tooth as necessary to maintain productivity. Make sure you retract the front caster

wheels and keep them off the floor while scraping. This ensures maximum weight

on the front blade as well as extending the life of your front caster wheels.

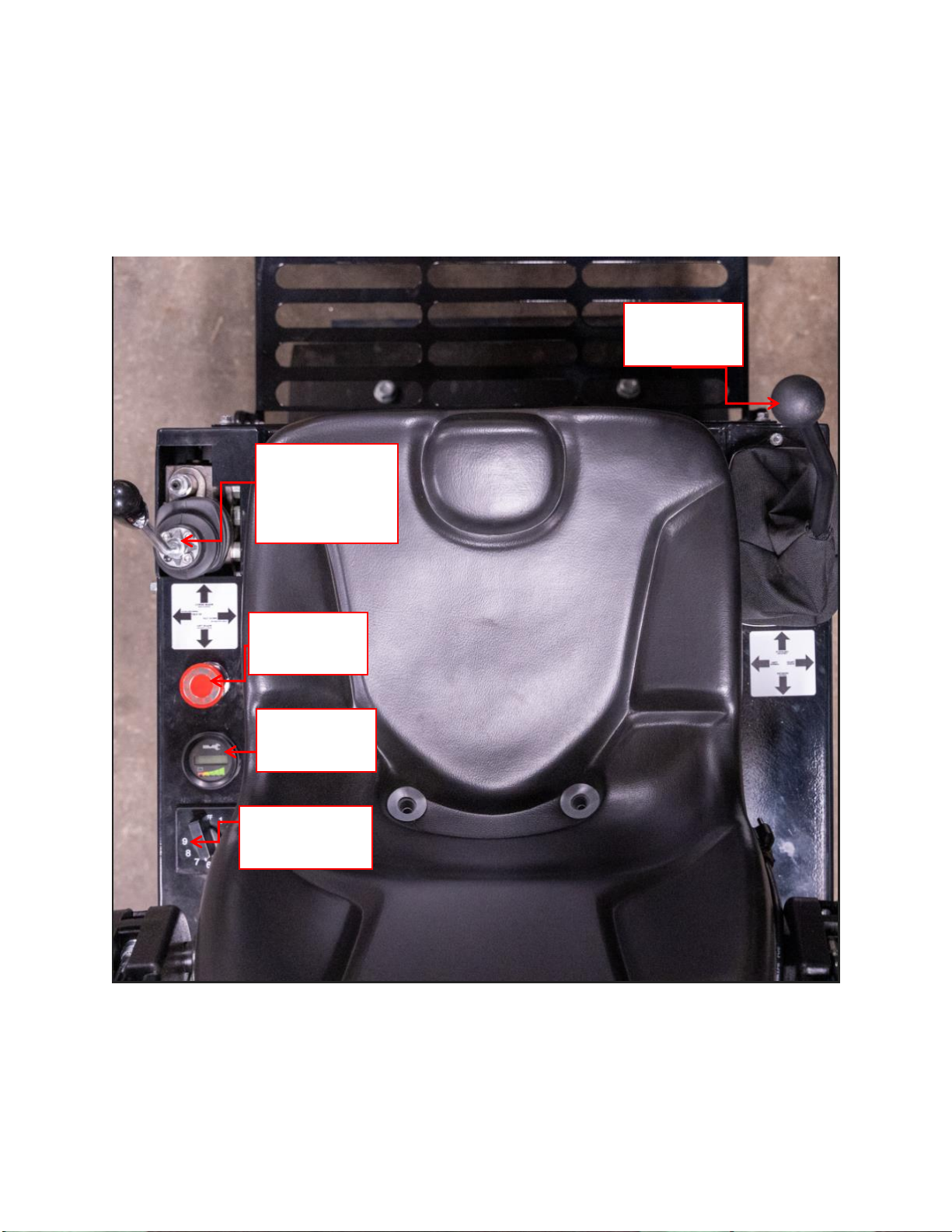

Remember, when you push down the red button to stop the machine for parking, to

make sure it is on a level surface and chock the wheels to prevent the machine

from rolling away. Operators should lower the blade by pressing the left-hand

lever forward each time they get off the machine. This safety practice eliminates

possible bodily injury from lowering the blade by unauthorized operators. Do not

transport machine with front of machine off the surface of floor higher than 1/2".

As battery voltage is consumed through machine use, the voltage meter (left side

instrument panel) will display the battery percentage. This is similar to a gas

gauge but when the readout reaches 20% the machine will go into limp mode (slow

the RPMs down) to let the operator know it needs to be driven to where it will be

charged or loaded up on a trailer. The machine must be charged to begin scraping

again. To charge the batteries with the stand-alone charger:

1. Park machine on a level surface

2. Turn machine off (push red Emergency Stop button down)

3. Plug DC connector from the stand-alone battery charger (Gray connector)

into receptacle on front left side of the machine.

4. Insert AC electrical plug from stand-alone charger into wall outlet

conforming to the voltage of the charger being used.

Your Cyclone is equipped with wheel scrapers that scrape whatever debris you run

over like VCT off the tires. If you notice your Cyclone isn’t getting traction or is

carrying debris around you may have to loosen 2 bolts on the wheel scrapers and

slide them against the tires and retighten.

Change Scraping Blades

Lift blade bar to full UP position. Place a block under blade bar assembly for

safety purposes. Push the red button down to stop the electric motor. Loosen the

pinch or clamp bolt at the rear of the blade holder block using a ¾” wrench. Slide

the dull blade out and insert a new blade up against the shoulder stop. Retighten

the pinch bolt, remove wood block for safety, and resume scraping. The large 1-

1/8” blade holder bolt should not need to be more that hand tight. With a little

practice you should be able to change blades in 15 seconds. Dull blades can be

sharpened and reused many times.