2

Operating Instructions and Parts Manual 80058

11/18

2018 OEMTOOLS™

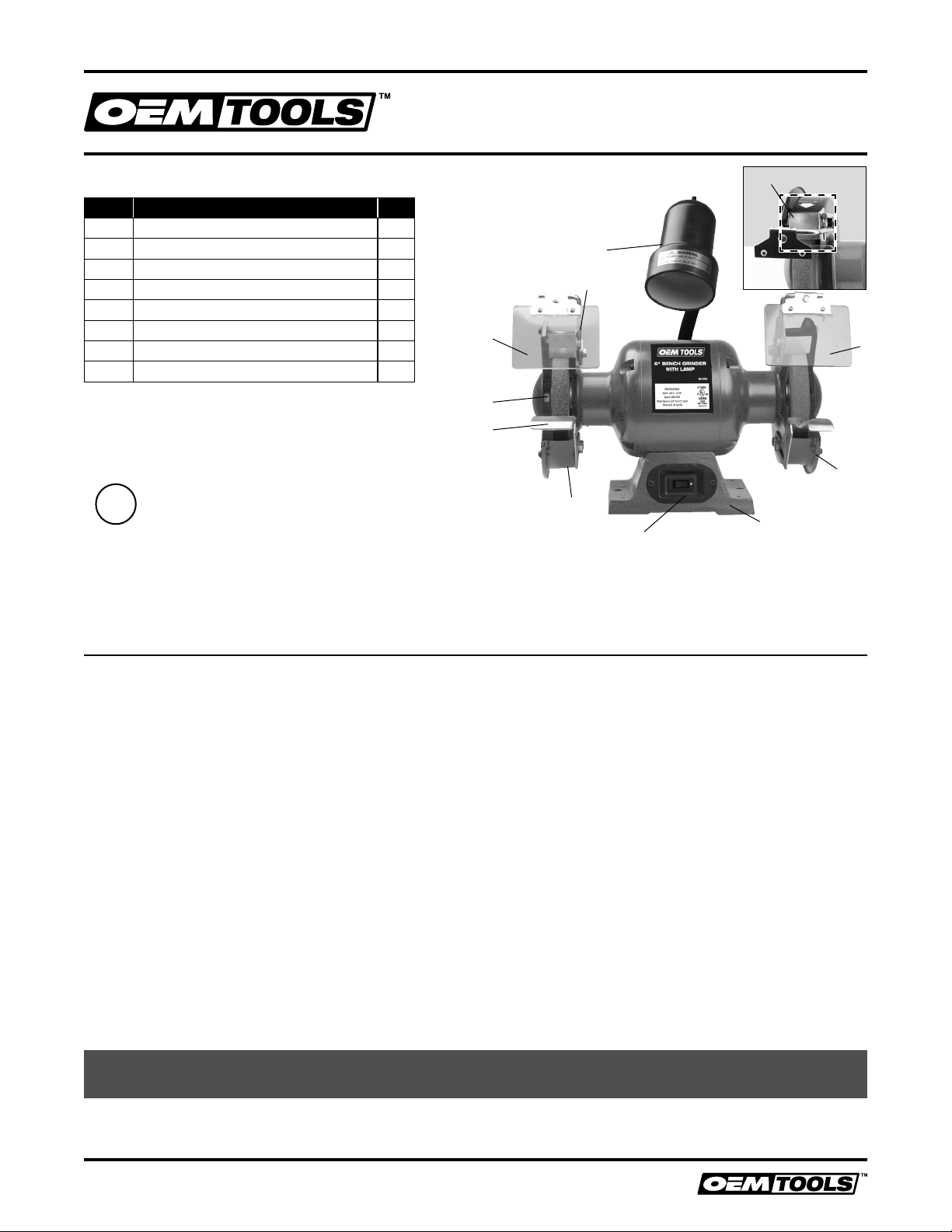

6" BENCH GRINDER WITH LAMP

IMPORTANT INSTRUCTIONS

AND SAFETY RULES

1. Know your tool. Read this manual carefully. Learn the tool’s

applications and limitations, as well as potential hazards specific to it.

2. Ground all tools. If the tool is equipped with a three-pin plug, it should

be plugged into a three-pin electrical outlet. Never remove the ground

pin. DO NOT modify the plug provided. If it will not fit in the outlet, have

the proper outlet installed by a qualified electrician. Failure to properly

ground unit could result in severe electrical shock and/or death. Always try

to avoid body contact with grounded surfaces, such as radiators, cooking

ranges and any other fixed appliance with metal surfaces.

3. DO NOT abuse the electrical cord. Never use the cord to carry tools

or pull the plug from an outlet. Keep the cord away from heat, sharp

edges or moving parts. Always check the extension cords for damage

before use. Replace damaged cords immediately. Damaged cords

increase the risk of electric shock.

4. Keep work area clean and well lit. Cluttered or dark work areas invite

accidents.

5. Keep children away. All children should be kept away from the work

area. Never let a child handle a tool without strict adult supervision.

6. DO NOT operate this tool if under the influence of alcohol or drugs.

Read warning labels on prescriptions to determine if your judgment or

reflexes are impaired while taking drugs. If there is any doubt, do not

attempt to operate.

7. Use safety equipment. Eye protection should be worn at all times when

operating this tool. Use ANSI approved safety glasses. Everyday eye-

glasses are NOT safety glasses. Dust mask, non-skid safety shoes, hard

hat, or hearing protection should be used in appropriate conditions.

8. Wear proper apparel. Loose clothing, gloves, neck-ties, rings,

bracelets, or other jewelry may present a potential hazard when

operating this tool. Keep all apparel clear of the tool.

9. Don’t overreach. Keep proper footing and balance at all times when

operating this tool.

10. Always disconnect the tool from the power source before making

any adjustments, storing, servicing, or changing accessories. Such

preventative safety measures reduces the risk of starting the tool

accidentally.

11. DO NOT use the tool if the switch does not turn it on and off. Any tool that

cannot be controlled with the switch is dangerous and must be repaired.

12. Check for damage. Check your tool regularly. If part of the tool is

damaged, it should be carefully inspected to make sure that it can

perform its intended function correctly. If in doubt, the part should be

repaired. Refer all servicing to a qualified technician. Consult your

dealer for advice.

13. Keep away from flammables. DO NOT attempt to operate this tool

near flammable materials or combustibles. Failure to comply may

cause serious injury or death.

14. Store idle tools out of the reach of children and untrained persons.

Tools may be dangerous in the hands of untrained users.

15. Always remain alert when the grinder is in use. Not paying attention to

what you are doing may lead to serious injury.

16. Use only accessories or attachments that are recommended by the

manufacturer for your model. Accessories that may be suitable for one

tool may become hazardous when used with another tool. Use of non-

recommended accessories may result in injury or damage to the tool.

GENERAL POWER TOOL SAFETY

1. DO NOT expose your power tool to wet or damp conditions and NEVER

use in rain. Regularly check the power cord of your tool and any

extension cord that you are using for damage.

2. DO NOT carry or pull the machine with the power cord. Ensure the

cord is clear from hot surfaces, oil or sharp objects.

3. Before plugging your power tool into the power outlet, make sure the

power tool is in the OFF position.

4. Check that wrenches or adjusting keys have been removed. Any

wrench or key left attached to a moving part can result in injury.

5. Keep your power tool clean and well serviced at all times.

6. Always use the correct tool for the job and never force the tool to work

harder than it is designed.

7. Never use your power tool with broken parts such as switches, guide

fences or leg stands.

8. Only have your power tool serviced by a qualified repair agent using

the manufacturer’s recommended parts.

9. DO NOT force the material being cut.

10. Never stand on a tool.

11. Never leave a tool running unattended.

12. Use the proper extension cord.

13. Avoid prolonged exposure to vibration.

WARNING

1. Only use qualified repair agents to service this power tool.

2. Only use qualified electrician to repair any damaged wiring.

3. NEVER remove the grounding prong from the power cord or extension

cord.

SPECIFIC SAFETY INSTRUCTIONS FOR GRINDERS

1. Always use guards and eye shields when grinding. Always keep

guard in place.

2. Use only grinding wheels having a maximum operating speed at least

as high as the “no load RPM” marked on the tool’s nameplate. Use

only grinding wheels suitable for the speed of the grinder.

3. Use only flanges furnished with the grinder.

4. Adjust distance between wheel and work rest to maintain to 1/8” or

less separation as the diameter of the wheel decreases with use.

5. Before using inspect recommended accessory for cracks or flaws. If

such a crack or flaw is evident, discard the accessory. DO NOT USE A

GRINDING WHEEL THAT IS CRACKED OR FLAWED IN ANY WAY.

6. When starting the tool, let it run for one minute. Never start the tool

with a person in line with the wheel. This includes the operator.

7. DO NOT grind on the sides of grinding wheels unless they are

specifically designed for that purpose.

8. DO NOT overtighten the hex nut. This may crack the grinding wheel.

9. Clean the cavity around the grinding wheel periodically.

WARNING: ALWAYS use safety glasses. Everyday glasses are NOT

safety glasses. Also use face or dust mask if cutting operation is dusty.

ALWAYS WEAR CERTIFIED SAFETY Equipment.

ANSI Z887.1 eye protection (CAN/CSA Z94.3)

ANSI S12.6 (S319) hearing protection

NIOSH/OSHA/MSHA respiratory protection

WARNING: Some dust created by power sanding, sawing. Grinding,

drilling and other construction activities contains chemicals known to the

state of California to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

1. Lead from lead-based paints.

2. Crystalline silica from bricks and cement and other masonry

products.

3. Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies depending on how often you do this

type of work. To reduce your exposure to these chemicals work in a well

ventilated area and work with approved safety equipment such as those dust

masks that are specifically designed to filter out microscopic particles.

Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling and other construction activities. Wear protective clothing and

wash exposed areas with soap and water. Allowing dust to get into

your mouth, eyes or lay on the skin may promote absorption of harmful

chemicals.

WARNING: Use of this tool can generate and/or disperse dust which

may cause serious and permanent respiratory or other injury. Always use

NIOSH/OSHA approved respiratory protection appropriate for the dust

exposure. Direct particles away from face and body.