Network Electronics Flashlink DLY-AES User manual

network-electronics.com

Dual AES Audio Delay

Rev. 3

Flashlink User Manual

DLY-AES

DLY-AES Rev.3

Network Electronics ASA

Thorøya

P.O. Box 1020

Sandefjord, Norway

Phone: +47 33 48 99 99

Fax: +47 33 48 99 98

E-mail: [email protected]

www.network-electronics.com

Service Phone: +47 90 60 99 99

Revision history

Current revision of this document is the uppermost in the table below.

Revision Replaces Date Change description

3 2 2007-10-26 New front page and removed old logo.

2 1 2007-10-08 Added Materials Declaration and EFUP

1 0 13/10/05 Corrected chapter 4.2 and 4.3.

0 A 01/03/05 First official release.

A - Preliminary version.

2

DLY-AES Rev.3

Contents

Revision history............................................................................... 2

1 Product overview......................................................................... 4

2 Specifications .............................................................................. 5

2.1 Measurement conditions .............................................................................5

2.2 General........................................................................................................5

2.3 AES inputs ...................................................................................................5

2.4 Reference input ...........................................................................................5

2.5 Outputs.......................................................................................................5

2.6 Delay...........................................................................................................5

2.7 VUC bit handling.........................................................................................5

2.8 Sample rate converter performance.............................................................6

2.9 GPI connections ..........................................................................................6

3 Detailed description..................................................................... 7

3.1 Delay value..................................................................................................7

3.2 Reference sample frequency ........................................................................7

3.3 Limitations...................................................................................................7

4 Configuration .............................................................................. 8

4.1 Rotary switches............................................................................................8

4.2 DIP switches ................................................................................................8

4.3 GYDA settings .............................................................................................9

4.4 Examples .....................................................................................................9

5 Connector module .................................................................... 10

5.1 Mounting the connector module ..............................................................10

5.2 Audio connections.....................................................................................11

6 Module status............................................................................ 12

6.1 GPI Alarm – Module status outputs............................................................12

6.2 Front panel – Status monitoring ................................................................13

General environmental requirements for flashlink®equipment ...... 14

Certificate of Conformity .............................................................. 15

Product Warranty ......................................................................... 16

Materials declaration and recycling information............................ 17

Materials declaration .................................................................... 17

Environmentally-friendly use period.............................................. 17

Recycling information................................................................... 18

3

DLY-AES Rev.3

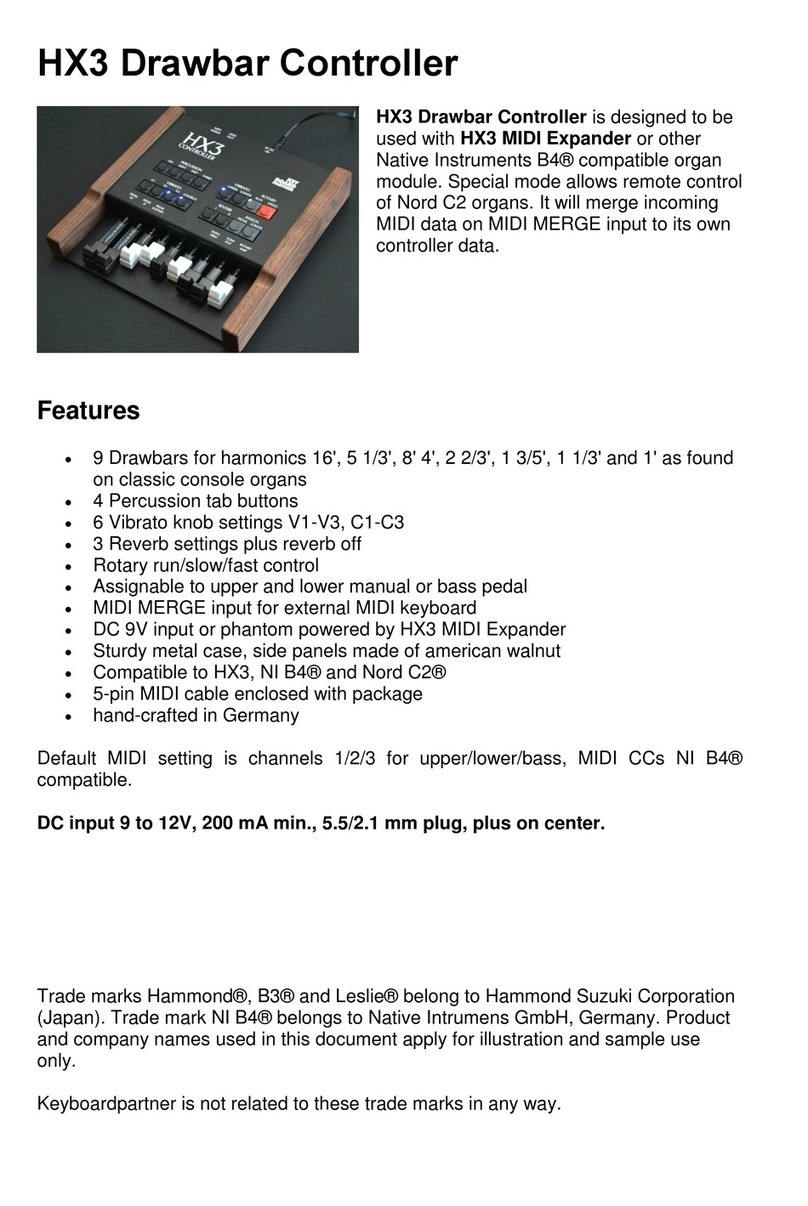

1Product overview

The DLY-AES is a digital audio delay module in the Network Electronics

flashlink®range.

The module has two stereo delay lines for digital audio which may be

controlled separately or together.

A tracking delay function may be controlled with an external pulse signal

supplied by a frame synchroniser such as the FRS-SDI or the DAC-SDI.

Each delay line has four different constant delay presets, one of which may be

added to the tracking delay. The preset is controlled either by Gyda or by GPI.

Delay changes are performed noiselessly.

All four outputs may be used with Delay line 1.

Maximum delay is 10.6s @ 48 kHz

Microcontroller Remote

Control

AES 2 (2)

AES 2 (1)

AES 1 (2)

AES 1 (1)

Black Burst

Reference Input

Delay Control Input

AES 2

AES 1

Tracking Input

AES-11

GPI x 2

Clock Control PLD

SRC

SRC

Sync. Sep.

Delay Control

d

Delay M

U

X

Delay

Tracking Control

Dip Sw. Setting

d

Figure 1: DLY-AES Dual AES Audio Delay.

4

DLY-AES Rev.3

2Specifications

2.1 Measurement conditions

Audio sampling rate: 48 kHz.

Ambient temperature: 25ºC.

2.2 General

Power: +5V DC approx. 0.3A 1.5W.

Control: DIP switches, Gyda system controller.

Monitoring: Front panel LEDs and Gyda system controller.

2.3 AES inputs

Number of inputs: 2 (AES3-1995).

Connector: Cannon D-sub 25 pin female.

Sample rate converter

word-length:

24 bits.

Sample rates: Any between 1/3 and 3 times the reference sample rate.

2.4 Reference input

Format: AES11 (AES-3-ID) or analogue video.

Connector: BNC.

Reference Sample rate

from video:

48 kHz.

Sample rates from AES11: 48, 44.1, 32 kHz. Other rates >32 kHz will be accepted but

the delay calculations may be incorrect.

2.5 Outputs

Number of outputs: 4 (AES3-1995).

Connector: Cannon D-sub 25 pin female.

Usage: Either dual outputs from delay lines 1 & 2 or quad outputs

from delay line 1.

2.6 Delay

Minimum delay: Dependant on input and reference sample rates

92 samples at 48kHz input and reference.

Maximum delay: 0x80000 samples, 230ms reserved for tracking delay.

Maximum fixed delay

@ 48 kHz:

@ 44.1 kHz:

@ 32 kHz:

10.6s

11.6s

16.1s

2.7 VUC bit handling

Channel status and (in)Validity bits are transported but there is a small latency. Output

channel status is modified to reflect reference sample frequency.

5

DLY-AES Rev.3

User bits are not transported.

V bits are not tested for every received sample. Singular occurrences of V bits may be

missed but long runs will be transported.

2.8 Sample rate converter performance

Digital word length: 24 bits.

THD+N @ -1 dB FS: -107 dB worst case.

Dynamic range:1: 120 dB (A) worst case.

2.9 GPI connections

Input levels: 5V TTL.

Internal pull-up resistor: 4.7 kΩ.

Output type: NPN transistor open collector.

Maximum voltage: 45V.

Maximum current: 500mA.

1|THD+N @ -60 dBFS A-weighted| + 60

6

DLY-AES Rev.3

3Detailed description

The DLY-AES card is a compact dual stereo audio delay line in the Conquer

module range. It has two AES3 digital audio inputs and each output is

duplicated giving four AES3 outputs. The card has two audio delay lines which

may be controlled by the switches on the card, by the GPI preset lines or by

the Gyda system controller.

It may be used as a tracking audio delay used with frame synchronisers such

as the FRS-SDI module or the DAC-SDI video converter with built-in

synchroniser.

3.1 Delay value

The delay time in each of the two delay lines will be sum of a static delay

(which may also be zero) and the tracking delay, if required.

The tracking delay time is derived from a pulse signal which is generated by

video frame synchronisers and encoders. This signal must be connected to the

RJ45 connector on the backplane. The tracking value is common for both

delay lines.

Delay changes will be performed without audible artefacts by choosing

switching points close to zero.

The static delay will be one of four presets which may be pre-programmed

into the card. The active preset may only be switched with the GPI signals.

Preset 1 is used when the GPI signals are not used. Gyda may be used to

program different values into the presets for delay line 1 and delay line 2. So,

preset 2 could be 100ms for delay line 1 and 200ms for delay line 2. This

allows switching of presets to account for different processing equipment

used. The only way to display the value of the four presets is with Gyda or

with RS422 commands.

The displayed total delay value shown by Gyda will always be the actual delay

through the module.

3.2 Reference sample frequency

The card uses a signal as a reference sample frequency for both delay lines.

The reference signal should not be switched or changed during use. The

reference may be analogue video or an AES signal applied to the reference

input. The AES1 input signal is used as the frequency reference if no signal is

present on the reference input. The reference signal is assumed to have one of

the normal sample frequencies and will use the closest number if an odd

sample frequency is used.

The card uses sample rate converters so that the programmed delay time

remains a constant number of samples for a given time. This also allows

sample rate correction (pitching) in other equipment.

3.3 Limitations

The output signals will be disrupted if the reference signal disappears or

changes.

User bits are not transported.

Only static channel status information will be correctly transported.

Singular asserted V bits may not be detected.

7

DLY-AES Rev.3

4Configuration

The configuration of the card may be performed with switches on the card or

from the Gyda system controller.

Each delay line has four delay presets. The static delay in each delay line may

be switched between presets. The first preset may be programmed with the

rotary switches on the front of the card.

Two pins on the GPI connector may be used to switch between the four delay

presets. The two pins are inverse binary coded so that preset one is when both

inputs are high and preset 4 is when both pins are pulled low.

4.1 Rotary switches

The rotary switches are only used when DIP switch 1 is on, i.e. the card is in

manual mode.

The four rotary switches program the delay value of preset 1.

The four switches correspond to the decimal digits of milliseconds. The lowest

switch is 1-9 ms, the next 10-20 ms, the next 100-200ms and the next 1-9 s.

From this is may be deduced that the maximum preset value will be 9,999 ms

or almost 10s.

4.2 DIP switches

Ten DIP switches control the most important functions of the card.

The first DIP switch sets the mode of the module. The other DIP switches are

only used if the first switch is in the 'ON' position.

Static delay is common for delay line 1 and delay line 2 in manual mode.

DIP switch configuration must be set according to the table below:

Switch # Function Factory default

1 Manual mode On

2 Include static delay on Delay line 1 (Rotary switches) On

3 Include dynamic delay on Delay line 1 On

4 Include static delay on Delay line 2 (Rotary switches) On

5 Include dynamic delay on Delay line 2 On

6 Route all outputs from Delay line 1 Off

7 Unused / reserved Off

8 Unused / reserved Off

9 Unused / reserved Off

10 Card operational mode run/!program On

All DIP switches are off when pointing towards the release handle.

Note!

Switch 10 must always be in the “ON” position.

8

DLY-AES Rev.3

4.3 GYDA settings

Gyda may be used to monitor the status of each of the input signals and set

up parameters in the cards. Switch 1 must be 'Off' if the parameters are to be

controlled by Gyda.

Four different static delays for each delay line may be programmed.

4.4 Examples

1) Manual mode, AES1 static delay, AES2 tracking delay

DIP switches from 1-10: 1,1,0,0,1,0,0,0,0,1 (1 is on, 0 is off)

Rotary switches top to bottom: 4,5,6,1

Tracking signal connected.

GPI inputs not connected.

=

Outputs AES1A and 1B are AES1 signal delayed by 4.561 s.

Outputs AES2A and 2B are AES2 signal delayed by the tracking delay value.

2) Manual mode, AES1 tracking + static delay, AES2 tracking delay

DIP switches from 1-10: 1,1,1,0,1,0,0,0,0,1 (1 is on, 0 is off)

Rotary switches top to bottom: 0,1,2,0

Tracking signal connected.

GPI inputs not connected.

=

Outputs AES1A and 1B are AES1 signal delayed by the tracking delay plus

120ms (3 video frame).

Outputs AES2A and 2B are AES2 signal delayed by the tracking delay value.

9

DLY-AES Rev.3

5Connector module

The DLY-AES has a dedicated connector module: DLY-AES-C1. This module is

mounted at the rear of the sub-rack. The module is shown in the figure below.

Figure 2: Connector module for DLY-AES.

The audio connector on the backplane is a 25 pin female d-sub connector

with UNC threads. The reference input and loop through connectors are

BNCs. The lower AUX BNC is not used. The RJ45 connector is used for alarms

and GPI selection of delay presets.

The tracking delay and preset GPI inputs are 5V TTL with internal 4.7kohm

pull-ups.

The Alarm outputs are active low open collector outputs.

The signal connections are shown in the figures on the next page.

5.1 Mounting the connector module

The details of how the connector module is mounted, is found in the user

manual for the sub-rack frame FR-2RU-10-2.

This manual is also available from our web site:

http://www.network-electronics.com/.

10

DLY-AES Rev.3

5.2 Audio connections

Figure 3: Audio connections on DLY-AES.

11

DLY-AES Rev.3

6Module status

The status of the module can be monitored in three ways.

1. GYDA System Controller (optional).

2. GPI at the rear of the sub-rack.

3. LED’s at the front of the sub-rack.

Of these three, the GPI and the LED’s are mounted on the module itself,

whereas the GYDA System Controller is a separate module giving detailed

information on the card status. The functions of the GPI and the LED’s are

described in sections 6.1 and 6.2. The GYDA controller is described in a

separate user manual.

6.1 GPI Alarm – Module status outputs

These outputs can be used for wiring up alarms for third party control

systems. The GPI outputs are open collector outputs, sinking to ground when

an alarm is triggered. The GPI connector is shown in figure below.

DLY-AES module GPI pinning:

Pin # Function

1 ALARM 1 (Card status).

2 ALARM 2 (AES 1 or AES 2 not detected).

3 Delay 0 (LSB static delay select).

4 Delay 1 (MSB static delay select).

5 Do not connect.

6 Do not connect.

7 Frame delay from FRS-SDI or DAC-SDI.

8 GND.

Figure 4: GPI connections on DLY-AES.

12

DLY-AES Rev.3

6.2 Front panel – Status monitoring

The status of the module can be easily monitored visually by the LED’s at the

front of the module. The LED’s are visible through the front panel as shown in

the figure below.

Figure 5: Front panel indicators for the DLY-AES.

The DLY-AES has 4 LED’s each showing a status corresponding to the GPI

pinning.

Diode \ State Red LED Green LED Orange LED No light

Card state Fatal internal

error.

Module power is

OK.

Not applicable. Module has no

power, or fuse is

blown.

Ref. state Not locked to

reference input.

Locked to

reference input.

Not applicable. Not applicable.

AES1 input

state

No signal input

Signal detected

and locked.

Not applicable. Not applicable.

AES2 input

state

No signal input

Signal detected

and locked.

Not applicable. Not applicable.

13

DLY-AES Rev.3

General environmental requirements for flashlink®equipment

1. The equipment will meet the guaranteed performance specification under the

following environmental conditions:

- Operating room temperature range: 0°C to 50°C

- Operating relative humidity range: < 90% (non-condensing)

2. The equipment will operate without damage under the following environmental

conditions:

- Temperature range: -10°C to 55°C

- Relative humidity range: < 95% (non-condensing)

3. Electromagnetic compatibility conditions:

- Emissions: EN 55103-1 (Directive 89/336/EEC)

- Immunity: EN 55103-2 (Directive 89/336/EEC)

14

DLY-AES Rev.3

Certificate of Conformity

Network Electronics ASA

N-3204 Sandefjord

Norway

Company Registration Number:

NO 976 584 201 MVA

Declares under sole responsibility that the product:

Product Name: DLY-AES

Product Description: Dual AES Audio Delay

To which this declaration relates are of Norwegian origin and are in conformity with

the following standards:

EN 55103-1: 1996 Generic Emissions Standard

EN 55103-2: 1996 Generic Immunity Standard

15

DLY-AES Rev.3

Product Warranty

The warranty terms and conditions for the product(s) covered by this manual follow the

General Sales Conditions by Network Electronics ASA. These conditions are available

on the company web site of Network Electronics ASA:

www.network-electronics.com

16

DLY-AES Rev.3

Materials declaration and recycling information

Materials declaration

For product sold into China after 1st March 2007, we comply with the “Administrative

Measure on the Control of Pollution by Electronic Information Products”. In the first

stage of this legislation, content of six hazardous materials has to be declared. The table

below shows the required information.

Toxic or hazardous substances and elements

組成名稱

Part Name

鉛

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr(VI))

多溴联苯

Polybrominated

biphenyls

(PBB)

多溴二苯醚

Polybrominated

diphenyl ethers

(PBDE)

DLY-AES X O O O O O

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous materials for

this part is below the limit requirement in SJ/T11363-2006.

X: Indicates that this toxic or hazardous substance contained in at least one of the homogeneous

materials used for this part is above the limit requirement in SJ/T11363-2006.

Environmentally-friendly use period

The manual must include a statement of the “environmentally friendly use period”.

This is defined as the period of normal use before any hazardous material is released to

the environment. The guidance on how the EFUP is to be calculated is not finalised at

the time of writing. See

http://www.aeanet.org/GovernmentAffairs/qfLeOpAaZXaMxqGjSFbEidSdPNtpT.pdf

for an unofficial translation of the draft guidance. For our own products, Network

Electronics has chosen to use the 50 year figure recommended in this draft regulation.

Network Electronics suggests the following statement on An “Environmentally Friendly

Use Period” (EFUP) setting out normal use:

EFUP is the time the product can be used in normal service life without leaking the hazardous materials.

We expect the normal use environment to be in an equipment room at controlled temperature range

(0ºC - 40ºC) with moderate humidity (< 90%, non-condensing) and clean air, not subject to vibration or

shock.

Further, a statement on any hazardous material content, for instance, for a product that

uses some tin/lead solders:

Where a product contains potentially hazardous materials, this is indicated on the product by the

appropriate symbol containing the EFUP. The hazardous material content is limited to lead (Pb) in some

solders. This is extremely stable in normal use and the EFUP is taken as 50 years, by comparison with the

EFUP given for Digital Exchange/Switching Platform in equipment in Appendix A of “General Rule of

Environment-Friendly Use Period of Electronic Information Products”. This is indicated by the product

marking:

50

17

DLY-AES Rev.3

It is assumed that while the product is in normal use, any batteries associated with real-time clocks or

battery-backed RAM will be replaced at the regular intervals.

The EFUP relates only to the environmental impact of the product in normal use, it does not imply

that the product will continue to be supported for 50 years.

Recycling information

Network Electronics provides assistance to customers and recyclers through our web

site http://www.network-electronics.com. Please contact Network Electronics’

Customer Support for assistance with recycling if this site does not show the

information you require.

Where it is not possible to return the product to Network Electronics or its agents for

recycling, the following general information may be of assistance:

Before attempting disassembly, ensure the product is completely disconnected from

power and signal connections.

All major parts are marked or labelled to show their material content.

Depending on the date of manufacture, this product may contain lead in solder.

Some circuit boards may contain battery-backed memory devices.

18

Table of contents

Popular Recording Equipment manuals by other brands

Sony

Sony STR-DA30ES - Fm Stereo/fm-am Receiver Service manual

VocoPro

VocoPro CDR-1000 PRO owner's manual

KYOWA

KYOWA PCD-300B Hardware instruction manual

Kaiser Baas

Kaiser Baas KBA03044 user guide

Wunder Audio

Wunder Audio Wunderbar Super D Operation manual

Dantel

Dantel D18-05547 Series Installation & operation manual