Novusun CNC NVEMV1.1 User manual

M

Manual of NVEMv1.1

contect

Chapter1 Introduction..............................................................................................................................................1

1.1. ProductIntroduction............................................................................................................................ 1

1.2. Productsspecification.......................................................................................................................... 1

1.3. ProductsAppearance and struction and size....................................................................................... 2

1.4. substantivalexplanation....................................................................................................................... 3

1.5. Noting andWaring............................................................................................................................... 5

Chapter2 Connection...............................................................................................................................................6

2.1. Device PowersupplySolution............................................................................................................. 6

2.2. Productconnection define and method................................................................................................ 7

Chapter3 Software Installation..............................................................................................................................21

3.1. MACH3 Install.................................................................................................................................. 21

3.2. MACH3Registration.......................................................................................................................... 24

3.3. NVEMPlug-in installation................................................................................................................ 24

Chapter4 Usingofsoftware...................................................................................................................................25

C

hapter 1 Introduction

Chapter1 Introduction

1.1. ProductIntroduction

Novusun CNChas engagedintheNumericalcontrolindustryfor4 years,specializedin

theresearch,developmentand production ofvarious CNCcontroller systemswithhighquality

and highreliability.Weproduce theBrushless DCmotor,Stepper motordriver,and also 1to6aixs

CNCmotion controllers.。

NVEMv1.1 is the3-6 axis motion controller wespend 4 years to design.

NVEMv1.1 supportMach3 software and standardMPG,throughEthernetto

communicatewith computer,justusetheTwinetoconnectdirectlyortransfer with router.

NVEMv1.1 motion controller adoptstheARMdesignframework.TheARMdesign

includescommunication,codeanalytic,underlyingalgorithmand pulsegerneration. Rational

design,reliablecontrol,convenientoperation.

Thismanualintroducesoperation,connection andusagescheduleofourprofessional

motion controller forengravingmachine.Through alotofthedrawingtheuserscanlearn

quicklyhowto usethismotion controller.

1.2. Products specification

S12 ports photoelectricisolated inputinterfaceforordinarydigitaldata;

S10 ports photoelectricisolated outputinterfaceforordinarydigitaldata;

S1 port0-10Vspindlespeed analogoutputinterface(canchangeto PWM output);

Scan support3-6axis stepper systems,200KHzpulseoutputforeveryaxis;

SARM motion controlchip;

C

hapter 1 Introduction

Smain device is 12V-32VDCpower supplyinput,currentshould higher than0.5A;

SCompatiblewithMPGinput,supportthedigitaldisplayMPGfromourcompany。

1.3. ProductsAppearance andstruction and size

■NVEMv1.1 motion controller iswiththesealedshell structure,thereare4pcssetting

holes atthebottom.Wecan fix4pcs 4mm diameterholes atthecabinet,and install thecontroller

into thecabinet.Thecontroller appearance as theFigure 1-1and Figure 1-2 show:

Theproducts overall sizeis 163.1mm*80.8mm*27.8mm;

Thebottominstall sizeis101.4mm*42.5mm。

Figure 1-1. NVEMV1.1 frontappearance and size

C

hapter 1 Introduction

Figure 1-2. The othersideofNVEMV1.1and installation dimensions

1.4. substantival explanation

WhenoperatetheNVEM,where will bealotofEnglish abbreviation,nowwelistall of

themforyourkindlyreferences:

FRO:Feedingadjust:Duringtheoperating process,theFvaluealreadyset,and needto

adjustthecurrentfeeding speed, then wecanadjustFROvalueto realizeit.

SRO:Spindlespeedadjust: Duringtheoperatingprocess, theSvaluealreadyset,and need

to adjustthecurrentspindlespeed, then wecanadjustSROvalueto realizeit :

CurrentSpeed S#=settingS*SRO.

C

hapter 1 Introduction

SRJ:speed adjustmanually

During theoperatingprocess,asthemanualspeedalreadyset,and weneedtoadjustthe

currentspeed,and impossibletofixthevalueduringit isworking,thenwecanrevisetheSRJ

valueto realizeit.

Currentmanualspeed FS#=Settingmanualspeed*SRJ.

F:Feedingspeed,theunit ismm/min.ForexampleF=200,meanseveryminutefeeding

2000mm.

S:SpindleSpeed. Unit israd/min.ForexampleS=20000,means 20000 revolution/Minute.

Xaxis Coordinate

Yaxis Coordinate

Zaxis Coordinate

Aaxis Coordinate

Baxis Coordinate

Caxis Coordinate

Ready:ReadyMode.Inthemodewecando anyoperation,includeprocessingorvalues

modification orstarting2nd mode.

Reset: Resetmode.In this mode,it should stop everyoperation.

Step”:ManualStepMode.Every axiscandonductthemanualstepoperationatthismode.

MPG:MPGmode.Everyaxis can conducttheMPGoperation atthis mode.

C

hapter 1 Introduction

1.5. Noting and War

ing

Freefrom

exposure totheelectronicswithoutwaterproof

function.Pleaseenvironme

ntas dryas possible.This is theicon.

Wiringwar

ning, theIOinputterminalofthis equipmentsupportthe

equipmentwith source sw

itch(suchasInductiveproximityswitch.)Whenusing

suchkind ofswitch,

attention please:avoidthe+terminaland

po

wer supplytoconn

ect

outputterminalofspind

lecontrolalos haveacertainloadcapacity.Pleaseavoid

thisterminalconnectwit

h GND.in casethattheinteriorcomponents and parts be

brokendown.

Operation w

arning, Plea

connectingwiththemachi

netools.TheESTOP,limit and other things mustbe

p

erfected.Whencomes

across theemergancy,pleasepress theESTOPkeyatonce

orcutoffthepowerdirec

tly,thus avoidingthee

High volta

gedanger, theprimarydeviceis 18

supply.Voltageequipment.

Pls payattention to theelectricity, safetywhen conducting

theoperation

Noting and Wari

ng

Freefrom

exposure totheelectronicswithoutwat

erproof

function.Pleaseenvironmen

tas dryas possible.This is theicon.

rn

ing, theIOinputterminalofthis equipment

supportthe

equipmentwith source swit

ch(suchasInductiveproximityswitch.

)Whenusing

suchkind ofswitch, a

ttention please:avoidthe+terminaland

–

power supplytoconnec

twithGND.Thisequipment’sanalogyq

uantity

outputterminalofspindl

econtrolalos haveacertainloadcapacity.

Pleaseavoid

thisterminalconnectwith

GND.in casethattheinteriorcomponents

and parts be

Operation w

arning, Pleasedo thesecuritymeasures well w

hen

connectingwiththemachin

etools.TheESTOP,limit and other thi

ngs mustbe

perfected.Whencomesacr

oss theemergancy,pleasepress theESTO

Pkeyatonce

orcutoffthepowerdirect

ly,thus avoidingtheequipmentdamageand

casualty.

High voltag

edanger, theprimarydeviceis 18-32VDCpo

wer

supply.Voltageequipment.P

ls payattention to theelectricity, safetywhen

conducting

Freefromexposure totheelectronicswithoutwater

proof

rning, theIOinputterminalofthis equipmentsuppo

rtthe

equipmentwith source switch(suchasInductiveproximityswitch.)W

henusing

–

terminalof

withGND.Thisequipment’sanalogyqu

antity

outputterminalofspindlecontrolalos haveacertainloadcapacity.

Pleaseavoid

thisterminalconnectwith GND.in casethattheinteriorcomponents

and parts be

sedo thesecuritymeasures well wh

en

connectingwiththemachinetools.TheESTOP,limit and other things

mustbe

perfected.Whencomesacross theemergancy,pleasepress theESTO

Pkeyatonce

quipmentdamageand c

asualty.

32VDCpow

er

supply.Voltageequipment.Pls payattention to theelectricity, safetywhen c

onducting

C

hapter 2 Conection

Chapter2 Connection

2.1. Device PowersupplySolution

Thepower supplysolution inthefieldoftheIndustrialautomation isalwaysvery

complicated,thereisalotoftheGND,nowwedescriptthestructure ofthepower supply asbelow:

Thepower supplystructure astheFigure 2-1,mainpower supplyinputand MPGmoduleand

stepper controloutputmoduleare common GND,Limitedand Estop inputmoduleand Spindle

speedadjustM3/M8/M1 modulearecommon GND,betweenmainpower supplyand output

modulethere arephotoelectricisolation.Theinputsoflimitedswitchand Estop and so on are

Common anode,insideofthedevice,thereis+12VDCascommon+,no needtoconnectexternal

power supply. BasedonthereferenceofoutputGND interface,outputa0-10Vadjustablevoltage

toadjustthethespindlespeed,M3/M8/M10 digitaloutputinterfaceisopen-GND.Ifconnectan

externalrelay,need to outputGND to refer to,and givetherelayan externalpower supply.

Figure 2-1. Powersupplystructure

C

hapter 2 Conection

2.2. Productconnectiondefine andmethod

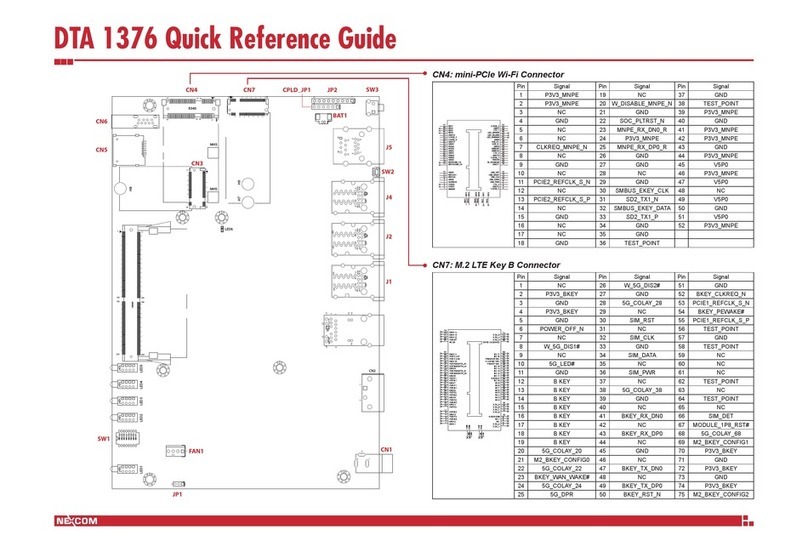

Figure 2-2. Productwiring section andinterface summary

AstheFigure 2-2showed,theconnection ofthecontroller includespower supply

interface,Ethernetconnection interface,MPGinterface,Stepper/Servocontroloutput

interface,spindlecontroloutputinterface,Estop and limitedswitchand toolsetting inputinterface

and so on. Nowwedescriptthemin details as below.

2.2.1 Steppermotor control interface

AsFigure2-2showed,No.1 terminalblockis6axisstepper drivercontroloutputinterface,

fromlefttoright,there areX,Y,Z,A,,B,C6axisoutput,it’scommon anode,thecableconnection for

eachaxisisCOM+/CP-/DIR-,COMiscommon+,CPisPulse-,DIRisdirection-.Connection

showed as Figure 2-3.COM+connectwith theSP+and DIR+.

Pin mark Axis Definition

COM+ Commom+ common anode+5V

C

hapter 2 Conection

CPX- Xaxis Pulseoutput-forXaxis

DIX- X axis Directrion output-forXaxis

CPY- Y axis Pulseoutput-forYaxis

DIY- Y axis Directrion output-forYaxis

CPZ- Z axis Pulseoutput-forZaxis

DIZ- Z axis Directrion output-forZ axis

CPA- A axis Pulseoutput-forAaxis

DIA- A axis Directrion output-forAaxis

CPB- B axis Pulseoutput-forBaxis

DIB- B axis Directrion output-forBaxis

CPC- C axis Pulseoutput-forCaxis

DIC- C axis Directrion output-forCaxis

Table 2-1 Stepper drivercontrol interface define

C

hapter 2 Conection

Figure 2-3. Stepper driverconnection

2.2.2 Spindle control output

Wedefinetheinterface fromleftare:GND1(OutputGND),VSO(0-10Vadjustablespeed

output),INDEX(spindlespeedfeedbackinput),OUT1(common outputport1),OUT2(common

outputport2),.

TakeNowforeuerinverterastheexample.Spindlecontroloutputand theinverter connection

showed as Figure 2-4.IfACM and DCM are closed,onlyneed to connectoneport.

IfneedtheMach3toshowtherealintimespindlespeed,justfixonehall device,every

revolution send onepulsebetweenINDEXand GND1,pulsevoltageis 5V-10V.

C

hapter 2 Conection

Figure 2-4. spindle controloutput andinverterconnection

VSOrealoutputvoltage=10V*s spindlesettingspeed/maxspindlespeed.Forexample,ifmax

spindlespeedis24000,currentspindlespeedisS=18000,so theVSOoutput

voltage=10*18000/24000=7.5V.

Max.spindlespeedsettingportsasshowedsaFigure2-5,openit fromPulleyfromMenu

config.ThecurrentspindlespeedcanbesetbySdirectiveorMach3spindlesettingspeedmodule.

Figure 2-5. Max spindle speed setting position

C

hapter 2 Conection

2.2.3 Common IOoutput interface

Common IOoutputincludeOUT1,OUT2 on thespindleinterface,totally10 portsIO

output,open drainoutput,internalstructureas Figure2-5..

Figure 2-6. OUT1-OUT10internal structure

NowjustmakeaswitchbetweenOUTX(X=1-10)and GND,tocontroltherelay

output,theconection astheFigure 2-6.Externalpower supplyneedtoaccordwiththerelay

specification,theinternaloptocoupler GND opencircuit onlycanabsorbless than50mAcurrent,if

relayabsorbthecurrentover 50mA,plsadd currentamplifier.IntheFigure connectwithOUT3,the

others similar.

C

hapter 2 Conection

Figure 2-7. OUTX connect with external relay method

2.2.4MPG connection

TheMPGporttotallyhave18 wiringterminals, and thereference ofeachwiring

terminaldefinition istable2-2. Thereferenceofcorrespondingrelationbetweensystemand

MPGwiringis table2-3and table2-4.

Pinmark Definition Notes

GND MPG Ground MPG power supply GND.

TXD MPGserialcommunication

OutputPort

Forthe digitaldisplayMGPcommunication

RXD MPGserial

communicationinputPort

Forthe digitaldisplayMPGcommunication

100X 100X multiplication

switch

shortconnectwith GNDmeans100X

multiplication,cutoffmeansno pulse

10X 10X multiplication

switch

shortconnectwithGND means10X

multiplication,cutoffmeansno pulse

C

hapter 2 Conection

1X 1 X multiplication

switch

shortconnectwithGND means1X

multiplication,cutoffmeansno pulse

ESTOP MPG Estop shortconnectwith GNDmeansEstop

effective,cutoffshowinvalid

C-IN CAxisselected switch Shortconnectwith GNDmeanasselectingC

aixs,cutoffmeansdont select

B-IN BAxisselected switch ShortconnectwithGND meanasselectingB

aixs,cutoffmeansdont select

A-IN AAxisselected switch Shortconnectwith GND meanasselecting A

aixs,cutoffmeansdont select

Z-IN ZAxisselected switch Shortconnectwith GND meanasselecting Z

aixs,cutoffmeansdont select

Y-IN YAxisselected switch Shortconnectwith GNDmeanasselectingY

aixs,cutoffmeansdont select

X-IN XAxisselected switch ShortconnectwithGND meanasselectingX

aixs,cutoffmeansdont select

VDD5 MPGpowersupply5V

output

MPGpowersupply5Voutput

WHA+ MPG A Phases Positive MPG A Phase differential Input Positive

WHB+ MPG B Phases Positive MPG B Phase differential Input Positive

WHA- MPG A Phases Negative MPG A Phase differential Input Negative

WHB- MPG B Phases Negative MPG B Phase differential Input Negative

Table 2-2 NVEM on MPG’sdefine and explaination

C

hapter 2 Conection

NVEMPINNo. MPGpinNo. and color

Estop C Lightblue

1multiplication 1 X1 grey

10multiplication 10 X10 Black/Grey

100multiplication 100 X100 Orange

Xselecting X Yellow

Yselecting Y Black/Yellow

Zselecting Z Brown

Aselecting 4 Black/Brown

Bselecting 5 Pink

Cselecting 6 Pin/Black

APhase + A+ Green

APhase - A- Purple

BPhase + B+ White

BPhase - B- Purple/Black

GND 0V/CN/COM Black,Black/light

blue,black/orange

+5V-W +5V red

Table 2-3 ConnectionbetweenDifferential MPG and NVEM

Note:Ityou wanttousethesingle-terminalMPG(namelythereisno A-B-MPG),please

look atthewiringtable,thetable2-4forreference.Asfortheunlistedone,pleasetakethe

differentialMPGwiringmode.

C

hapter 2 Conection

NVEM PinNo. MPG Pin No. and color

WHA+ A+ green

WHA- 0V Black

WHB+ B+ white

WHB- 0V Black

Table 2-4 ConnectionBetweenSingle MPGandNVEM

2.2.5 Main power supply input Interface

AstheFigure2-2show,No. 5positioninterface isthemainpower supplyinput,marked +”is

thepower supplypositive,theother onewasn’tmarkedisthenegative,power supplyvoltageis

12-32VDC,Currentmustbenotless then 1A.

2.2.6 Commnicationexternal interface

AstheFigure2-2showed,themarkedNo. 6position iscommunication externalport,thisport

wasn’tdefinedyet.

2.2.7Estop limitedTool setting input interface

.AstheFigure2-2showed, MarkedNo. 7position istheEstop limitedect.theyare the

opticalisolatedInputinterface,fromtheleft,thereare12V,STOP,12V,PROB,12V,INP3,INP4,INP5,

INP6,INP7,12V,INP8,INP9,INP10,INP11,INP12,GND.Here STOPisINPUT1 ,and PROB

isINPUT2. Internalstructure FigureofInputinterface see as Picture 2-8

ESTOPconnectwith NVEM see as Picture2-9.

C

hapter 2 Conection

Figure 2-8. Internalstructure drawing ofInputinterface

Figure 2-9. Estop input connection

ToolSettingConnection see as Picture 2-10

C

hapter 2 Conection

Figure 2-10. ToolSetting Connection Drawing

2 lines ProximitySwitch/ordinaryfrettingswitch drawingsee as Picture 2-11

Figure 2-11. 2 linesProximitySwitch/ordinaryfrettingswitch drawing

3 lines ProximitySwitchconnection Figure2-11,brown cableforProximityswitch connect

with 12V,Blackcableconnectchannel,bluecableconnectwith GND1.

C

hapter 2 Conection

Figure 2-12. PNP3 linesProximitySwitch connection drawing

2.2.8 Parameteradjust interface

Bythis adjustinterface,user can useamuti-position switch and adigital

potentionmeter(simpleencoder) to modifyFRO,SROand SJR.Wiringmethod see as figure2-13

simpleencoder's COMABconnectto 12V/FHA/FHB,and muti-position switch connectto 12V

SROSJR.If12Vdon'tconnectto SROorSJR,currenteffectiveparameter isFRO, if12Vconnect

to SRO,currenteffectiveparameteris SRO,and if12Vconnectto SJRcurrenteffectiveparameter

is SJR.

Table of contents

Other Novusun CNC Network Hardware manuals