3

CGR-FX / OM 16-06 June 2016

I. INTENDED USE AND CONDITIONS OF USE

Intended use

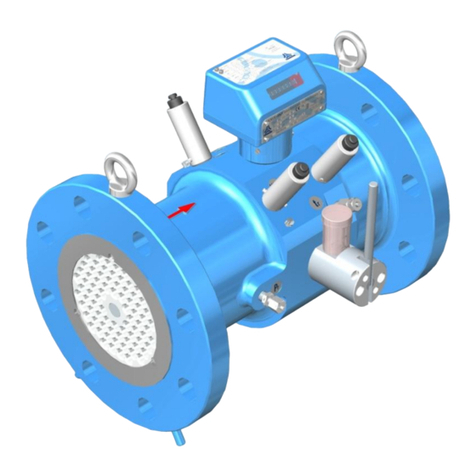

Rotary gas meters series CGR-FX are electromechanical pressure devices designed to

measure the volume of gas flowing through a system. The standard version meters may be

used in places with probable occurrence of explosive atmospheres formed as mixtures of

gases with air classified as explosion groups IIA and IIB (and group IIC for the special

versions). Table 1 lists the physical properties of the most common gases and gas mixtures

that may be measured with rotary gas meters.

CGR-FX Rotary Gas Meters enable the gas flows to be measured in any from among four

directions (horizontally –from left to right side, or from right to left side, and vertically –

from top to bottom or from bottom to top).

CGR-FX meters are manufactured with aluminum bodies and with cast iron bodies. Meters

with cast iron bodies may be manufactured as high temperature resistant version ( HTR ),

according to EN 12480:2002, Appendix C.

CGR-FX meters may be optionally equipped with a mechanical output. Mechanical output

may be used to drive peripheral devices. Rotational speed of the output shaft is the same as

the speed of the fastest drum in the index unit. Maximum permissible load torque on the

mechanical output shaft is 0.25 Nm.

As an option the CGR-FX Meters may be equipped with an internal by-pass that opens

automatically if there is a failure of rotors (seizure of rotors). This feature enables the gas

flow to pass by the measuring cartridge.

The rotary gas meters can be used both indoors in stabilized temperature conditions and

outdoors (open location).

Conditions for use

1. Compliance with Directive 2004/22/WE ( MID ) :

-certificate T10569 ( NMI )

- CE marking 1450 ( INiG - Oil and Gas Institute )

- high temperature resistant version (option) HTR pmax = 0.4 MPa

-ambient temperature range –25° C Ta + 70° C

-gas temperature range from –20° C to + 60° C

-storage temperature range from -30o C to + 70o C

-maximum working pressure pmax = 2.0 MPa

-mechanical environment class M2

-electromagnetic environment class E2

-metrological parameters Tables 2A, 2B.

-metrological accuracy class 1.0

-operational position HV,

2. Compliance with Directive 94/9/WE ( ATEX ) :

-certificate KDB 04ATEX034 rev. 5,

-CE marking 1453 ( Central Mining Institute,

Experimental Mine ”Barbara” ).

-operation conditions standard II 2G Ex ia IIB T5 Gb

special II 2G Ex ia IIC T5 Gb

- meter case index of protection IP66/IP67,

- ambient temperature –25° C t + 70° C