Gasket

Module Module

Mounting

foot

c/l of

mounting

fixing

2

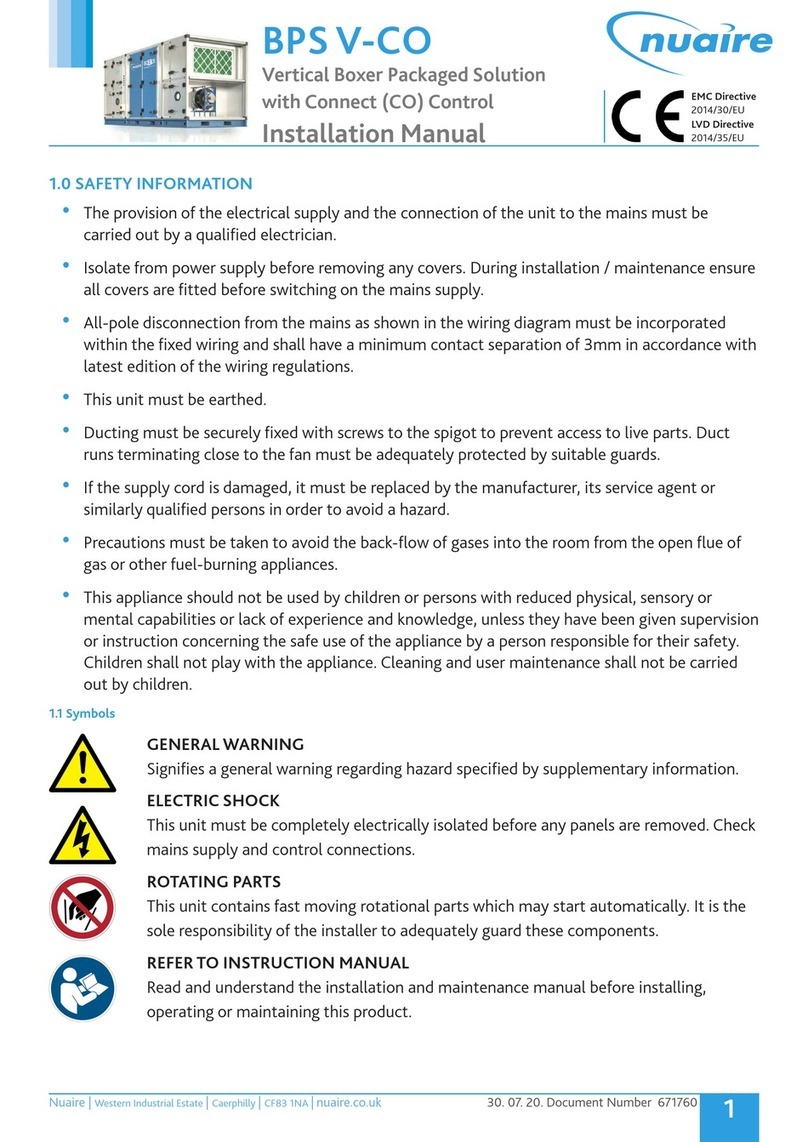

Fig. 3 Fitting a cleat

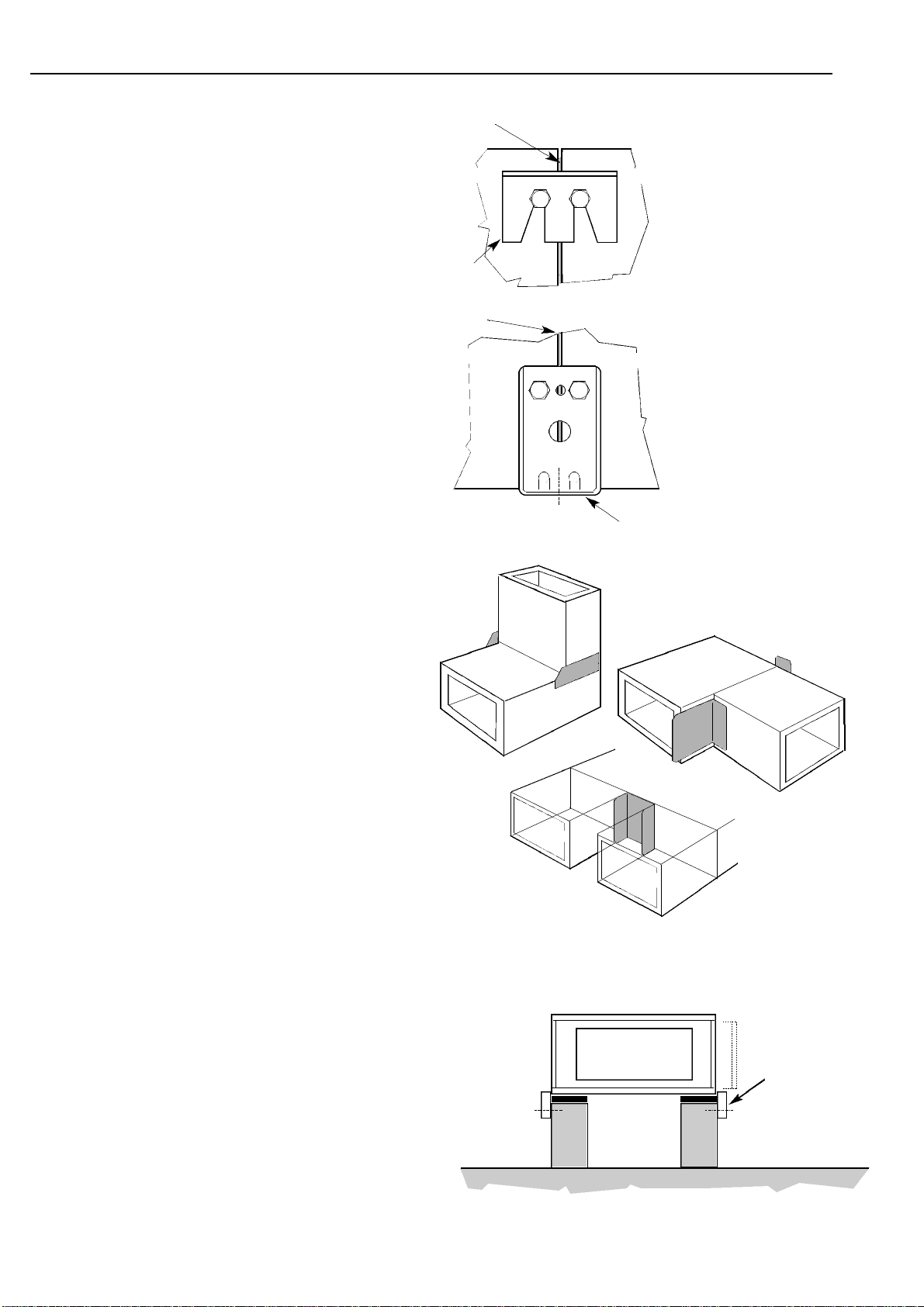

Fig. 4 The mounting foot

Fig. 5 Closure Plates used on Bend and Heat Exchanger modules.

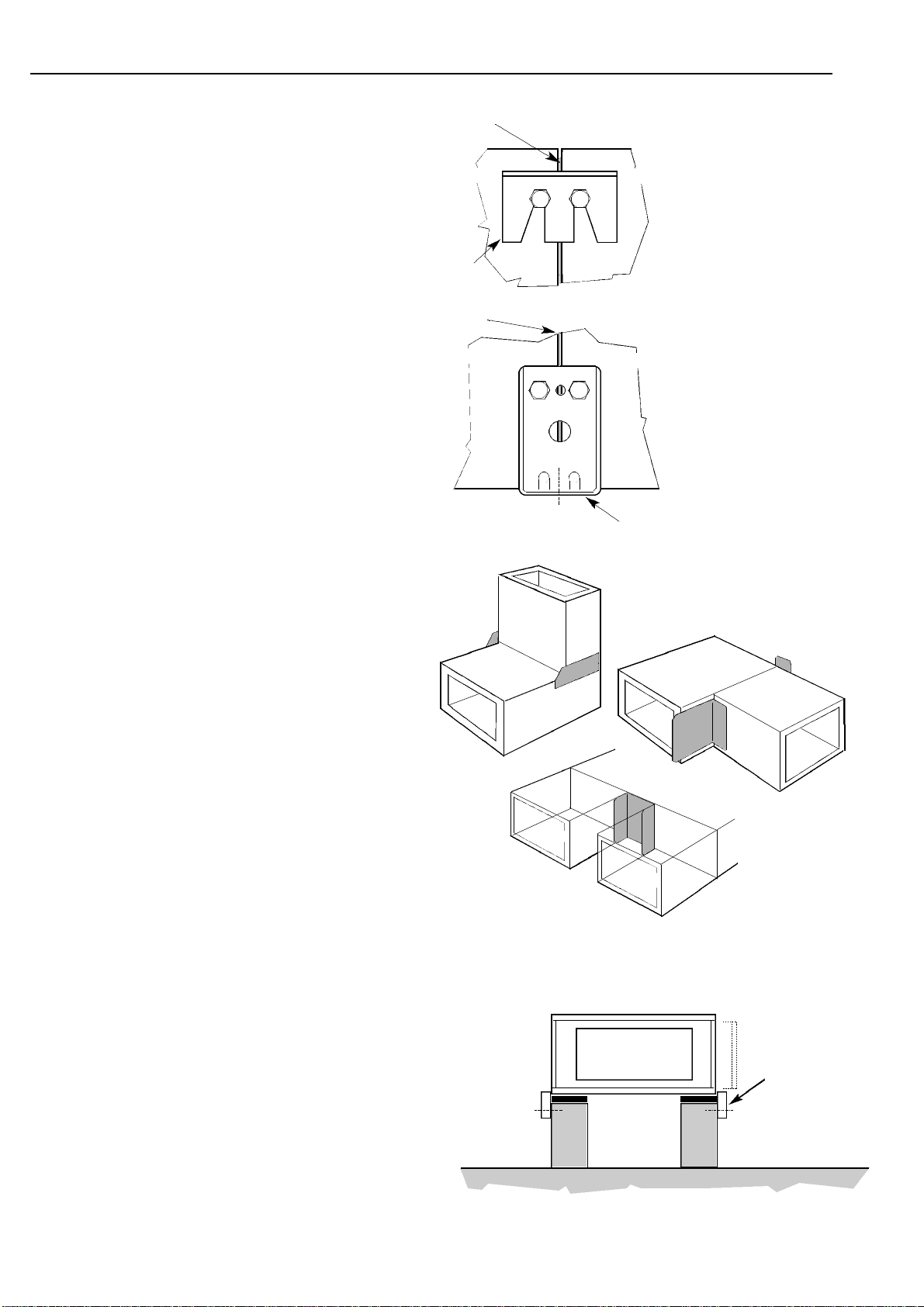

Fig. 6 Simple builders upstand mounting assembly.

Installation Options

The Boxer range can be installed using a number of

different methods. This provides flexibility to cater for

particular on site conditions. Note that for units delivered as

individual modules; the spigot plates that connect with the

ductwork are always fitted to the fan module. These should be

removed in preparation for fitting to the appropriate modules at

each end of the assembly.

Assembly of the modules

The module to module assembly is similar for all the unit sizes.

Each module is constructed from six panels. End panels are

designed to attach to the corresponding panel in the adjacent

module and provide mounting points for the assembly.

The modules are assembled together using cleats, mounting

feet or, for certain modules, closure plates.

All fixings necessary are provided. The fixings are vibration

proof.

Clamping cleats are manufactured in heavy gauge mild steel

and are designed to draw the end panels together into the

correct position for gasket compression. For fitting, slacken the

relevant vibration-proof bolts to show approximately 4mm of

exposed thread and slide the cleat into position. A sharp blow to

the folded edge will then engage the cleat. (See fig. 3). Tighten

the bolts to a torque of .........Nm.

Mounting Feet, pressed in mild steel, provide for both

attachment and mounting of the assembly. The vibration proof

bolts should be tightened to a torque of ........Nm.

Closure Plates, are supplied with the Bend Modules and also

the Heat Exchanger Modules. The vibration proof bolts should

be tightened to a torque of ........Nm.

NOTE:

In all cases when positioning adjacent modules, ensure

that the gasket material is not displaced.

Unit Mounting (floor or roof)

On a smooth and level surface, capable of supporting the

assembled weight of the units, no assembly frame is required.

This has the advantage of minimising the overall height of the

unit.

An uneven mounting surface will impose undue strain upon

the assembly. In extreme cases this may cause leakage and

component failure. A simple builders work upstand may be

used to raise the equipment from the floor level. (See fig. 6).

Note: this will be necessary where cooling coils and heat

exchangers are specified in order to allow fitting of the

appropriate condensate drainage trap.

Construct the upstand to support the base periphery of the

assembly. Position the modules in the correct order and a

assemble using clamping cleats. Mounting feet should be used,

at least at every other joint, secured to the mounting surface. It

is normal practice to fit a resilient matting between the unit and

the mounting surface.

Where supplied with a base frame the module assembly needs

only to be positioned and secured to the floor. Again, the

surface should be level and additional height may be required

for drainage traps.

Assemblies are supplied in maximum lengths of 2.4metres.

Longer assemblies must be joined on site (fixings supplied).

Gasket

Module

Cleat

Module

o

o

o

o

o

o

oo

Timber securing battens

used to retain the assembly

in position.

Note that the battens must

not be placed too high

around the assembly which

would interfere in removal

of the side access panels

Installation & Maintenance BOXER AIR HANDLING UNITS