2

Thanks for buying this fog machine from O’FRESH. In order to help you correctly use it,

please read this user manual carefully before start the machine.

Safety Instruction

Please read this instruction carefully before any operation to avoid any danger and accident

The operator has to read and understand this instruction carefully

before any installation and operation. And has to follow the

install procedure, working procedure, safety precautions and

maintenance standard.

Please use the clean water. It's forbidden to use well water, river

water and any other dirty water. Once such dirty water is used,

the nozzles will be blocked, and pump life will be shorten or even

cause running problems.

Please check whether the wiring is exposed, whether any nut and

bolt is loose, and whether the each pipe is wrongly connected,

please adjust on time.

This product has self priming function, but there should don't

have air inside of the pump. Also, the water faucet connection

will be your first choice.

The spare parts of the fog machine, including water filter, pipe,

nozzle and so on, must use the original parts. Otherwise, it's very

easy to have water leakages, oil leakages and other problems.

When cleaning the spare parts and machine cover, the

non-corrosive safety solvent is required. All of the volatile,

flammable, explosive detergent is not allowed.

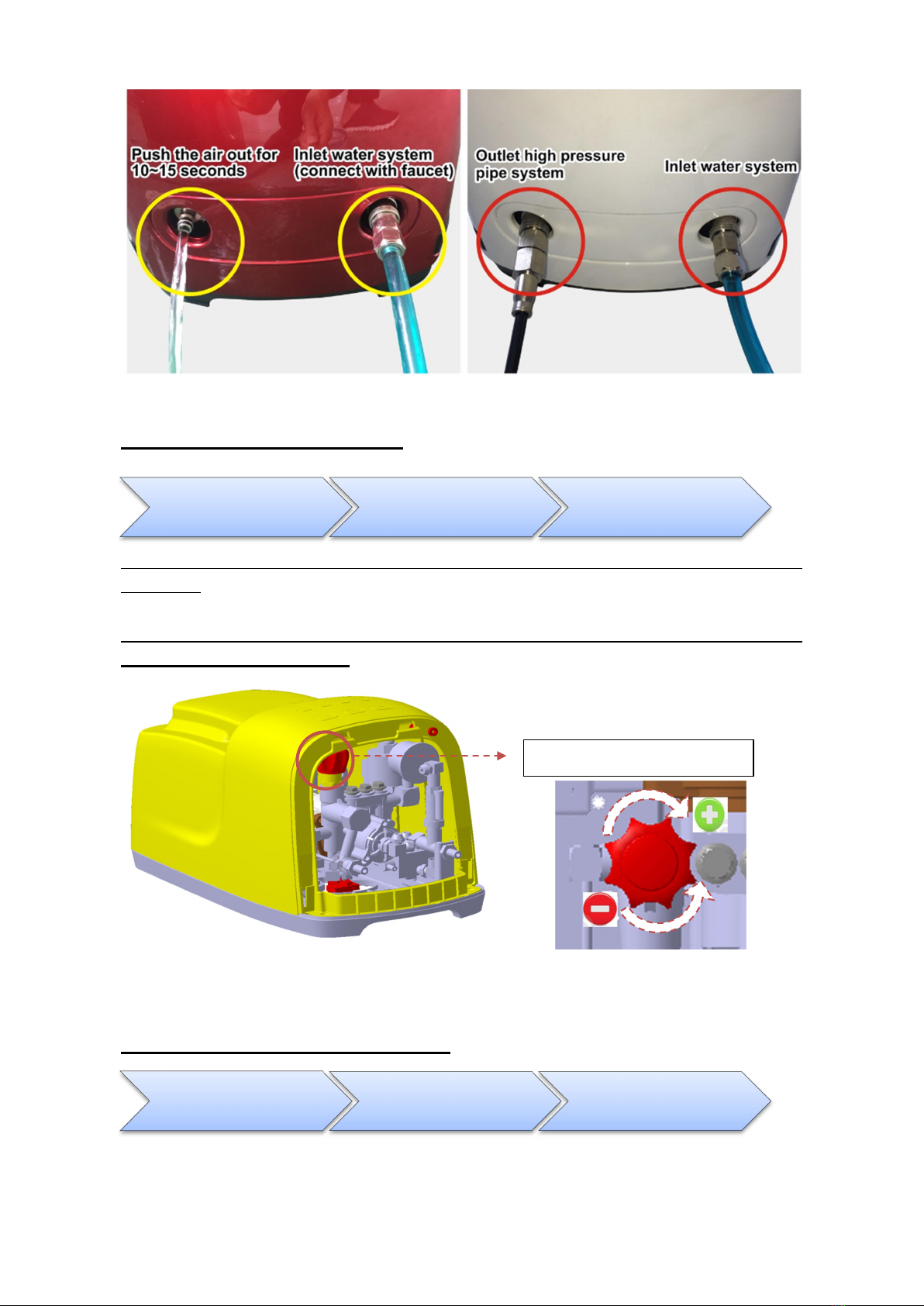

After running for some time, please check the pressure gage from

the machine(usually check per month), and make sure the

pressure is between 40bar to 70bar.

The water filter should be cleaned frequently to prevent the dirty

into the machine and nozzles and reduce product life.

The nozzles quantity and size should be in related range.

Otherwise, the pressure will not enough to supply the mist.

The nozzles are consumption goods, please change to new ones