Document UT-MT-0872-EN Page 2 of 37

Edition 08/04/2020 LIMS INSTRUCTION MANUAL

INDEX

INDEX ................................................................................................................................................. 2

INDEX OF FIGURES ............................................................................................................................. 3

INDEX OF TABLES ............................................................................................................................... 3

1 GENERAL ......................................................................................................................... 5

2 CLASSIFICATION OF SIGNS ............................................................................................... 5

2.1 Type ................................................................................................................................ 5

2.2 Legend Sizes ................................................................................................................... 5

3 MAIN FEATURES ............................................................................................................. 6

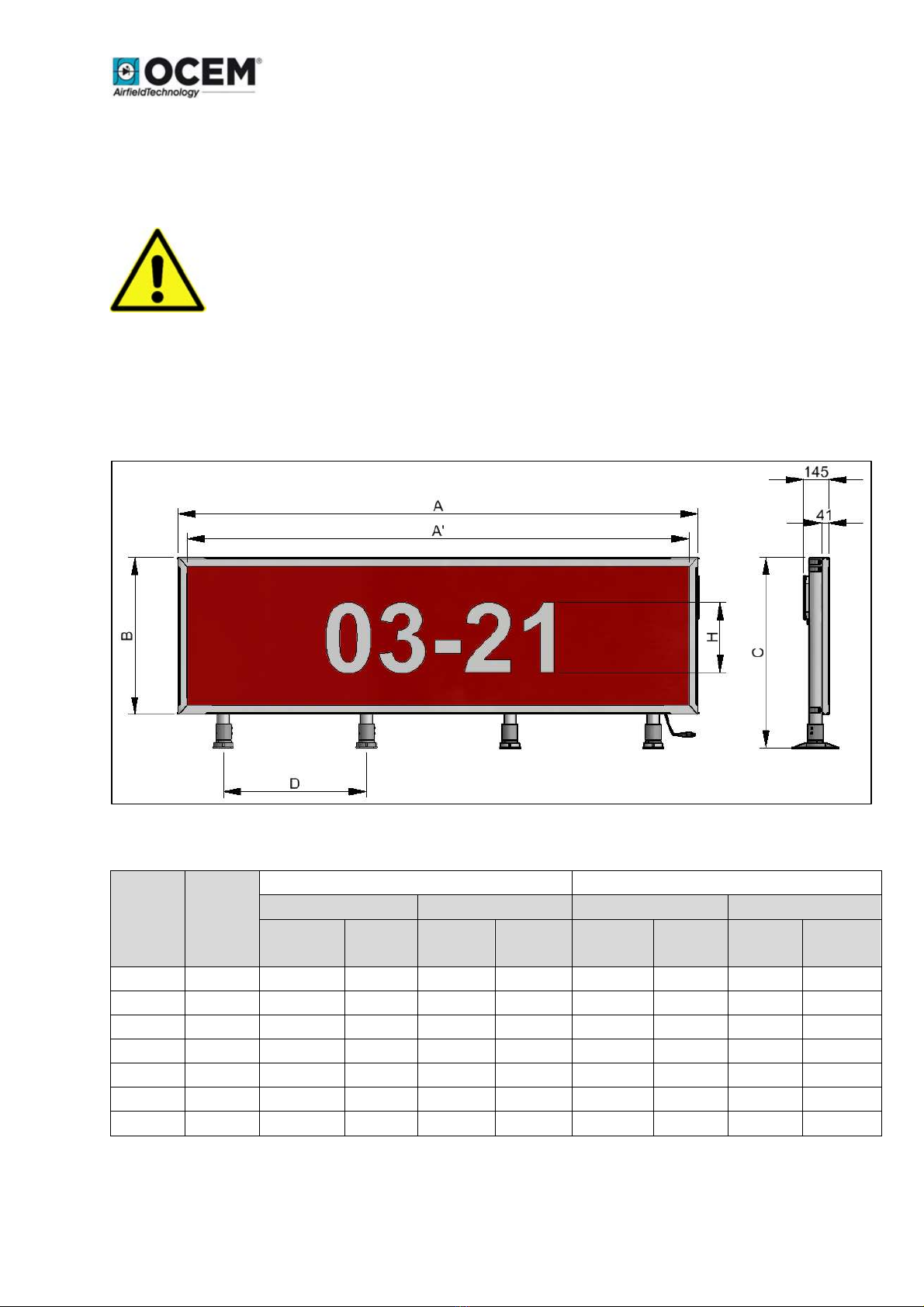

3.1 Signs Description ............................................................................................................ 6

3.1.1 Frame .................................................................................................................... 6

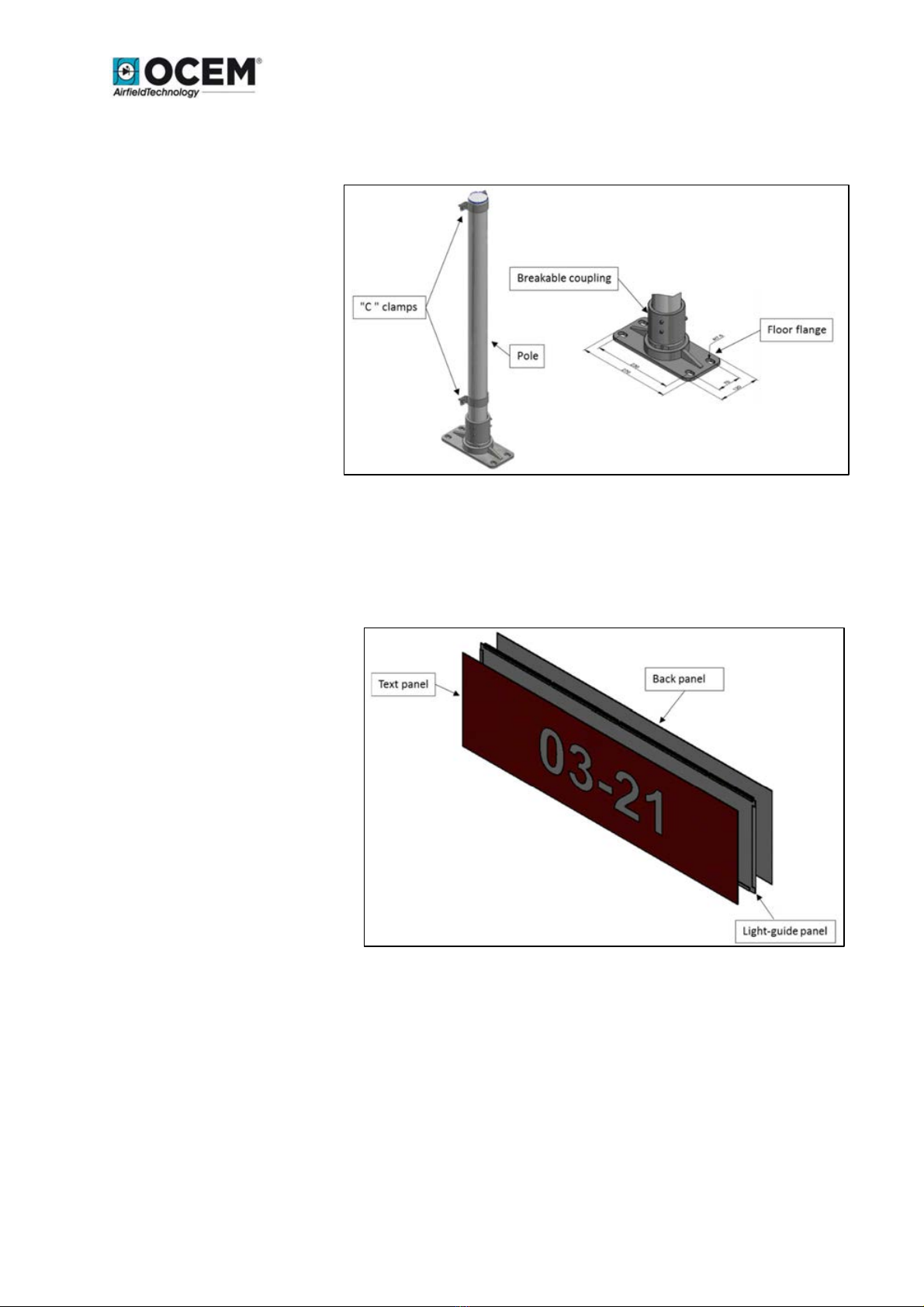

3.1.2 Supports ................................................................................................................ 7

3.1.3 Panels .................................................................................................................... 7

3.1.4 LEDs Luminous Source .......................................................................................... 8

3.1.5 Electrical circuit ..................................................................................................... 8

3.1.6 Protection earthing ............................................................................................. 10

3.1.7 Models ................................................................................................................ 10

3.1.8 Monitoring Option .............................................................................................. 11

3.2 Part Number Identification .......................................................................................... 12

3.3 Environmental data ...................................................................................................... 12

3.4 Electrical Data ............................................................................................................... 13

3.5 Luminance Data ............................................................................................................ 14

4 INSTALLATION .............................................................................................................. 15

4.1 Option 70 Bird Spikes ................................................................................................... 18

5 MAINTENANCE ............................................................................................................. 19

5.1 Periodical Checks .......................................................................................................... 19

5.2 LEDs Luminous Source Replacement ........................................................................... 19

5.3 Electronic Card Replacement ....................................................................................... 23

5.3.1 Series Circuit Signs .............................................................................................. 23

5.3.2 Parallel Circuit Signs ............................................................................................ 25

5.4 Front Panel Replacement ............................................................................................. 28

5.5 Electronic Equipment Replacement ............................................................................. 31

5.6 Troubleshooting ........................................................................................................... 32

5.6.1 Series Signs .......................................................................................................... 32

5.6.2 Parallel Signs ....................................................................................................... 32

6 DRAWINGS ................................................................................................................... 33

6.1 Wiring diagram series signs .......................................................................................... 33

6.2 Wiring diagram parallel signs ....................................................................................... 35

7 LIST OF RECOMMENDED SPARE PARTS .......................................................................... 36

8 ACCESSORIES ................................................................................................................ 37