6 IMTP2.2-ITTP2.2/4/5.5/7.5 ENG

5.2 Pump hydraulic connection

Connectthehydraulicsaccordingtotheregulationsinforce.

Thisproductcanworkwhenconnectedtothewaterworksortakingwaterfromawatercistern.

If you connect the system to the waterworks, you have to respect the regulations in force issued by local

authority(Common,localauthority,etcÉ).Itisimportanttoputapressureswitchontheinletleader;itswitches

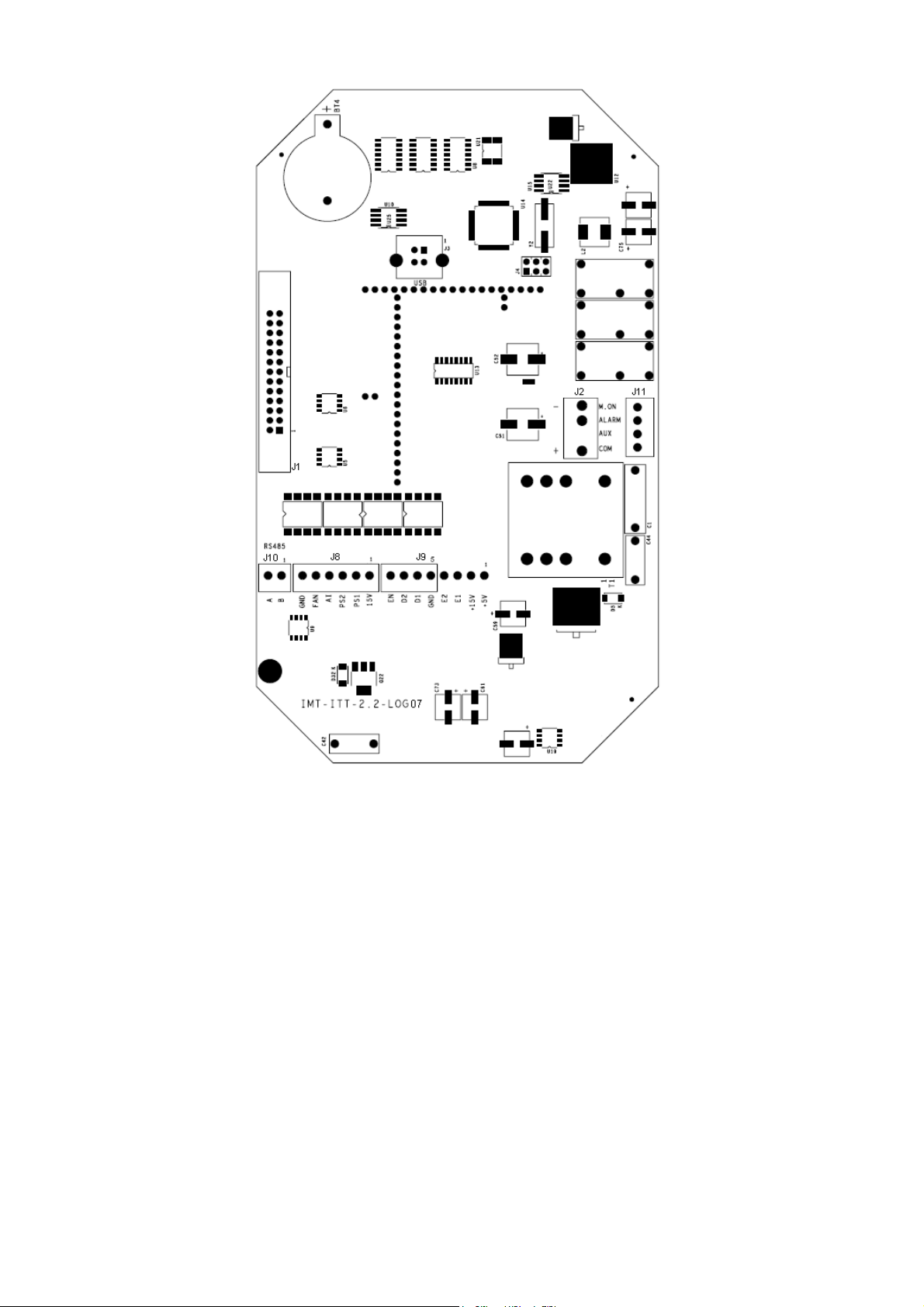

offthemotorpowerincaseoflowpressure(itisadry-workingexternalprotection).Theinverterhavetwoports

foranormally-closedgenericcontact:ENandConthelogicboard(fig.4).

Verifytheamountofpressurebetweenthewaterworksandthemaximumpumppressure,doesnotexceedthe

maximumpumppressurevalue(nominalpressure)

Besides,itisimportanttoputapressuregaugeontheoutletleader,soitispossibletoregulatethepressure

factorysettingvalue,accordingtotherealconditionsofthesystem.On the outlet leader it is necessary to install

a pressure gauge with an output signal between 0 – 5 Vdc or 4 – 20 mA; this signal is an input to the inverter.

Asaruleitwouldbebettertoinstallflexibleorrigidpipesoninletandoutletbranches,on-offvalvesoninletand

outletbranches,anoreturnvalve,amembranesurgetank.Toavoiddryingthesystemforreplacementofthe

membranesurgetank,pressuregaugeorpressuretransducer,itwouldbebettertoinstallsomeon-offvalves

betweenthetankconnectionandthesystem.Putthepressuretransducerdownstreamthenon-returnvalve,ifit

ispresent.Itwouldbebettertoinstallacock,usedduringthesystemcalibration;itisnotnecessaryifthereis

anexitnearthepump.Besurethesurgetankallowsthesystempressure.

Checkthepre-stresspressureofthesurgetankbeforeconnectingittothesystem.

5.3 Electric connections

Checkvoltageandfrequencyofthepowersupplyarethesameofthenominalvaluesofthecontrolsystem,that

arewrittenonthebox.Becertainofhavingagoodshort-circuitprotectioninyourelectricsystem.

Beforeworking,becertainallthecircuitiswithoutvoltage(alsotheconnectionsvoltageclear).Disconnectthe

inverterfromthepowersupplybeforeworkingonelectricalormechanicalpartsofthesystem.

Waitatleast2minutesafterthepowersupplydisconnectionbeforeworkingontheinverter;this

allow the capacitors discharge (in order to be sure they are completely discharged, the led

placedinsidetheinverter,ontheelectronicboard,havetobecompletelyswitchedoff).

Ifthelocalregulationaboutelectricsystemprovidesforamagneto-thermaldifferentialswitch,

installone.Selecttheprotectionwithcurveforalternativecurrentorpulsingcurrent(typeAorC).

Theunitisequippedwithallthosetechnicalarrangementsrequiredtoensureagoodfunctioningundernormal

situationsinstallation.

The control system has a entry-filter and it conforms to the EMC directive, also have a current overload

protectionwhichguaranteesabsoluteprotectionwhentheInverteriscombinedwithmotorsthatnotexceed the

maximumpower.

IMPORTANT: For EMCis necessary that thepower wires of control panel and motor power wires (when the

motorareseparatedfromtheinverter)areshieldedtype(orarmoured)withindividualconductorsofappropriate

section (current density <= 5 A/mm2). These cables must be the minimum length necessary. The screen

conductormustbeconnectedtothegroundbybothsides.Onmotorusethemetalcaseforconnectiontothe

groundofthescreen.

To avoid loops that can create mass disturbances radiated (antenna effect), the motor operated by the

frequency converter must be connected on the ground individually, always with a low-impedance using the

metallicboxofthemachine.

ThewiresfrompowersupplytofrequencyconverterandwiresfromfrequencyconverterÐmotor(ifthemotoris

separatedtotheInverter)mustbespacedasmuchaspossible,nottocreateloops,notmakethemrunparallel

lessthan50cm.

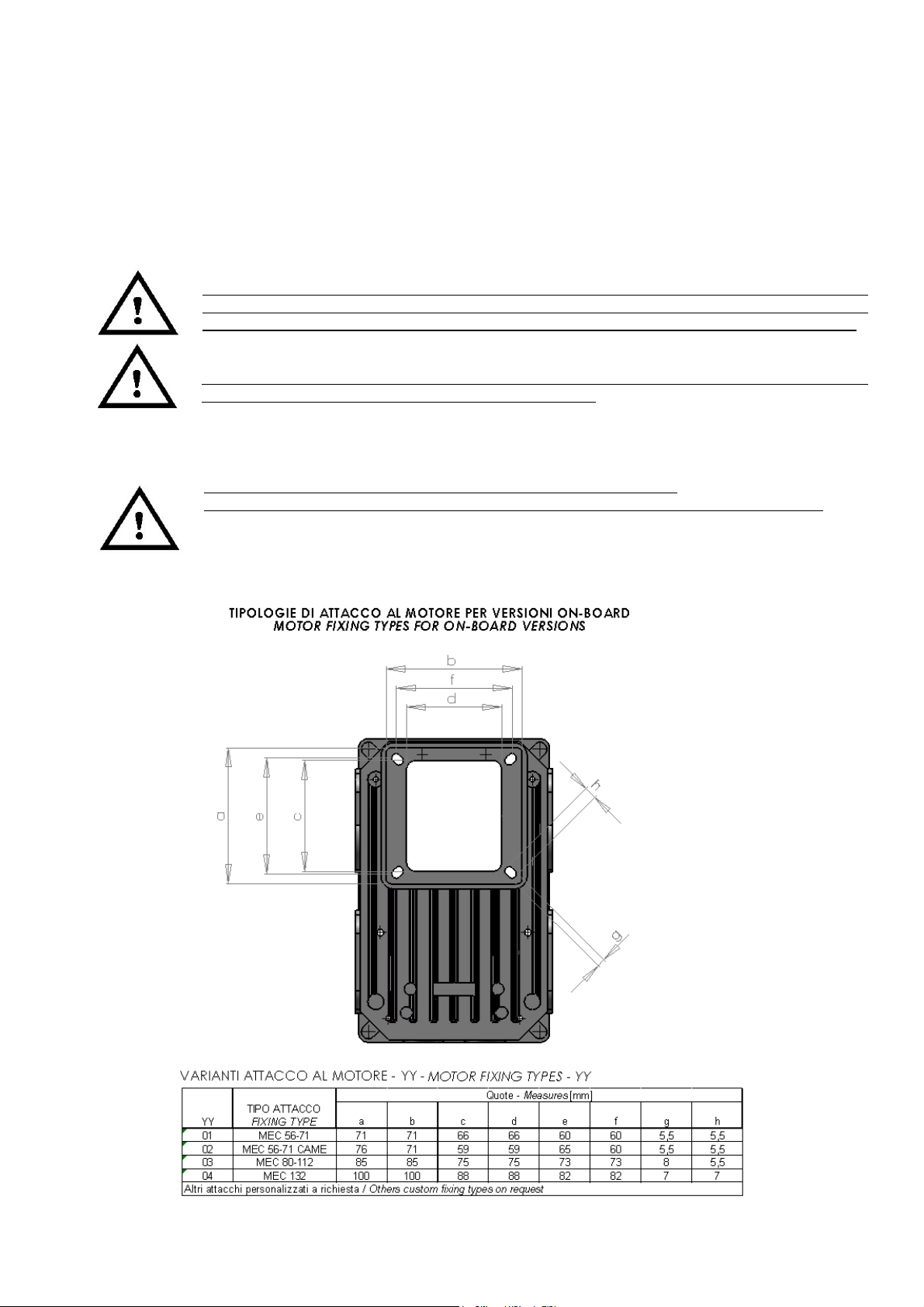

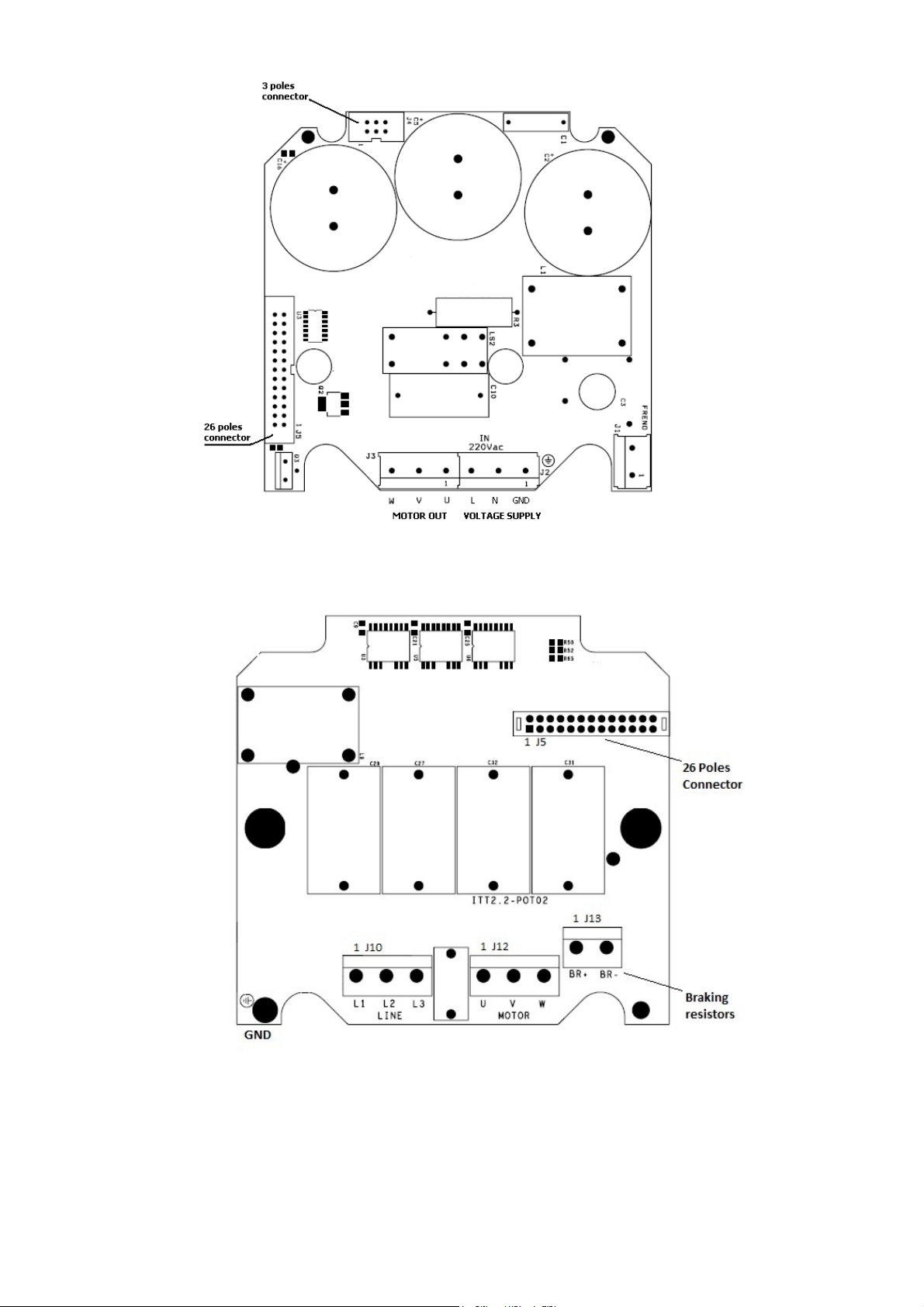

5.4 Motor-pumps phases connection

The single-phase inverter IMTP2.2 must be

installed on asynchronous three-phase motor

with 100-240Vac 50/60 Hz voltage supply.

Phases must be configured to Delta mode if

the motor is 230V / 400V (most common

case,asinFigure3).

Figure 3 – Delta motor phases connection