TSI software configurations

KE15Z Touch Sensing Interface, User's Guide, Rev. 0, 12/2016

NXP Semiconductors 7

the parastic capacitance.

•Rs: Configurable, parameter of analog front end which can be configured by

M_SEN_RES<3:0>.

•

: Configurable, the current multiplier

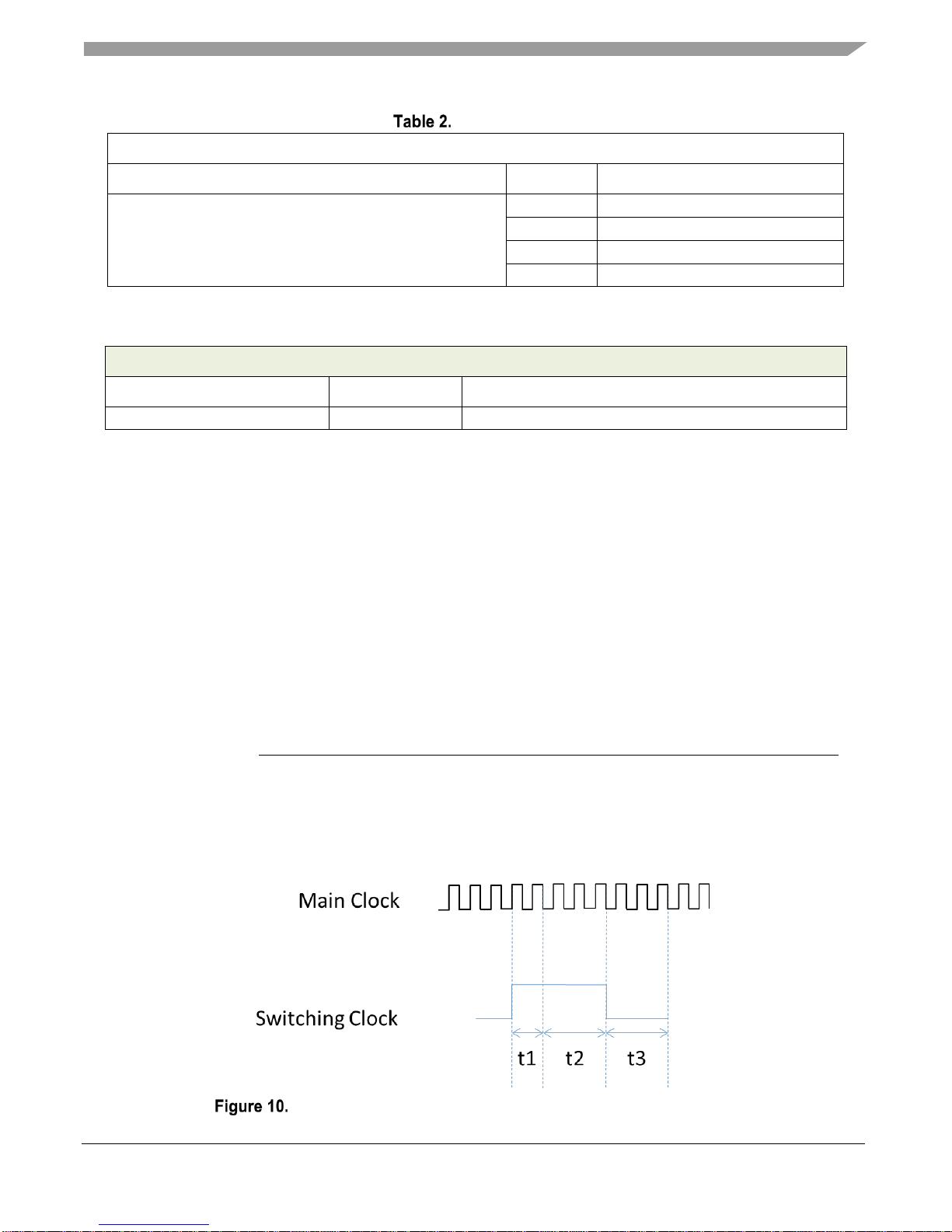

•T3: Configurable, SSC output low period

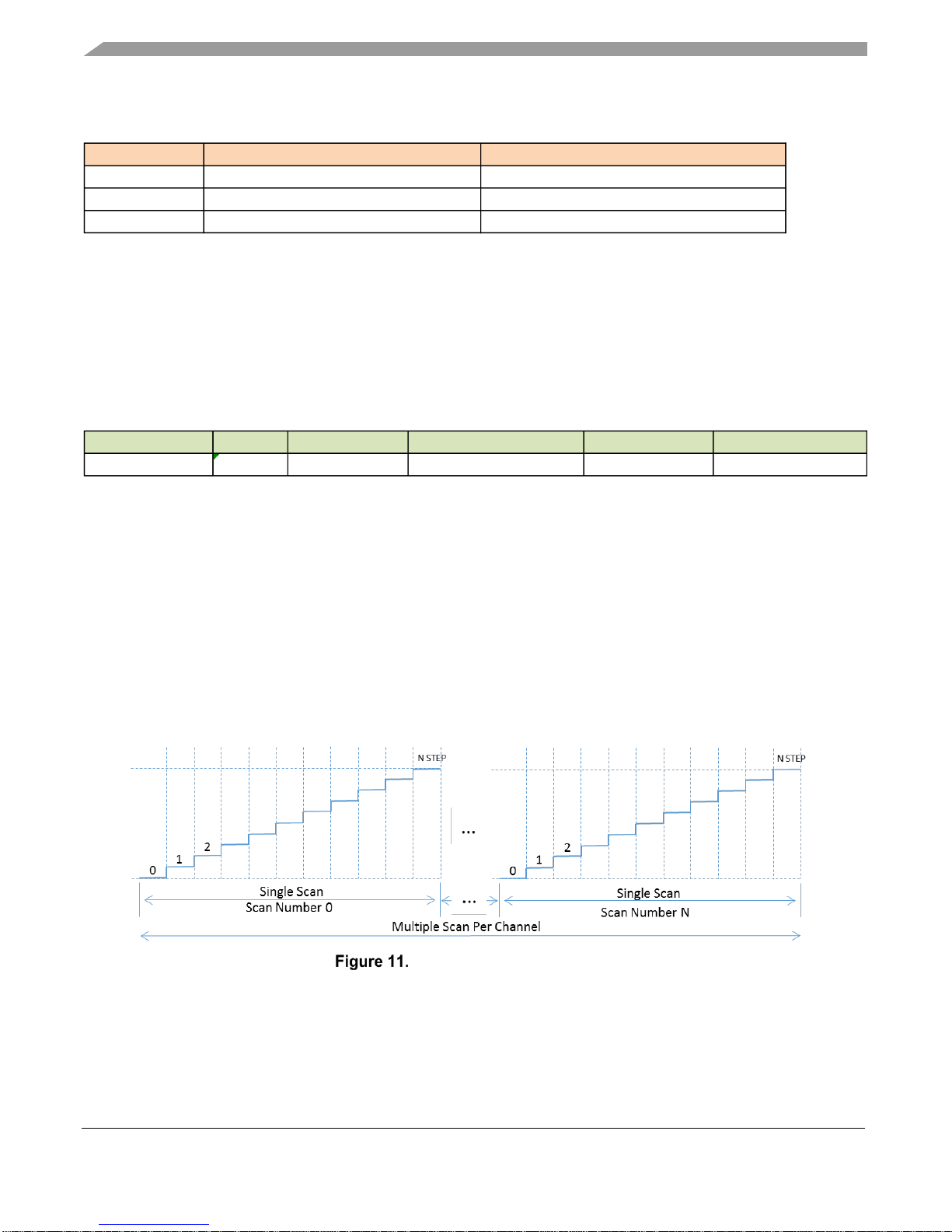

The basic formula of the scan time is listed below, Tnstep is the time costed of TSI single scan:

•Fsw: Configurable, the switching clock frequency.

For example, Ci=90pF, vp-vm=1v, Rs=10k, dV=100mV, M_L/M_R=4, Tsw/T3=4, so it will cost 160us

single scan time for TSI mutual mode.

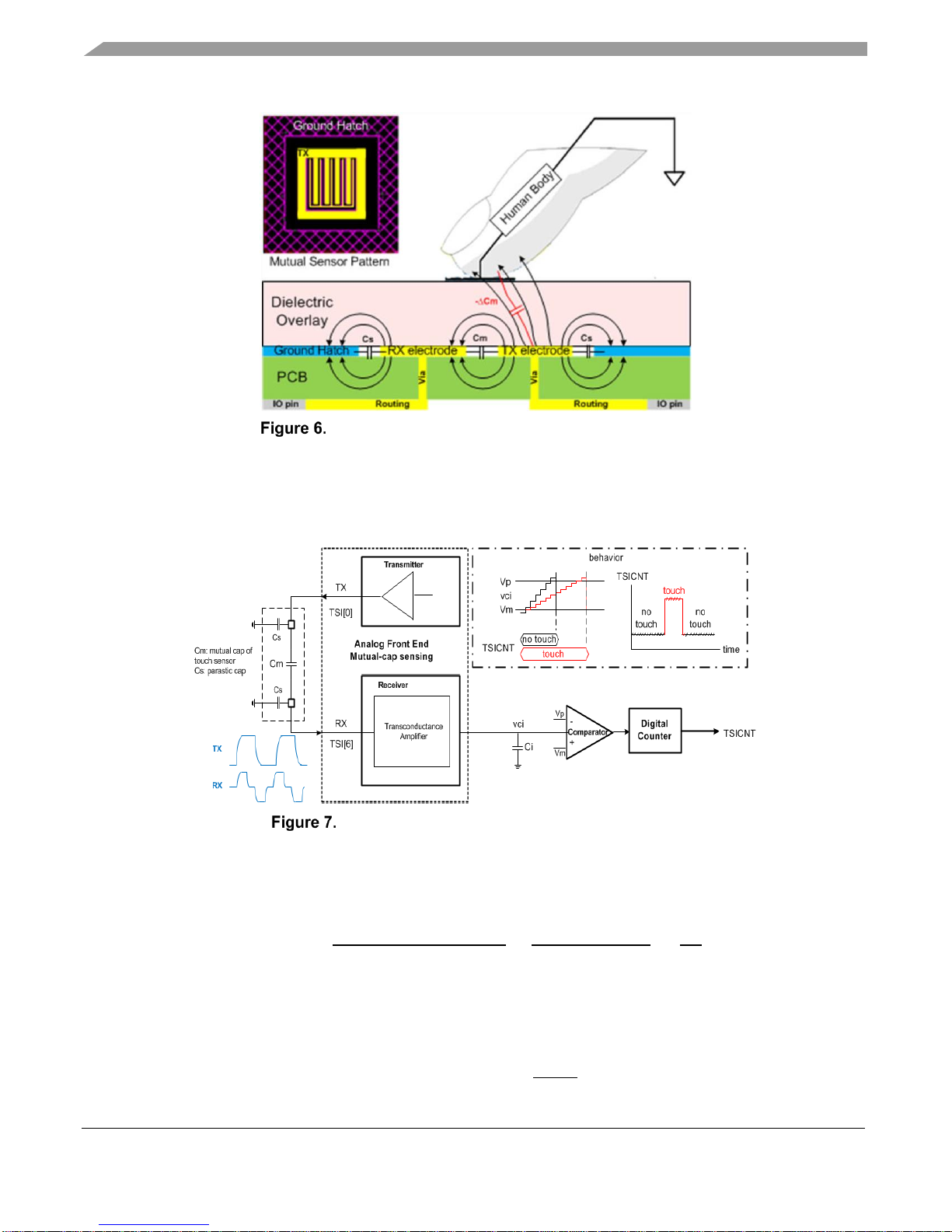

2.2.2. Sensitivity boost

If the mutual touch sensor intrinsic sensitivity is limited due to parasitic, sensitivity boost feature can be

activated by setting M_SEN_BOOST<4:0>. The basis average charge current will be subtracted by

boost current which enlarge the signal current.

In one typical case, ΔV=100mV, Rs=10k, Vp-Vm=1V, Fsw=1MHz, Ci=90pF,

M_PMIRRORL=16, M_PMIRRORR= M_NMIRROR= 2; Dec=8, Order=2.

NSTEP=72; TSICNT=4608;

Note: Keep M_PMIRRORR and M_NMIRROR the same.

3.TSI software configurations

3.1. Self-capacitive mode configurations

The software configurations for the self-capacitive mode include:

clock generation

scan time

comparator

sensitivity boost

Attached below is an example of the configurations for the self-capacitive mode.