V. Calibration

Calibration means conducting new configuration of the meter’s parameters with samples whose

standard moisture value has been already known. Calibration is used to increase measurement

categories or correct precisely the measurement error of existing categories.

The meter can be calibrated with up to 4 standard samples in the following method:

1. Prepare standard sample: adopt 105 standard drying oven method to prepare standard sample; to℃

make representative and accurate calibration, the maximum and minimum moisture value of standard

sample shall be at the two ends of the range of actually measured moisture values, with 3~6 percentage

points as the interval between different levels. If the range of measured moisture does not exceed 6

percentage points, only three standard samples (high, middle, low) or two standard samples (high, low)

are required (e.g., wheat, standard moisture values are arranged according to high, middle 1, middle 2,

low, i.e., 22%, 18%, 14%, 10% respectively);

2. Notices:

(1) The calibration must be performed in the order of low, middle, high moisture values;

(2) The meter shall not be shut down during calibration;

(3) The sensor shall be emptied prior to calibration.

3. Choose category code: press the “ ” or “ ” key to choose the code of the category to be calibrated△▽

(the previous calibration parameter under this code will be overlaid);

4. Enter into calibration status: press and hold the “确定”(OK) key (approx. 5~6s) and release it after

hearing the buzz. The character “Calibration” flickers at the bottom left corner of the LCD panel, and

is displayed, which means that the meter has entered into the calibration status and the

first standard sample shall be put in;

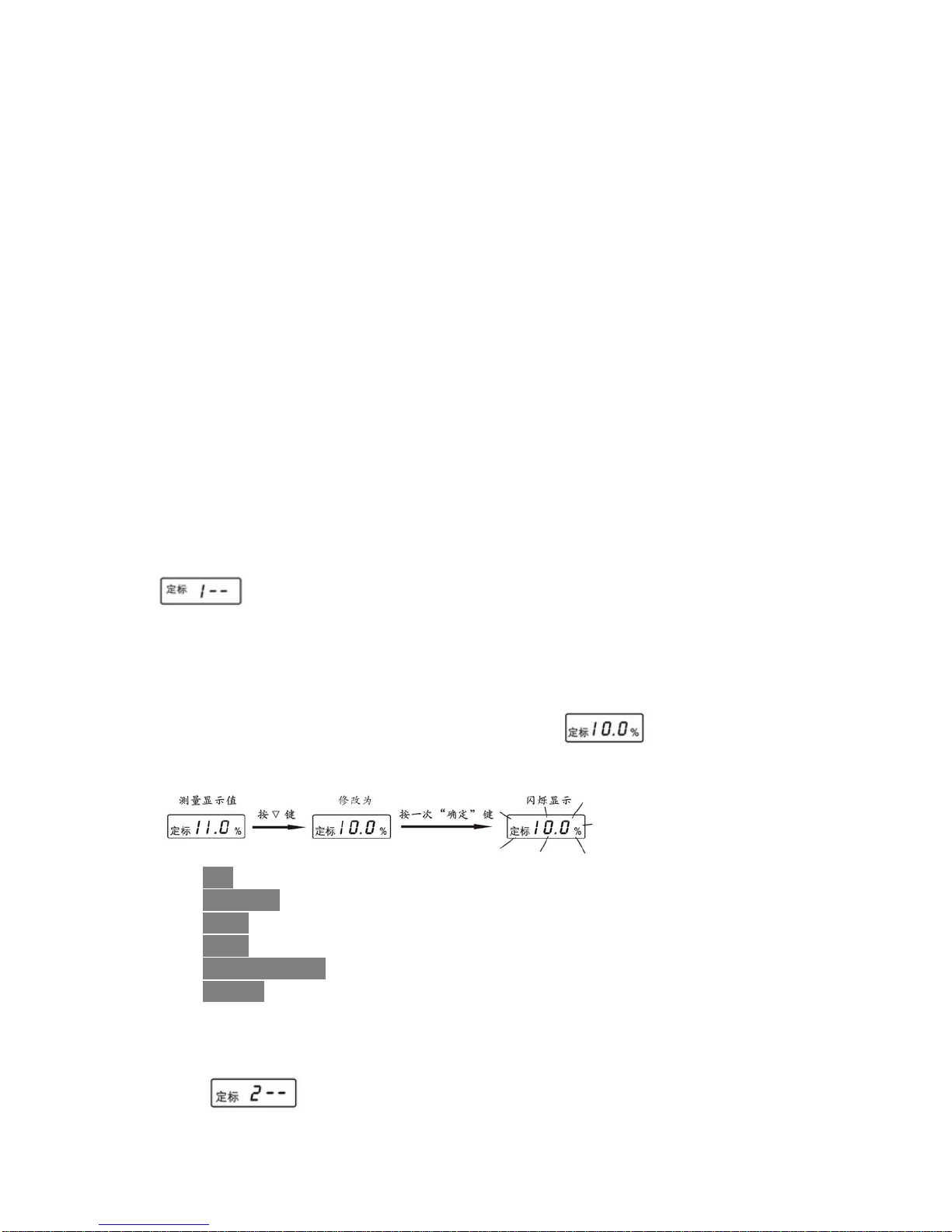

5. Calibrate low moisture: take the low-moisture standard sample and put it into the sensor through the

blanking cylinder. After the meter indicates the measured value (e.g., 11%), press the “ ” or “ ” key△▽

to modify the displayed value into the standard value (e.g., 10%), then press the “确定”(OK) key to

save the modification result. The meter displays the flickering , which means that the

one-point calibration is completed. See the following diagram:

Note 定标:Calibration

测量显示值:Displayed measurement value

按▽键:Press the “ ” key▽

修改为:Corrected as

按一次“确定”键:Press the “确定”(OK) key one time

闪烁显示:Flickering display

Note: the one-point calibration also acts as an error correction method. If the meter is shut down

at this time, it is equivalent to the completion of error correction.

6. Calibrate the second point: Empty the sensor of low-moisture standard sample and the meter will

display which means that the second standard sample shall be put in. Complete the

calibration of the second point in the same method as specified in the above step 5;