BEFORE YOU START, IT IS IMPORTANT THAT YOU READ THE FOLLOWING INSTRUCTIONS.

• When selecting a site, choose an area that is firm and level yet allows drainage away from the site.

• Although this shed when installed according to instructions, is designed to withstand greater wind loads than

other conventional sheds, do not install it in areas subject to high winds or erect on a windy day. Any

building left partially constructed may be seriously damaged if left in this state. It is your responsibility to safely

and securely anchor the shed, having regard to the windiest conditions in the area. The shed could possibly blow

away causing damage and possible injury if not properly attached to the ground foundation.

• Do not backfill against the walls or base of the shed as this will cause corrosion and void the warranty.

• The prevention of condensation inside the shed will assist in keeping the contents dry as well as minimising any

possible corrosion of the shed itself, the following hints may prove useful.

There is always dampness in soil, and this may rise into the shed if there is no barrier. A heavy duty polythene

sheet may be placed under the concrete slab to prevent evaporation into the shed, (illustrated in Step A).

Seal the space between the bottom frame and the concrete slab with a mastic (except at the front corners) which

does not completely dry out. The front corners are not sealed to enable drainage out of the ends of the front base

rail.

If condensation still presents a problem, panels of polystyrene (5cm thick) may be glued to the interior of the roof

between the supports. Use a glue that is resistant to moisture and temperature. This has the further advantage

of keeping your shed cooler on hot summer days.

• Check the labels on the packs to ensure you have the model shed you ordered and the correct number of

packs.

• You will need a few tools, and some extra equipment which may prove useful to make assembly faster and

easier (these are indicated in the section HOW TO READ THIS MANUAL). All holes for screws are predrilled. A

power screw driver or cordless drill equipped with a magnetic Philips tip will hasten assembly. Take care not to

over-tighten self-tapping screws.

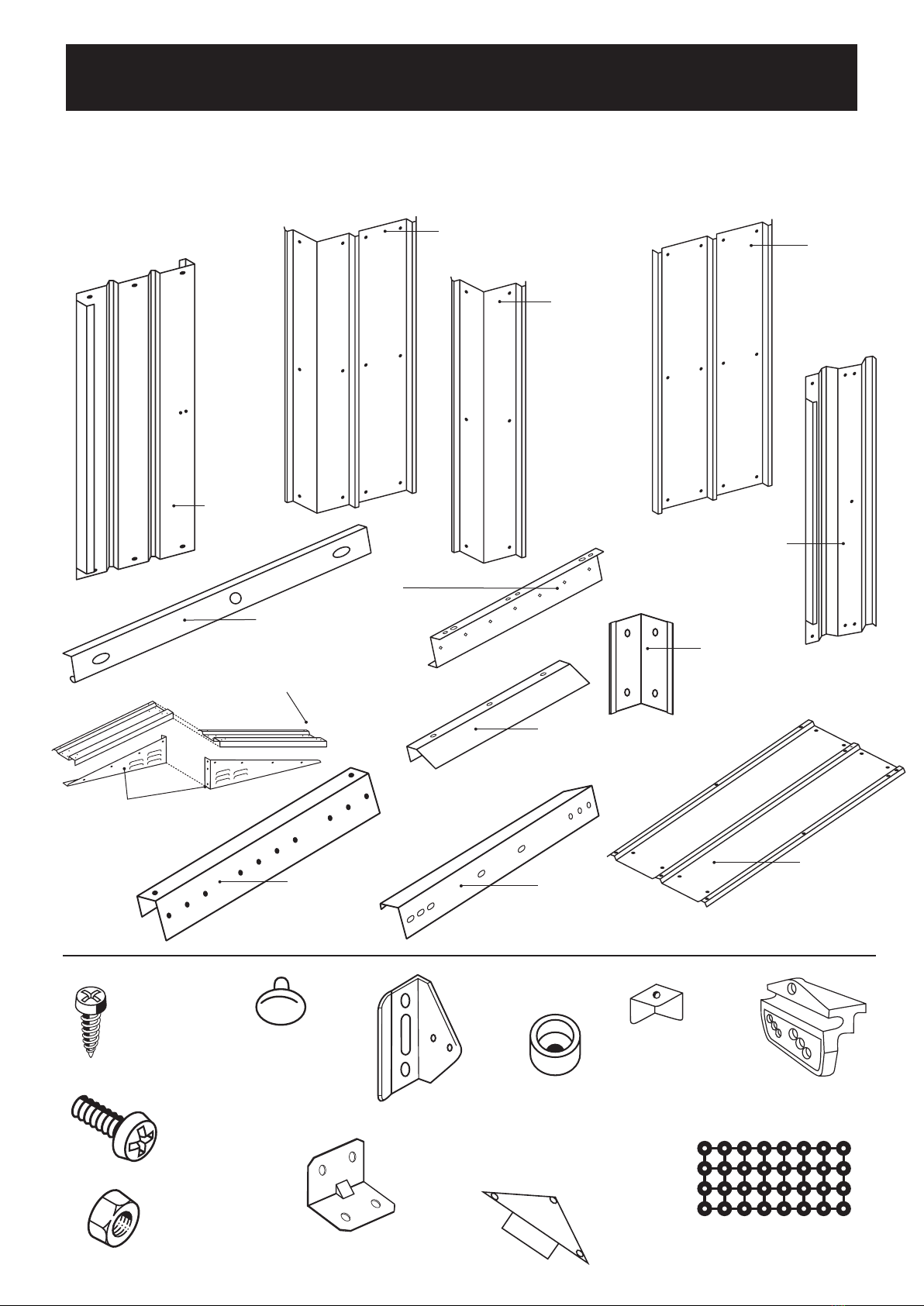

• Sort, separate and identify all parts and hardware before construction. Check against the illustrations shown at

the top of each step illustrated in this manual. Pieces are labelled except for panels, check with the labelling on

the diagrams shown. Not all drawings are to scale since some have been enlarged to enable easier viewing in

comparison to other pieces.

• Since this manual is used to instruct installation of varying sizes of shed, Labelling of Parts in the diagrams has

been simplified as follows:

All the frame work components have the same system of part numbers but indicate different lengths, these part

numbers are stamped into the component.

e.g. Roof Beams 9 foot length = P9, 7 foot length = P7, 5 foot length = P5, 3 foot length = P3

Therefore, in the diagrams the Roof Beam is labelled P.

e.g. Rear Midwall Brace 10 foot length = G1A, 6 foot length = G6A

Therefore, in the diagrams the Rear Midwall Brace is labelled G.A.

• Most helpful of all, get a friend or family member to help you.

When you first unpack your shed, construction may look complicated ... but it really isn’t. Simply follow the

illustrated instructions and your Garden Shed will be erected quickly and accurately.

MODEL (feet) (millimetres) (inches) (millimetres) (feet) (millimetres)

63 6’ x 3’ 1830 x 920 75 1930 5’7” x 2’9” 1710 x 820

65 6’ x 5’ 1830 x 1540 75 1930 5’7” x 4’9” 1710 x 1440

67 6’ x 7’ 1830 x 2160 75 1930 5’7” x 6’9” 1710 x 2060

69 6’ x 9’ 1830 x 2780 75 1930 5’7” x 8’9” 1710 x 2680

83 8’ x 3’ 2450 x 920 77 1980 7’7” x 2’9” 2330 x 820

85 8’ x 5’ 2450 x 1540 77 1980 7’7” x 4’9” 2330 x 1440

87 8’ x 7’ 2450 x 2160 77 1980 7’7” x 6’9” 2330 x 2060

89 8’ x 9’ 2450 x 2780 77 1980 7’7” x 8’9” 2330 x 2680

103 10’ x 3’ 3070 x 920 79 2030 9’8” x 2’9” 2950 x 820

105 10’ x 5’ 3077 x 1540 79 2030 9’8” x 4’9” 2950 x 1440

107 10’ x 7’ 3077 x 2160 79 2030 9’8” x 6’9” 2950 x 2060

109 10’ x 9’ 3077 x 2780 79 2030 9’8” x 8’9” 2950 x 2680

1

THIS MANUAL WILL BE USED FOR THE FOLLOWING GARDEN SHED MODEL NUMBERS

APPROX. ROOF DIMENSIONS OVERALL HEIGHT APPROX. BASE DIMENSIONS

INSTALLATION ADVICE