SPECIFICATIONS

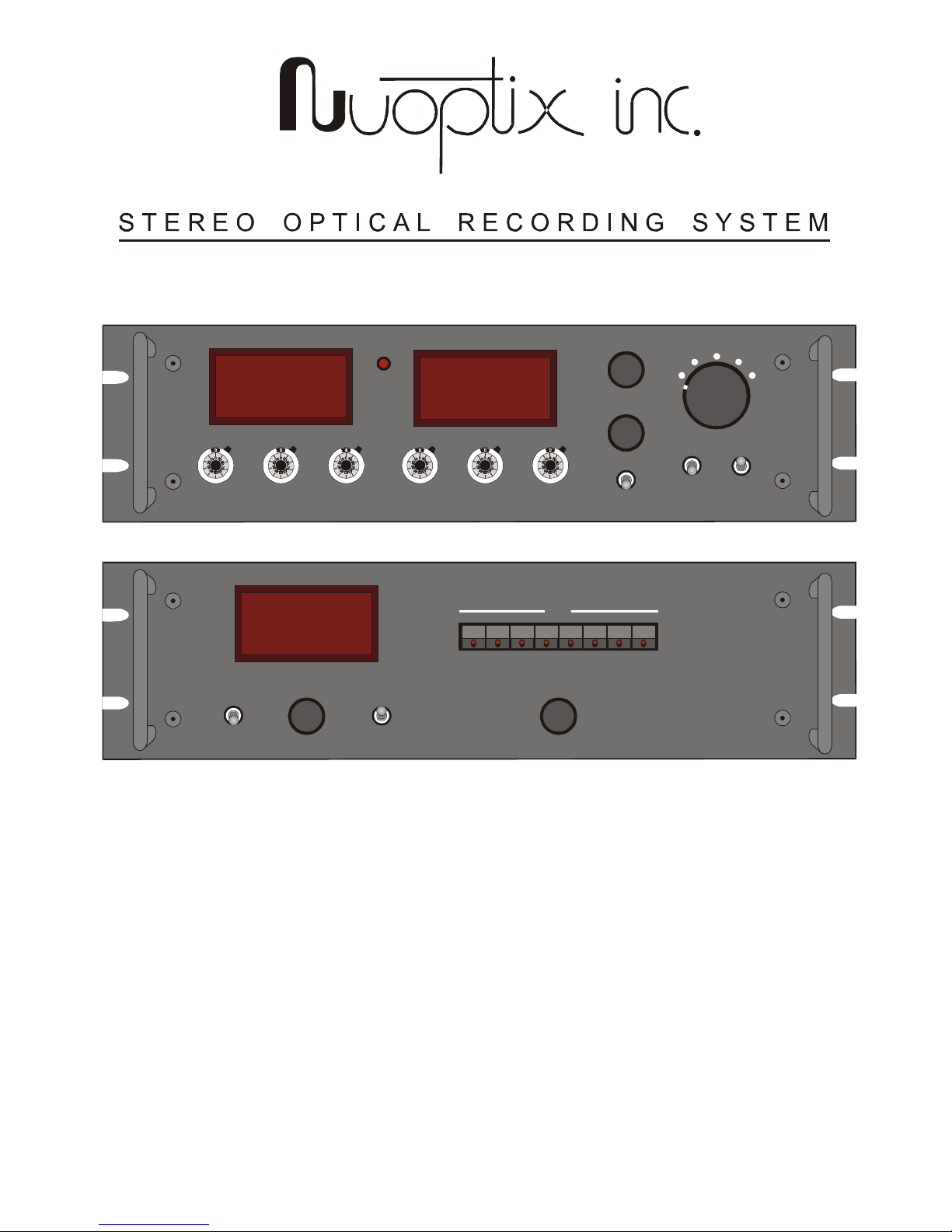

AUXILLARY OPTICAL SYSTEM (AOS)

Electrical Characteristics

Lamp Output: 12VDC at 4.25 to 8.50 amps

Di ital Meter: Displays lamp current in amps

Si nal Output: Minus infinity to +13dbm

Auto-controlled from SORS

Frequency Tolerence: ±0.005%

Output Frequencies: 400Hz Tone, 800 Hz Head Tone, 1kHz Tone

6kHz, 8kHz, 10kHz, 12kHz X-MODS

Pink Tone: 30 components 1/3 octave spacin

Equal amplitude

Pink Tone Freqs: 24,32,40,48,64,80,96,128,160,192,256,320,

384,512,640,768,1024,1280,1536,2048,

2560,3072,4096,5120,6144,8192,10240,

12288,16384,20480 Hertz

Power Output: ±15VDC at 1.5 amps

+5VDC at 0.5 amps

Power Requirements: 115 VAC or 230 VAC at 60Hz or 50 Hz

Power Consumption: Approximately 225 watts

Physical Characteristics:

Dimensions: 19 inches (482.6mm) wide

5.25 inches (133.3mm) tall

14.5 inches (368.3mm) deep

Wei ht: 26 lbs. 8 oz. (13.2 K )

ii