Page 2

*

Suction Piping: The suction pipe must be kept free from

air leaks. The suction pipe must have a gradual slope upward

to the pump. Avoid any fittings which may cause an air trap.

A check valve is a built-in feature and no foot valve is

required.

Discharge Piping: A gate valve and union should be

installed in the discharge line. For removal of the pump for

service, close the gate valve, and disconnect at the union.

Priming the Pump: A tee installed in the discharge opening

of the pump and provided with a priming plug at the top

position; will enable you to fill the pump with water. Once

filled and the priming plug replaced, the pump will prime.

The priming time depends upon the vertical and horizontal

distance between the pump and the water level. The pump

should prime itself time after time as long as the built-in

check valve functions.

CAUTION: DO NOT run the pump before filling the pump

case with liquid, as it may damage the seal.

Storage of Pump: Drain liquid from pump to prevent

freezing. It is recommended that a good rust inhibitor be

put in the liquid and to prevent excessive corrosion. Be sure

motor is kept dry and covered.

When restoring the use of the pump, replace all plugs and

make sure all connections are tightly sealed. After a complete

check is made, make the initial prime according to directions

under the section, Priming the Pump.

ELECTRICAL

WIRING:

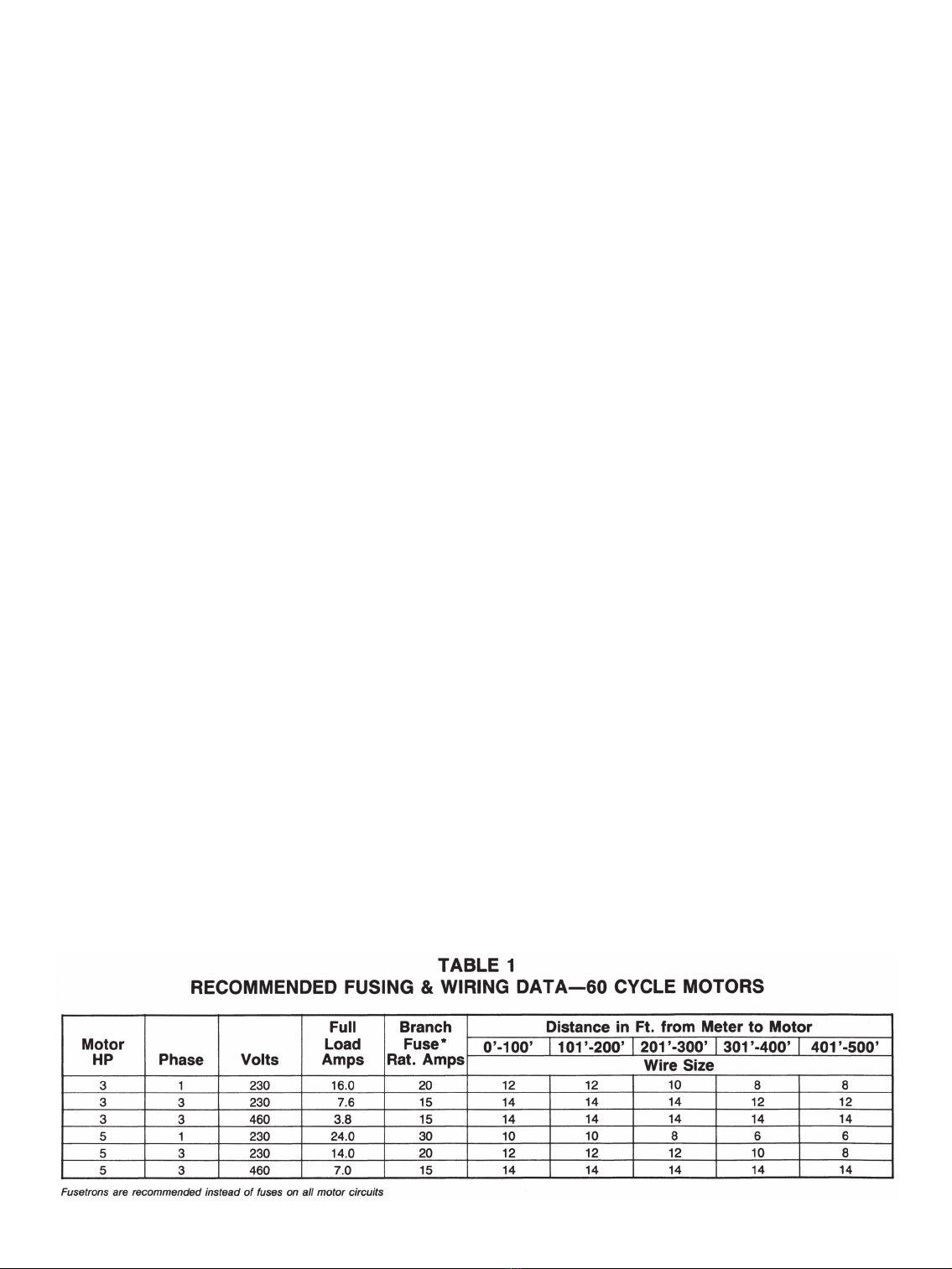

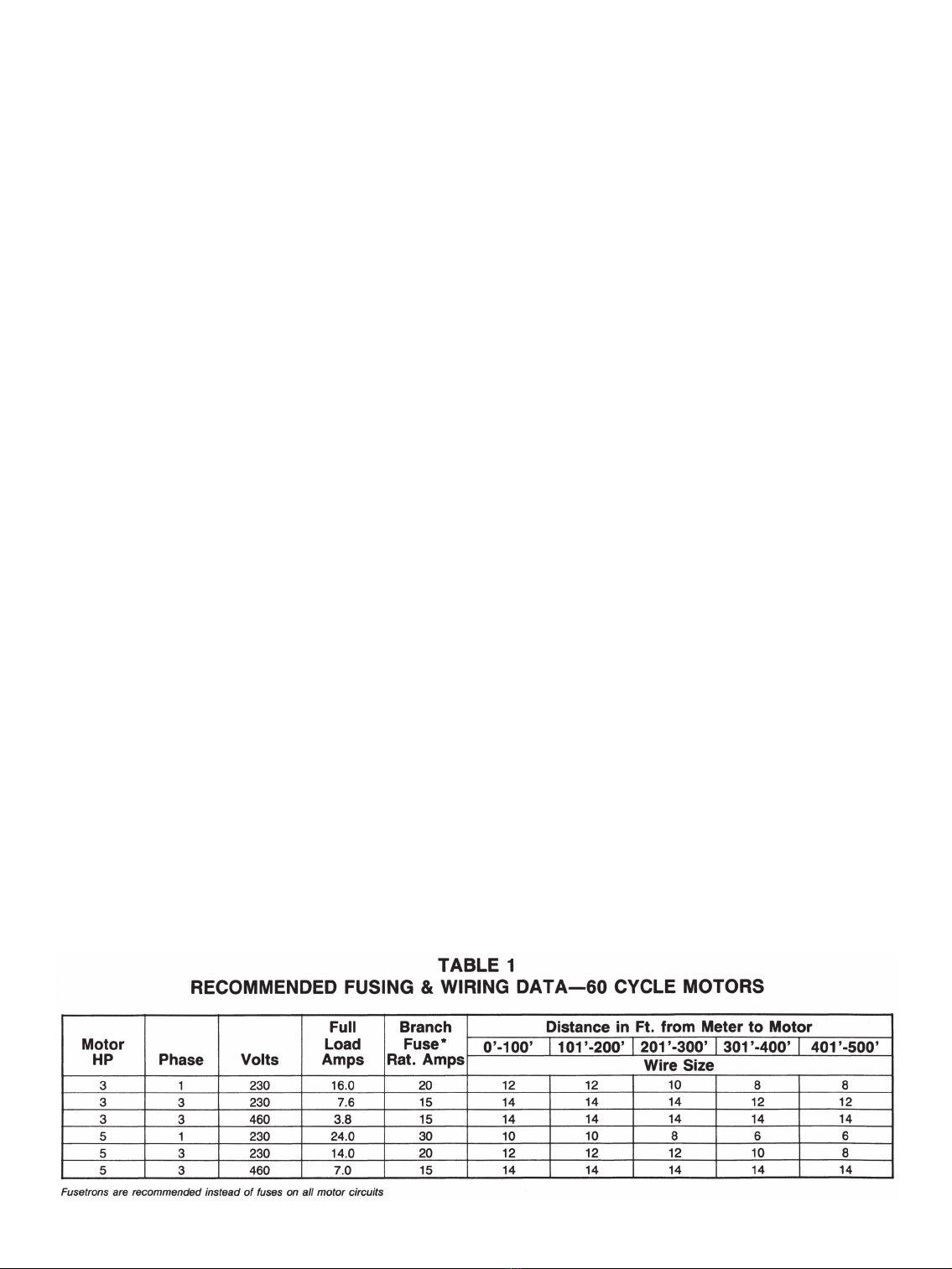

Check wiring and fuse charts before connecting wires to

service lines. Make sure the voltage and frequency of the

power supply agrees with what is stamped on the motor

nameplate. If in doubt, check with the power company.

Single Phase: Determine incoming voltage to motor. Where

possible, use 230V. Connect wiring to terminal board located

inside conduit box cover. Be sure voltage connections agree

with wiring diagram on motor nameplate.

Three Phase: Three phase motors require magnetic starters,

and can run in either direction, depending on how they are

connected to the power supply.

To Check for Proper Rotation: Remove the motor end

cover. This exposes the motor shaft. If hook-up is correct,

the shaft will rotate clockwise. If rotation is not clockwise,

reverse any two leads to the starter. The rotation will now be

correct.

GROUNDING THE MOTOR:

WIRING TO THIS PUMP MUST BE INSTALLED AND

MAINTAINED IN ACCORDANCE WITH THE

NATIONAL ELECTRICAL CODE OR YOUR LOCAL

ELECTRIC CODE. IF MORE INFORMATION IS

NEEDED, CALL YOUR LOCAL LICENSED

ELECTRICIAN OR YOUR POWER COMPANY.

Permanently ground the motor in accordance with the

National Electrical Code Article 250 or applicable local

codes and ordinances. It is recommended that a permanent

ground connection be made to the unit using a conductor of

appropriate size from a metal underground water pipe or a

grounded lead in the service panel. Do not ground to a gas

supply line. Do not connect to electric power supply until

unit is permanently grounded. Connect the ground wire to

the approved ground and then connect to the terminal

provided.

A metal underground water pipe or well casing at least 10 ft.

long makes the best ground electrode. If plastic pipe or

insulated fittings are used, run ground wire directly to the

metal well casing or use ground electrode furnished by the

power company.

There is only one proper ground connection on the motor. It

is located under the motor canopy and is painted green and

identified as GRD. Ground connection must be made to this

terminal. See wiring diagram on next page.

*