nVent.com/HOFFMAN

|

3

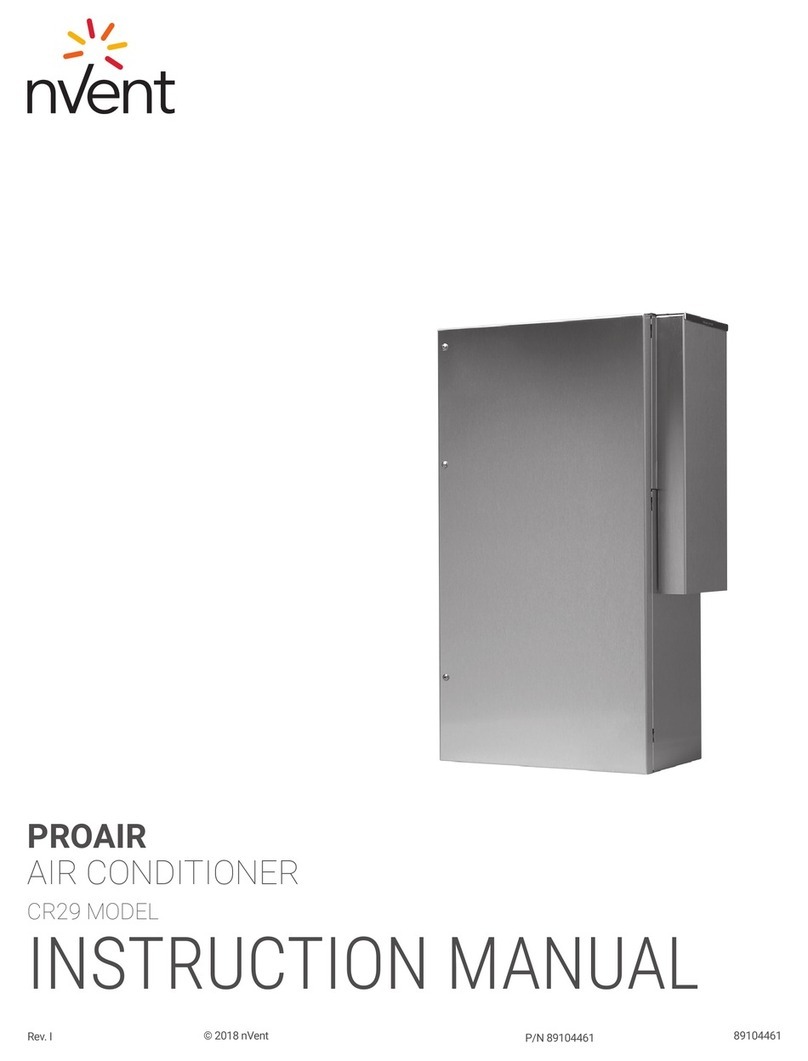

Note: Some of the information in this manual may not apply if a special unit was ordered. If additional drawings for a special unit are

necessary, they have been inserted. Contact nVent HOFFMAN if further information is required.

WARRANTY AND RETURN POLICY

https://HOFFMAN.nVent.com/en/HOFFMAN/warranty-information

TABLE OF CONTENTS

Warranty and return policy...........................................................................................................................................................................3

Receiving the air conditioner ......................................................................................................................................................................4

Handling and testing the air conditioner ......................................................................................................................................................4

Installation instructions...............................................................................................................................................................................5

Dimension drawing ............................................................................................................................................................................................... 5

Mounting cutout dimensions ............................................................................................................................................................................... 6

Wire diagram.......................................................................................................................................................................................................... 7

Schematics ...........................................................................................................................................................................................................8

Technical information .................................................................................................................................................................................9

Design data ............................................................................................................................................................................................................ 9

Washdown note ....................................................................................................................................................................................................9

Component list .....................................................................................................................................................................................................9

Smart controller .......................................................................................................................................................................................10

Principles of operation ..............................................................................................................................................................................10

Overview .............................................................................................................................................................................................................. 10

Energizing the controller .................................................................................................................................................................................... 10

Control status indication .................................................................................................................................................................................... 10

Displaying and changing program settings ....................................................................................................................................................... 13

To view or access the settings ................................................................................................................................................................. 13

Heat/cool operating parameters ....................................................................................................................................................................... 13

Alarm parameters ............................................................................................................................................................................................... 13

Displaying temperature data on screen ............................................................................................................................................................ 15

Compressor restart time delay .......................................................................................................................................................................... 15

Alarm output contact ......................................................................................................................................................................................... 15

Alarm input connection ...................................................................................................................................................................................... 15

Primary-secondary (PS) mode ........................................................................................................................................................................... 16

Connecting units together in primary/secondary mode .................................................................................................................................. 16

Connecting units together in lead/lag mode .................................................................................................................................................... 17

Air conditioner unit remote communication features ...................................................................................................................................... 18

USB communication ................................................................................................................................................................................. 18

Ethernet communication ........................................................................................................................................................................... 18

Using nVent HOFFMAN PC interface tool ......................................................................................................................................................... 19

USB communication mode ....................................................................................................................................................................... 19

USB communication mode .......................................................................................................................................................................20

Ethernet communication mode ................................................................................................................................................................ 21

Remote access control pin-out ..........................................................................................................................................................................22

Maintenance .............................................................................................................................................................................................23

Inlet air filter ........................................................................................................................................................................................................23

How to remove, clean or install a new inlet air filter ........................................................................................................................................23

Refrigerant loss ...................................................................................................................................................................................................24

Preventive Maintenance/Inspection ..................................................................................................................................................................25

Trouble shooting .......................................................................................................................................................................................26

F-GAS information.....................................................................................................................................................................................28