DAB Blue Diver Series Multistage Submersible pumps are designed for pumping DEF

34% Urea solution (Diesel Exhaust Fluid) only. Never use these pumps for gasoline,

kerosene, diesel fuel or any other distillates or solvents.

ISO 22241 provides the Urea Diesel Exhaust Fluid (DEF) requirements including 1)

quality of Urea DEF solution, 2) applicable test methods, 3) packaging transportation and

storage requirements and 4) refilling interface requirements.

Urea DEF solution must be handled and stored in compatible material, kept free of

contamination, and stored at temperatures that will not cause the solution to deteriorate.

The use of contaminated or out of specification Urea DEF can cause filter problems,

clogged injectors, deterioration of the selective catalytic reduction process, or poison the

vehicle’s catalytic converter used in the exhaust system. Urea manufacturers may

require a system inspection to insure that all components are Urea DEF compatible and

that the tank and system have been properly cleaned, rinsed, and flushed before Urea

DEF is delivered.

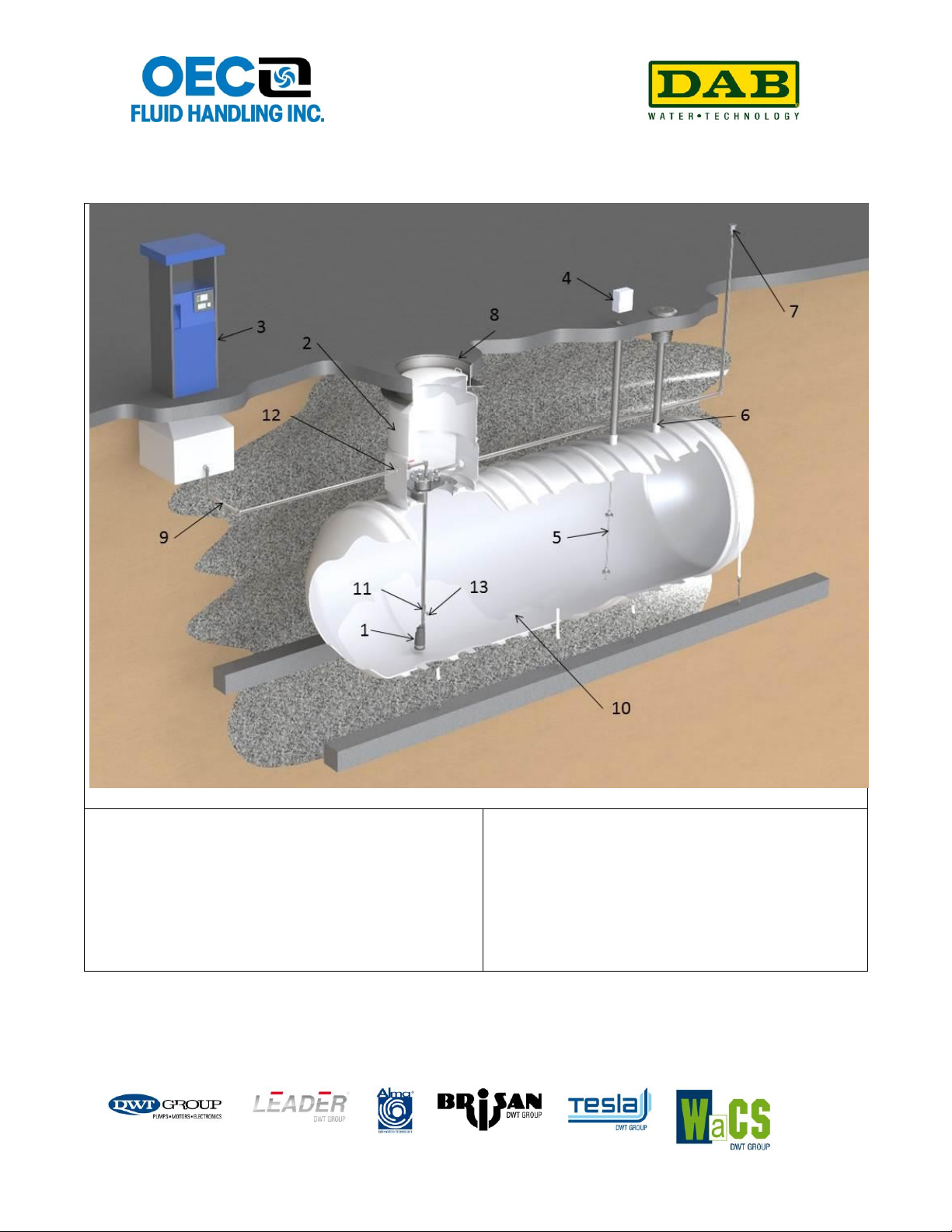

The tank in which the pump is being installed must be vented in accordance with

manufacturer’s installation instructions. Follow the tank manufacturer’s tank installation

instructions.

The use of NPT threaded piping and tank fittings for Urea DEF is not recommended.

Threaded connections are likely to weep urea solution forming urea crystals at the point

of the leak. However, if NPT threaded fittings are used, Urea DEF compatible thread

sealant is necessary to achieve a tight connection. Use only pipe dope that is ISO

22241-2 approved for DEF and suitable for stainless steel. Do not use PTFE-based pipe

tape. Cleaning of all piping systems with deionized or distilled water per ISO 22241-3 is

recommended prior to placing system into service.

A product filter must be installed between the tank / piping and the dispensing point. The

filter should be sized to insure that Urea DEF supplied to the dispenser nozzle meets the

requirements of ISO 22241 and does not pass particulates that may clog the injector

nozzles in the vehicle.

The installation contractor should install the pump so that future service can be easily

performed. Tank access ways, man ways, and pump mounting flanges should be large

enough for the safe and easy removal of the pump for service and replacement.