Pro N2Alarm nitrogen Analyzer

Nuvair Page 5 www.nuvair.com

2.0System Description

The Pro N2 Alarm nitrogen analyzer measures nitrogen (N2) levels in gases in the range of

0.0 to 100%. The Analyzer is designed to verify N2concentration in stored gas cylinders,

enclosed spaces and with compressors pumping nitrox. When used in breathing gas

applications, redundant Analyzers must be used for verification. In diving, for example, one

Analyzer must be used to monitor nitrogen during breathing gas production and a second

independent Analyzer must be used to verify the nitrogen content of the stored breathing gas

prior to diver use.

When using the Analyzer for diving applications with mixed gases other than air, you

must first obtain proper instruction from a certified diving instructor with a nationally

recognized training agency qualified in mixed gas diving. Improper use of this analyzer

may result in incorrect gas analysis which can lead to serious personal injury or death.

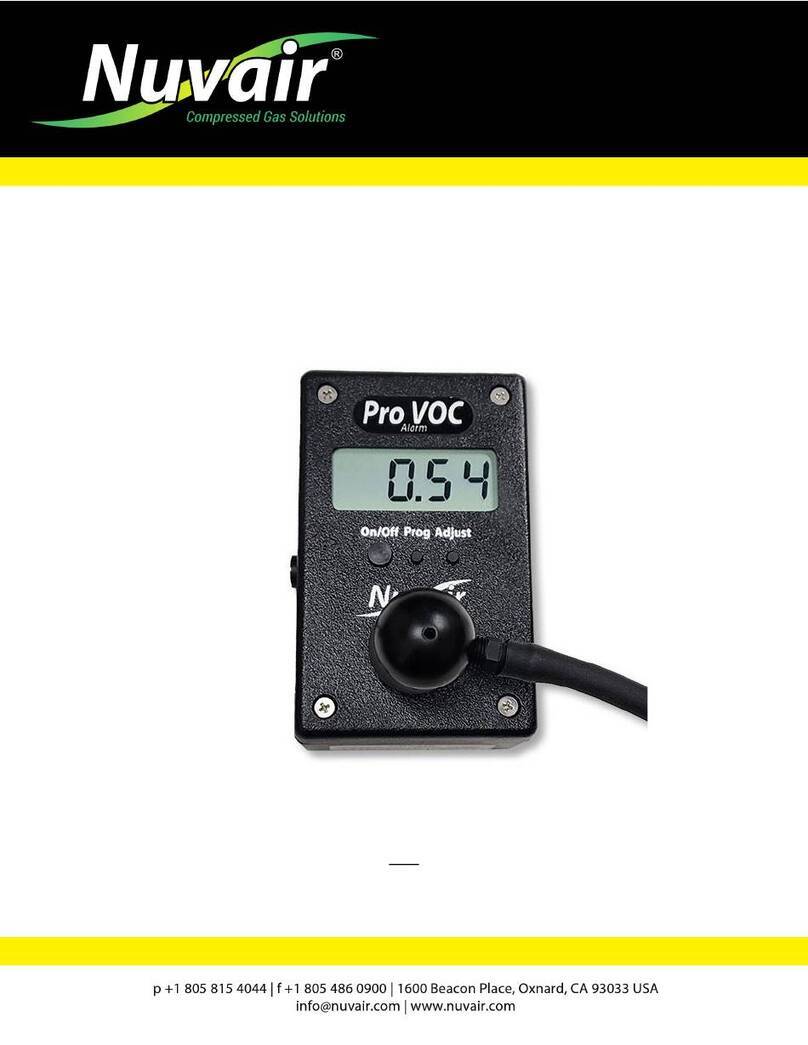

The Analyzer is battery powered and includes an

internally mounted Sensor with audible alarm. The

Water-Resistant Case includes a Digital Display and

controls that are environmentally sealed

The Analyzer uses a Flow Adapter Cap and Flexible

tubing to deliver sample gas to the Sensor.

Pressurized gases must be regulated to avoid

damage to the analyzer. Use of this Analyzer in a

hyperbaric chamber will void the owner’s warranty.

The Analyzer comes in a high impact storage case.

It is ready for use after calibration with an

appropriate certified calibration gas.

This analyzer is designed for use at atmospheric pressures only. It is not designed for

exposures in a hyperbaric chamber. Use of this analyzer in a hyperbaric chamber will

result in incorrect readings and may damage the unit.

Although the Analyzer is a rugged instrument, careless handling or abuse may result

in damage to the Analyzer resulting in inaccurate gas analysis. Inaccurate gas analysis

can lead to serious personal injury or death.

Breathing gas must always be analyzed by two separate Analyzers, with one used for

production and one used for analysis after production. Never depend on a single

Analyzer during both gas production and delivery. If the Analyzer readings do not

agree, both units must be recalibrated. Inaccurate gas analysis can lead to serious

personal injury or death.

Adapter Cap

Over Sensor

Face

Resistant