voltage –Polarity (V)

12 - ground

12 / 24 (24V is optional) - ground

Alternator DC (A)

50

50 (12V) / 55 (24V)

Starter motor (kW)

2

Glow plugs 12V (A)

9,7 (10,5 V)

ALTERNATOR

General Information

Installation type

1-Phase

3-Phase

1-Phase

System cooler

Air fresh

Type

4 poles

Protection degree

IP23

Excitation system

Brushless

Power Factor (cos φ)

1

0,8

1

Insulation system

H

Voltage variation (V)

± 1

Frequency variation (Hz)

± 3

GENSET

General Information

Active stand-by power (kW/CV)

9,4 (10 GSC)

12,0 (12 GSAC)

13,2 (17 GTC)

15,6 (20 GTAC)

13,9 (14 GSC)

16,4 (17 GSAC)

Apparent stand-by power (kVA)

9,4 (10 GSC)

12,0 (12 GSAC)

16,4 (17 GTC)

19,5 (20 GTAC)

13,9 (14 GSC)

16,4 (17 GSAC)

Voltage (V)

230 / 115

(10 GSC)

240 / 120

(12 GSAC)

400 / 230

(17 GTC)

480 / 277

(20 GTAC)

230 / 115

(14 GSC)

240 / 120

(17 GSAC)

Frequency (Hz)

50 (10 GSC)

60 (12 GSAC)

50 (17 GTC)

60 (20 GTAC)

50 (14 GSC)

60 (17 GSAC)

Current Υ / Δ (A)

41 (10 GSC)

50 (12 GSAC)

24/41

61 (14 GSC)

69 (17 GSAC)

Installation

Ø Int. Hose, sea water inlet (mm)

20

ØInt. Hose, diesel fuel inlet (mm)

8

ØInt. Hose, exhaust outlet2(mm)

50

Air admission displacement -max. rpm

(m3/h)

220-280

240-300

240-300

Minimum battery capacity (Ah)

80 (12V)

80 (12V) / TBD

(24V)

80 (12V) / TBD

(24V)

Length of battery wire (m)

≤ 1,5

Minimal section of battery wire (mm2)

60

Table 2. Technical Specifications 10 GSC / 12 GSAC / 17 GTC / 20 GTAC / 14 GSC / 17 GSAC

2

For each curve of 90º of the installation, must increase 10 mm (for lengths superior to 3 m).

17

Rev. 3

1.3 Genset Limited Warranty

The genset is designed and built as a power unit for generating electrical energy: ALL USES

OTHER THAN THE PRESCRIBED APPLICATION AUTOMATICALLY RELEASE SOLÉ S.A. FROM LIABILITY FOR

DAMAGES THAT MAY ENSUE. In any event, the use of products other than those agreed upon at the

time of purchase RELEASES SOLÉ S.A. FROM ALL LIABILITY FOR DAMAGE TO THE GENSET OR PROPERTY

OR INJURY TO PERSONS.

Solé Diesel guarantees that at the time of shipment all its gensets comply with the provided

specifications and do not have any manufacturing defects.

The limited warranty provided by Solé Diesel enters into force from the time of sale to the first

end-purchaser or user of the genset. In the event that the product is not immediately delivered to the

end-customer, the warranty shall enter into force 6 months after the date of sale. Any limited warranty

period that has not elapsed can be transferred to the following purchaser(s).

Unless authorized otherwise by Solé Diesel, the warranty period is applied according to the

time elapsed in months from the date of purchase or the limit of hours of operation (whichever occurs

first).

GENSET FOR

PROFESSIONAL USE

GENSET FOR

RECREATIONAL USE

MONTHS

HOURS

MONTHS

HOURS

LIMITED WARRANTY COVERAGE PERIODS

12

1000

24

1000

EXTENDED COVERAGE PERIODS

-

-

24

1000

Table 3. Limited warranty coverage periods

Extended coverage (only recreational gensets) is applied to the following components:

-Engine block

-Cylinder head

-Crankshaft

-Camshaft

-Flywheel housing

-Timing gear housing

-Timing gear

-Conrod

RESTRICTIONS

Coverage:

a) The warranty covers any failure of the product under normal operating conditions caused by

a defect in manufacturing.

b) The warranty covers the labour costs necessary to replace and/or repair the defective

original components, according to Solé Diesel standards of excellence. The time period covered

for these operations is limited to 4 hours.

18

c) The warranty covers reasonable costs of travel required to carry out the necessary

operations. The travel distance is limited to 300 kilometers in conjunction with a travel time of

3 hours.

Excluded from coverage:

a) If Solé Diesel products are installed and used alongside other products not designed or

manufactured by Solé Diesel that affect their operation, the warranty shall apply exclusively to

the Solé Diesel products and shall not apply if the products from another manufacturer are

inappropriate for use alongside Solé Diesel products or are the cause of the failure or poor

operation of our products.

b) The warranty shall not apply if the revisions and maintenance services indicated in this

manual have not been adhered to properly.

c) Deterioration resulting from time of storage exceeding 6 months and/or storage conditions

that do not comply with the procedures described in this manual.

d) Deterioration resulting from not complying with the procedure for winter storage while the

engine is not in service, as described in this manual.

e) Faults due to negligence, lack of service, accidents, abnormal use and inadequate service or

installation.

f) Faults due to the use of components not manufactured or sold by Solé Diesel.

g) Faults due to electrical installations that do not comply with Solé Diesel design specifications

or are not expressly approved by Solé Diesel.

h) Faults due to the use of and operation with fuels, oils or lubricants that are not authorized by

Solé Diesel.

i) Faults due to water entering the cylinder(s) through the exhaust system.

j) Failure for general omission of the procedures described in this manual.

k) Components subjected to normal operating wear and tear.

l) Costs due to phone communications, loss of time or money, discomfort, launching,

grounding, removal or replacement of vessel parts or materials because the design of the vessel

makes it necessary to do so to access the genset, and damage and/or accidents caused as a

result of a failure.

For more information, consult the Warranty Manual.

AFTER-SALES SERVICE CONTACT

You can contact with the nearest authorized Solé Diesel dealer (see chart of Solé Diesel Dealers

in the Service Assistance section).

19

Rev. 3

Section 2 Transport, Handling and Storage

2.1 Receipt

When the genset is delivered make sure that the packing has not been damaged during

transport and that it has not been tampered with or that components inside the packing have been

removed (see information marked on covers, bases and cartons).

Place the packed genset as close as possible to the place of installation and remove the packing

material, checking that the goods supplied correspond to the order specifications.

NOTICE

If you notice damage or missing parts, inform SOLÉ S.A. after-sales departments and the carrier

immediately and forward photographic evidence of the damage.

After inspecting the goods if you notice damage, write a reservation on the delivery note. Have

the carrier countersign the note and advise SOLÉ S.A., preferably by mail (sole@solediesel.com).

2.2 Transporting and Handling the Packed Genset

When lifting and transporting the genset use EXCLUSIVELY a forklift or bridge crane of

appropriate load capacity, with chains equipped with safety hooks suitable for lifting the load.

The use of any other system automatically invalidates the insurance guarantee against possible

damage to the genset.

To unpack the genset, you must follow these steps:

1. Remove the cardboard crate.

2. Lift the genset using a forklift and suitable chains, which hook to the genset eyebolts.

3. Transfer the genset to the intended position of installation.

4. Remove the wooden base.

5. Begin installation operations.

Fig. 11. Packed genset

This manual suits for next models

7

Table of contents

Other Sole Diesel Portable Generator manuals

Sole Diesel

Sole Diesel 7 GS/GSC User manual

Sole Diesel

Sole Diesel 85 GTC User manual

Sole Diesel

Sole Diesel 85 GT User manual

Sole Diesel

Sole Diesel 29 GS/GSC User manual

Sole Diesel

Sole Diesel 29 GS User manual

Sole Diesel

Sole Diesel G-8M-3 User manual

Sole Diesel

Sole Diesel 20 GSC DNV User manual

Sole Diesel

Sole Diesel G-20T-15 User manual

Sole Diesel

Sole Diesel 7 GS User manual

Sole Diesel

Sole Diesel 165 GT User manual