Installation and Maintenance QUIETWIN DIRECT DRIVE TWINFANS

8

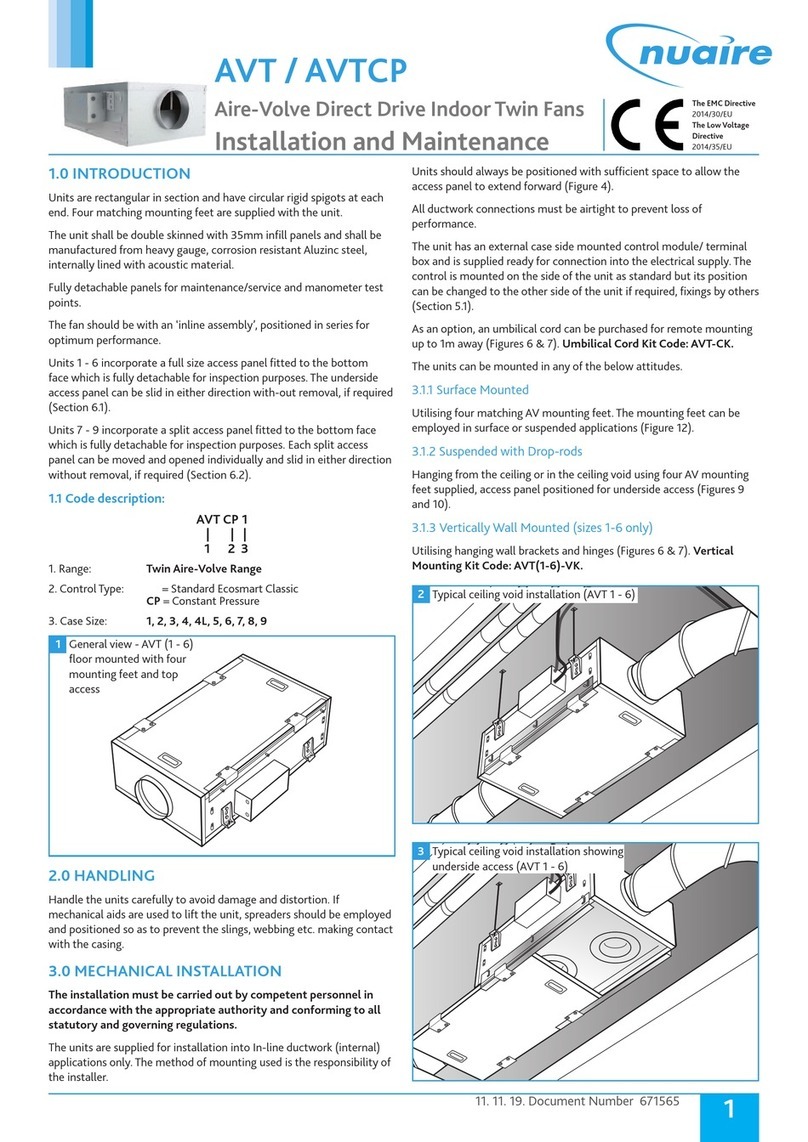

Replacement of Parts

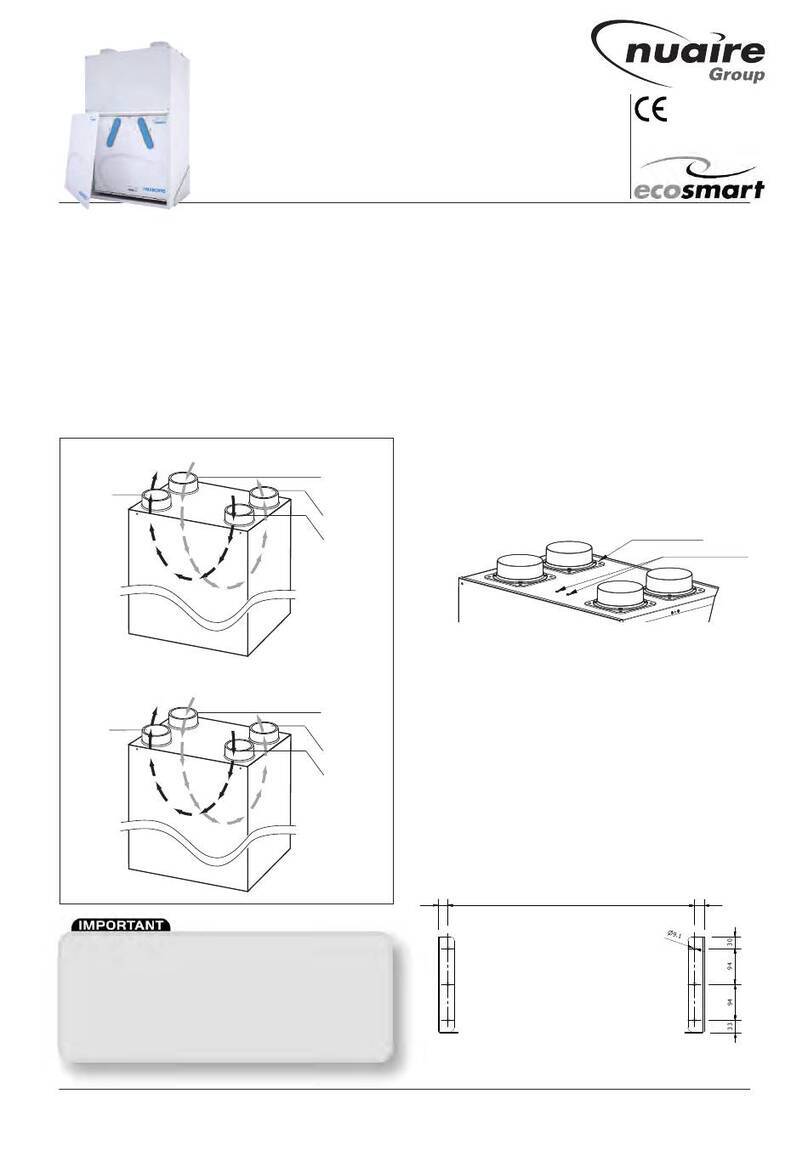

The only item of the fan units unit likely to require replace-

ment are the fan/motor assemblies due to a failed motor or

damaged impeller. In either eventuality the complete fan/

motor assembly must be removed from the unit case.

NOTE:

BEFORE COMMENCING WORK, ELECTRICALLY

ISOLATE THE FAN UNIT AND / OR THE

ASSOCIATED NUAIRE CONTROL, IF FITTED,

FROM THE MAINS SUPPLY.

Remove the access cover. Disconnect the incoming wiring

from the connection box (located on the fan scroll) on the

particular fan/motor assembly to be removed. Support the

weight of the fan/motor assembly and remove the mounting

screws and washers. Lift the assembly out of the case.

After replacing the faulty item, refit the fan/motor assembly

and reconnect the incoming wiring to the fan mounted con-

nection box. Replace the access cover.

Schedule of Parts

When ordering spares please quote the serial number of the

unit together with the part number. If the part number is not

known please give a full description of the part required. The

serial number will be found on the identification plate

attached to the unit casing

Controls Application Service (CAS)

A team of Engineers and technicians is available to provide

pre and post order support.

We are on hand to provide help and advice from the most

basic use of any NuAire equipment to the more complex

applications, maximising on the versatility of our control

products.

Telephone: 029 2085 8585

Facsimile: 029 2085 8586

Maintenance (General)

ISOLATION

BEFORE COMMENCING WORK MAKE SURE

THAT THE UNIT AND NUAIRE CONTROL, IF

FITTED, ARE ELECTRICALLY ISOLATED FROM

THE MAINS SUPPLY.

Maintenance Intervals

The first maintenance should be carried out three months

after commissioning and thereafter at twelve monthly inter-

vals. These intervals may need to be shortened if the unit is

operating in adverse environmental conditions, or in heavily

polluted air. NOTE: Failure to maintain the unit as recom-

mended will invalidate the warranty.

Lubrication

Motors are fitted with sealed for life bearings and therefore

require no further lubrication.

General Cleaning and Inspection

Clean and inspect the exterior of the fan unit and associated

controls etc.

Remove the access panel from the fan unit. Inspect and, if

necessary, clean the fan and motor assemblies and the interi-

or of the case. If the unit is heavily soiled it may be more

convenient to remove the fan / motor assemblies.

Check that the shutters are free to move smoothly and that

they seal the appropriate fan outlet effectively.

Clean and inspect each fan and motor assembly as follows;

taking care not to damage, distort or disturb the balance of

the impeller.

a) Lightly brush away dirt and dust, paying particular

attention to any build up at the motor ventilating slots.

If necessary, carefully remove with a blade or scraper.

b) Stubborn dirt at the impeller may be carefully removed

with a stiff nylon brush.

c) Check all parts for security and general condition.

Check that the impeller rotates freely.

Refit the assemblies to the unit (see Replacement of Parts)

then replace the access covers

If NuAire controls and or remote indicators are fitted,

remove the covers and carefully clean out the interiors as

necessary. Check for damage.

Check security of components. Refit the access covers.

Service

As a manufacturer NuAire provides you with factory trained

Service Engineers.

Our Engineers are supported by a comprehensive range of

spare parts 'off the shelf'.

If you are an industrial or commercial user, you may be

interested in details of NuAire's regular maintenance Service

Contracts. This is a worthwhile service that helps you get

the most from our products.

Our Service Department will be happy to give you more

information.

Please telephone: 029 2085 8585

Table 6 Spares listing

Unit

code

Blower assembly

c/w motor.

QTI 1

QTI 2

QTI 3

QTI 4

QTI 5

QTI 6

QTI 7

QTI 8

772819

772820

772821

772822

772823

772824

772825

772825