2

27. 04. 21. Document Number 671182

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

GENIEInstallation Manual

1.2 Important Information

This manual contains important information on the safe and

appropriate assembly, transport, commissioning, operation,

maintenance, disassembly and simple troubleshooting of the product.

While the product has been manufactured according to the accepted

rules of current technology, there is still a danger of personal injury or

damage to equipment if the following general safety instructions and

the warnings contained in these instructions are not complied with.

•Read these instructions completely and thoroughly before

working with the product.

•Keep these instructions in a location where they are accessible

to all users at all times.

•Always include the operating instructions when you pass the

product on to third parties.

1.3 Personal Protective Equipment

The following minimum Personal Protective Equipment (PPE) is

recommended when interacting with Nuaire product:

•Protective Steel Toed Shoes - when handling heavy objects.

•Full Finger Gloves (Marigold PU800 or equivalent) - when

handling sheet metal components.

•Semi Fingerless Gloves (Marigold PU3000 3DO or equivalent)

- when conducting light work on the unit requiring tactile

dexterity.

•Safety Glasses - when conducting any cleaning/cutting operation

or exchanging filters.

•Reusable Half Mask Respirators - when replacing filters which

have been in contact with normal room or environmental air.

Nuaire would always recommend a site specific risk assessment by a

competent person to determine if any additional PPE is required.

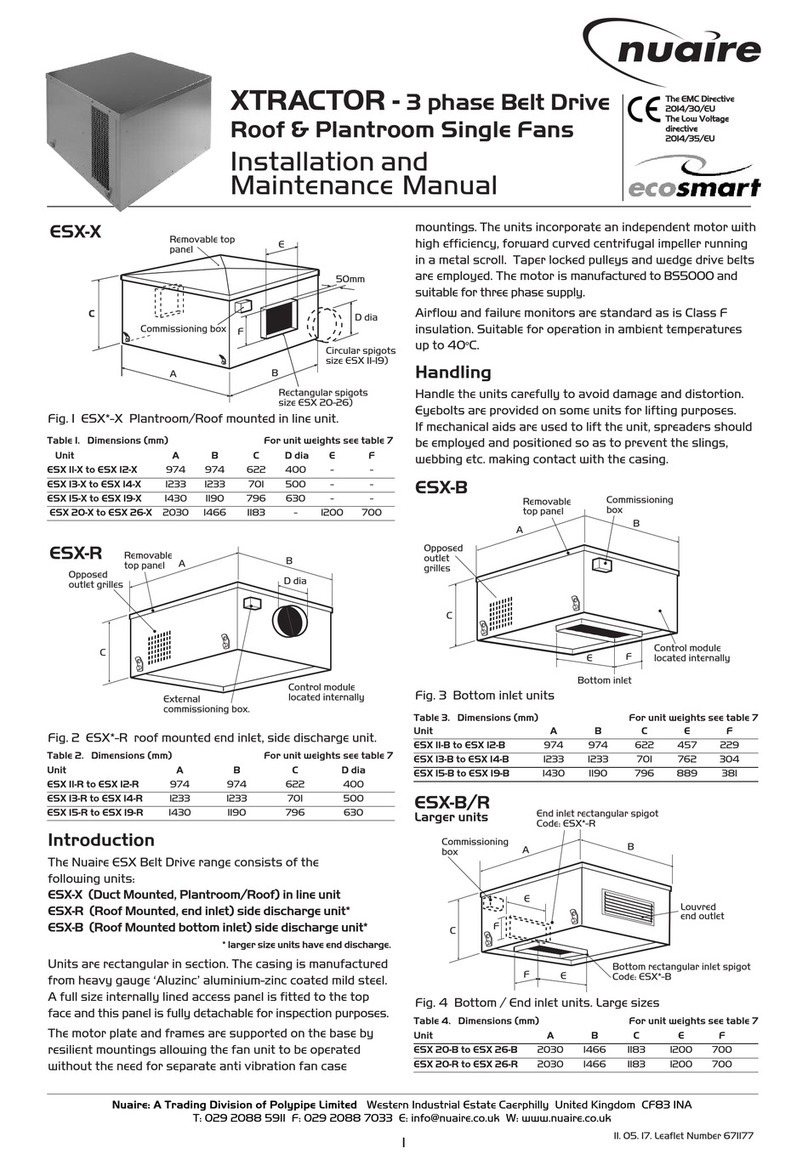

2.0 INTRODUCTION

The Genie range of fans has been specifically designed to ventilate

small rooms such as toilets, bathrooms, cloakrooms etc. and can be

surface and recessed mounting. An optional window mounting kit is

available for this unit, code ref: WINKIT.

Air entering the unit passes through a washable filter fitted to the front

cover. Backdraught shutters, retained in the closed position when fan is

not running, are fitted to the base plate.

Motor has sealed, self lubricating bearings and “heatseeker” thermal

overload protection. The fan/ motor assembly is retained by spring clips

to simplify maintenance.

Interchangeable plug in electronic control modules can incorporate:

•Run-On Timer

•Humidistat

•Continuous Low Duty With Boost

As a safety feature the fan/motor assembly is automatically

disconnected when the electronic control module is removed.

When installing Genie units for remote switching it is important

that the pull cord (if fitted) is removed.

It is recommended that the unit is switched off (by the pull cord)

before cutting. Cut the pull cord inside the unit a little way beyond

the control module.

2.1 Code Description:

GENIE - H 12

1- 2 3

1. Range: GENIE: Universal Surface Mounted Fans

2. HX Type: No Affix: On/Off Control Via Pull Cord / Remote

Switch*

PIR: On/Off Control Via Pir (230 V Only)

S: On/Off Control With Integral Run-On

Timer Via Remote Switch* Only

H: On/Off Control With Integral Humidistat

Via Pull Cord / Remote Switch*

X: Continuous Trickle With Boost Via Pull

Cord / Remote Switch*

XH: Continuous Trickle With Boost Via Pull

Cord / Remote Switch*

3. Supply Voltage: No Affix: 230 V

12: 12 V

*Light switch or similar (not supplied).

Genie units are supplied with a finishing frame for use in semi-

recessed applications.

WINKIT: Optional window mounting kit.

3.0 MECHANICAL INSTALLATION

Installation must be completed by competent persons, in accordance

with good industry practice and should conform to all governing and

statutory bodies i.e. IEE, CIBSE, etc.

Before commencing work make sure that the unit is electrically

isolated from the mains and switched live supply.

3.1 Surface Mounting

It is assumed that a solid mounting position has been selected,

compatible ductwork has been installed and passages for ductwork

from the outlet spigot as well as electrical connection have been

prepared.

The discharge spigot is 98mm Ø OD. The hole in the structure

should therefore be of a dimension to accommodate any ducting or

cavity lining used.

Base drill pattern superimposed in Section 10.0 on page 8.

1 Wall Mounted Unit