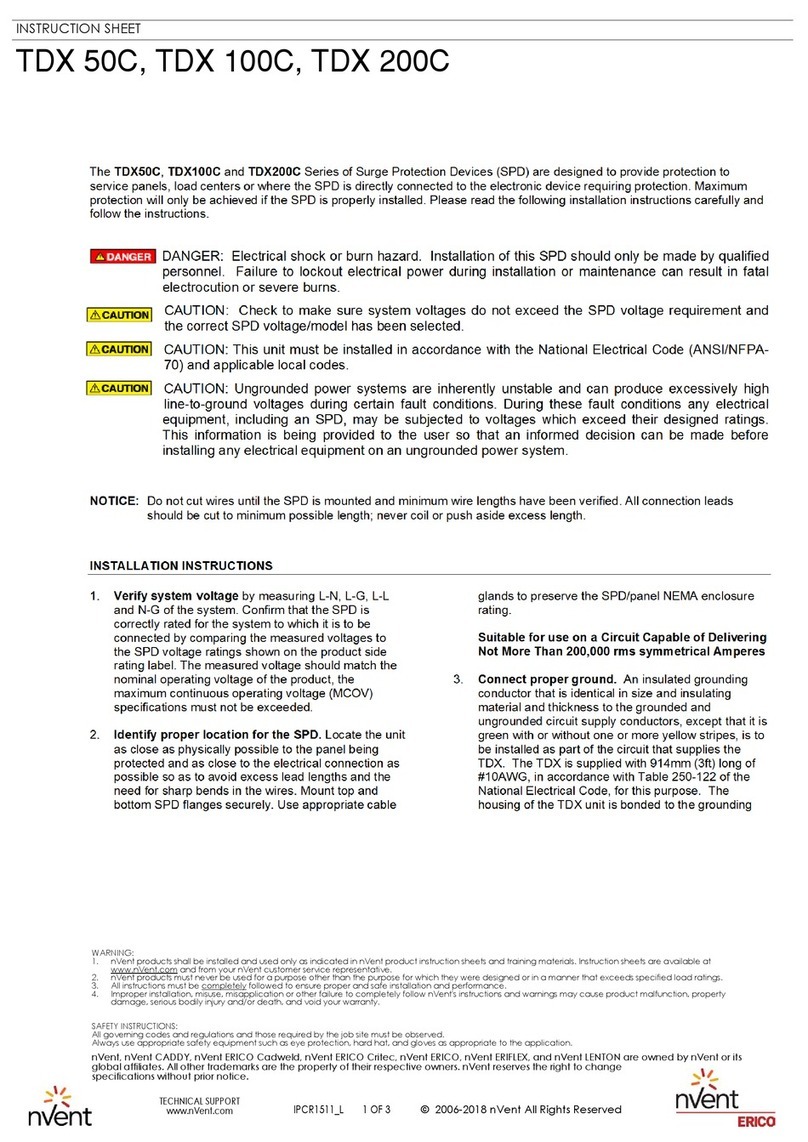

Circuit Breaker Connected

When connected on load side of main disconnect, we suggest connecting via a 60-125A circuit breaker. The circuit

breaker is the intended disconnect switch and provides short circuit protection to the connecting conductors. These

SPDs have internal overload protection elements within the product. These SPDs have demonstrated 200kA Short

Circuit Current Ratings (SCCRs).

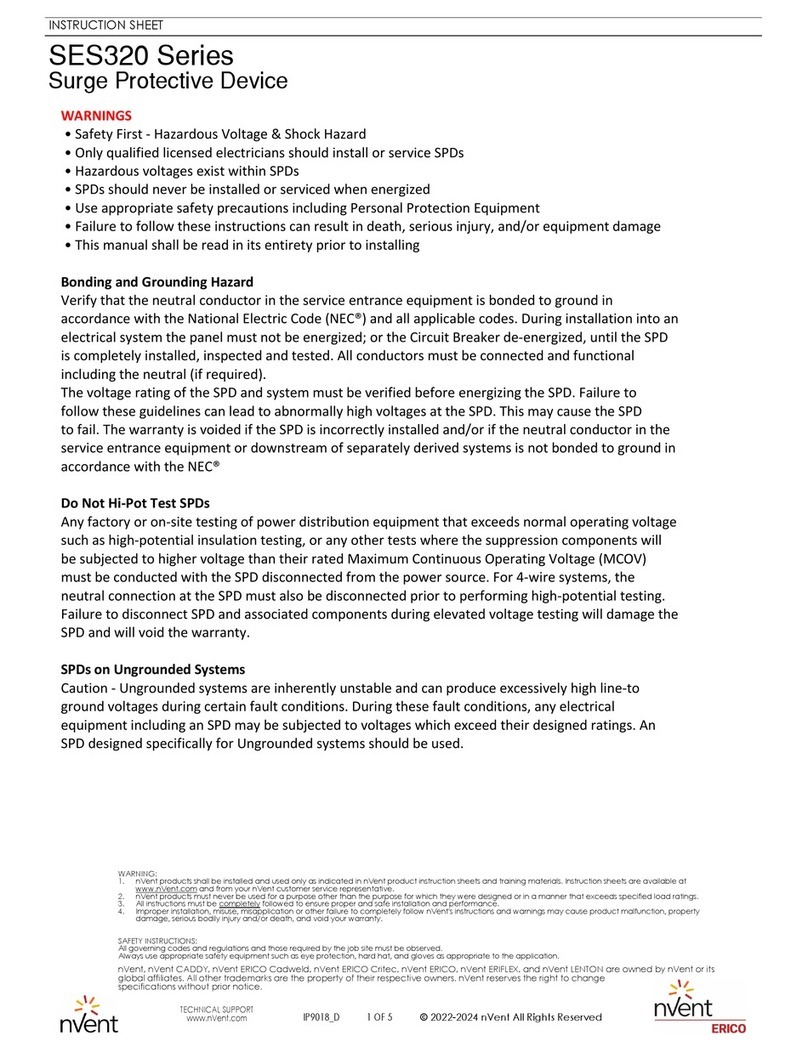

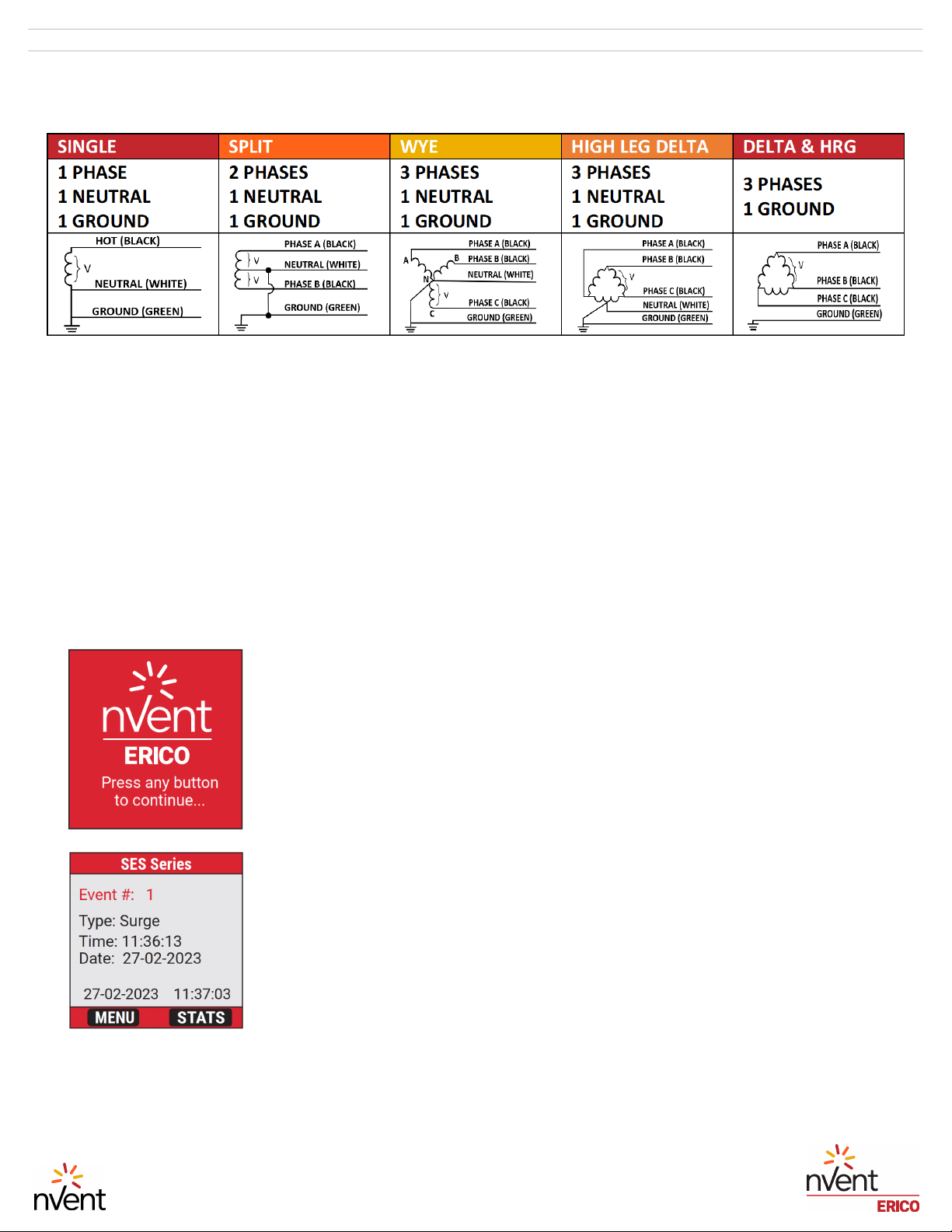

System Grounding

An equipment grounding conductor must be used on all electrical circuits connected to the SPD. For the best

performance, use a single point ground system where the service entrance grounding electrode system is connected

to and bonded to all other available electrodes, building steel, metal water pipes, driven rods, etc. (for reference see:

IEEE Std 142-2007). For sensitive electronics and computer systems, we recommend that the ground impedance

measurement be as low as possible. When metallic raceway is used as an additional grounding conductor, an

insulated grounding conductor should be run inside the raceway. Adequate electrical continuity must be maintained

at all raceway connections. A separate isolated ground for the SPD is NOT recommended. Proper equipment

connections to grounding system and ground grid continuity should be verified via inspections and testing on a

regular basis as part of a comprehensive electrical maintenance program. On 4-Wire Power Systems, neutral to

ground bonding (Main Bonding Jumper) must be installed per the NEC®. Failure to do so WILL damage SPDs.

UL 1283 required language concerning the installation of EMI Filters

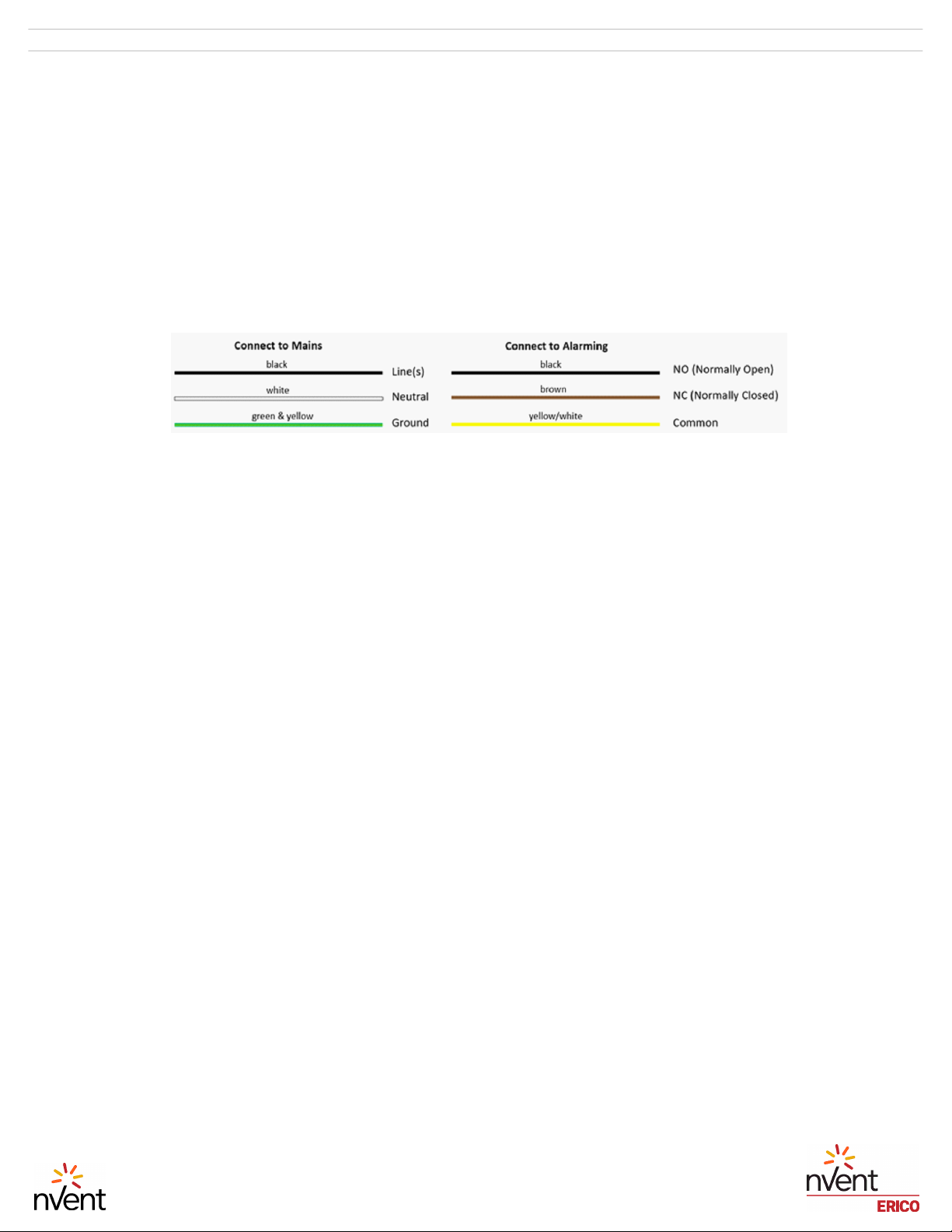

a) An insulated grounding conductor that is identical in size and insulation material and thickness to the

grounded and ungrounded circuit supply conductors, except that it is green with or without one or more

yellow stripes, is to be installed as part of the circuit that supplies the filter. Reference should be made to

Table 250-122 of the National Electrical Code regarding the appropriate size of the grounding conductor.

b) The grounding conductor mentioned in item a is to be grounded to earth at the service equipment or other

acceptable building earth ground such as the building frame in the case of a high-rise steelframe structure.

c) Any attachment-plug receptacles in the vicinity of the filter are to be of a grounding type, and the grounding

conductors serving these receptacles are to be connected to earth ground at the service equipment or other

acceptable building earth ground such as the building frame in the case of a high-rise steel-frame structure.

d) Pressure terminal or pressure splicing connectors and soldering lugs used in the installation of the filter shall

be identified as being suitable for the material of the conductors. Conductors of dissimilar metals shall not be

intermixed in a terminal or splicing connector where physical contact occurs between dissimilar conductors

unless the device is identified for the purpose and conditions of use.

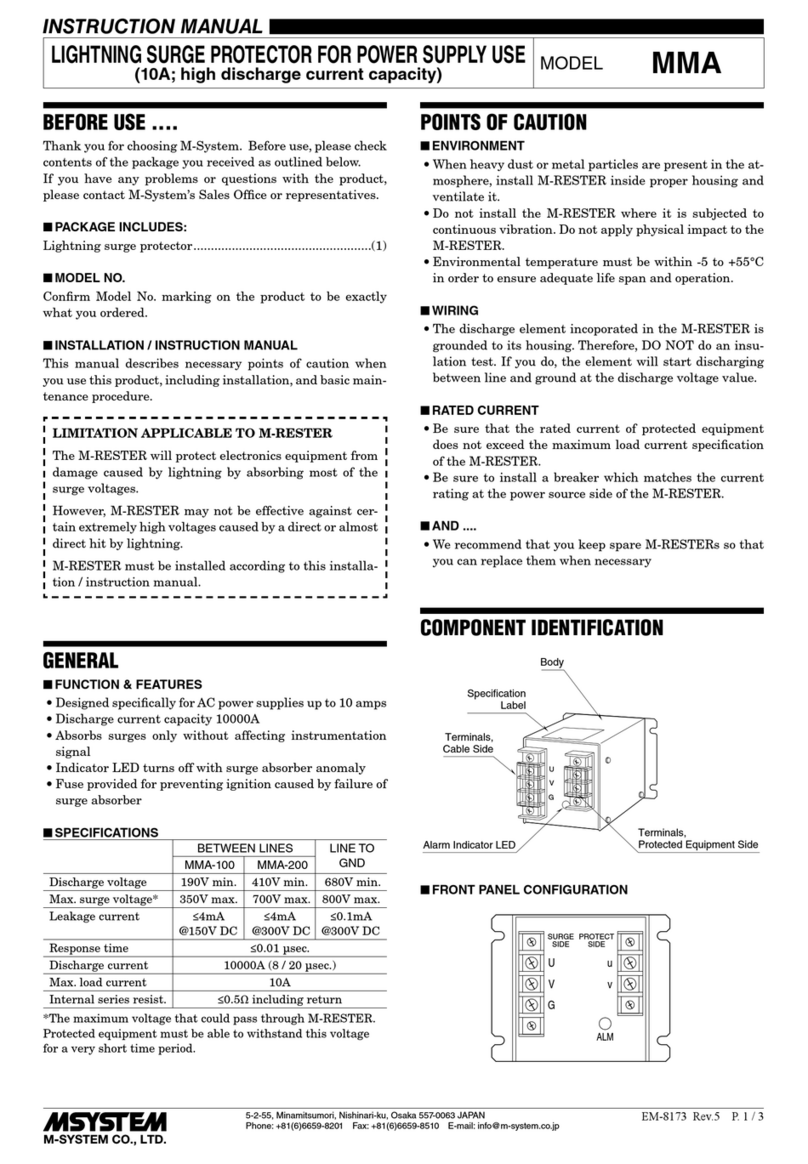

Retro-fit Into Existing Panel with No Available Breaker Positions

Follow all applicable Codes:

Consider consolidating loads in a manner that might free breaker positions.

A ten foot tap rule in NEC® 240.21(B)(1) allows you to tap the bus as long as the tap conductors are rated at least

10% of the ampacity of the panel. In the case where the ampacity of the panel is larger the wires of the SPD,

consider tapping the bus per NEC® 240.21(B)(1) and running appropriate size conductors to a safety switch fused to

60-125A. Mount the SPD immediately adjacent to the safety switch.

TECHNICAL SUPPORT

www.nVent.com

89230412_A

3 OF 10

INSTRUCTION SHEET

nVent, nVent CADDY, nVent ERICO Cadweld, nVent ERICO Critec, nVent ERICO, nVent ERIFLEX, and nVent LENTON are owned by

nVent or its global affiliates. All other trademarks arethe property of their respective owners. nVent reserves the right to change

specifications without prior notice.

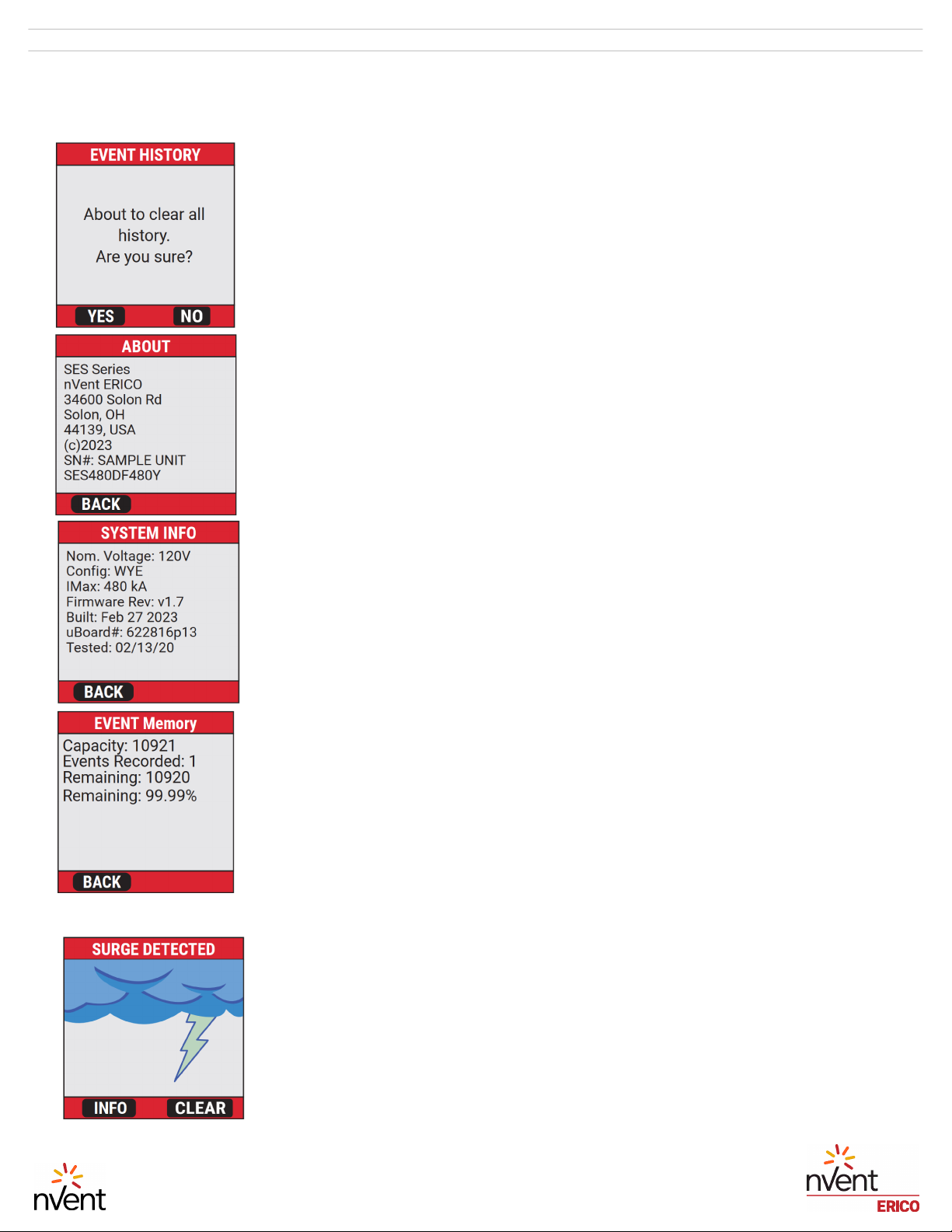

SES360 & SES480 Series

Surge Protection Device

© 2023 nVent All Rights Reserved

Downloaded by: - 2023-11-01 10:45