3

Contents

1. Important Information .....................................................................................................................................................5

1.1 Product Range.................................................................................................................................................5

1.2 Target Group....................................................................................................................................................5

1.3 Symbols Used..................................................................................................................................................5

2. Safety Overview...........................................................................................................................................................5

2.1 Important Safety Instructions.........................................................................................................................5

2.2 Explanation of Symbols..................................................................................................................................6

2.3 Radio Interference Statement .......................................................................................................................7

3. Product Description........................................................................................................................................................7

3.1 About 2-in-1 Unit..............................................................................................................................................7

3.2 Highlights..........................................................................................................................................................8

3.3 Terminals Introduction....................................................................................................................................8

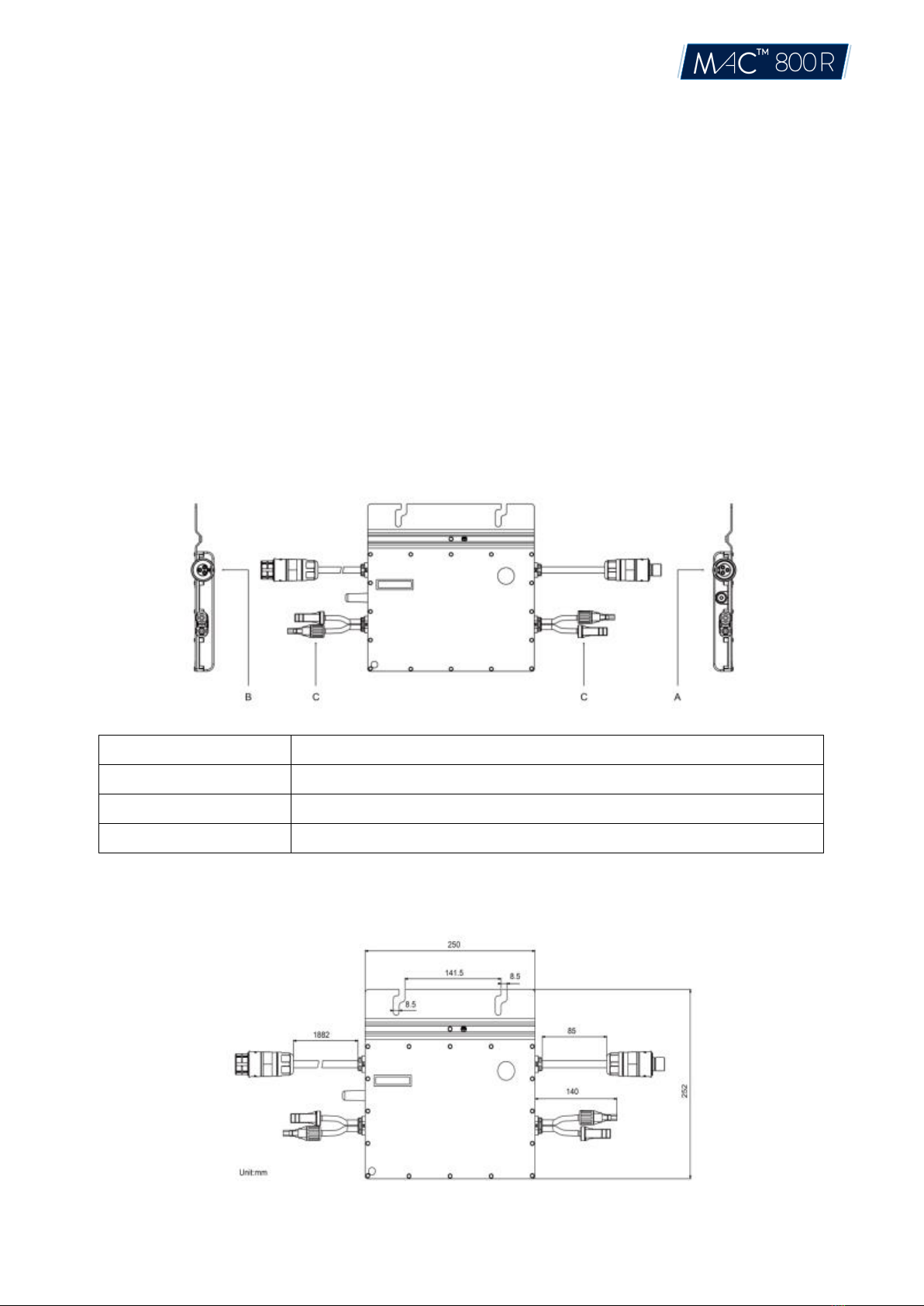

3.4 Dimension(mm) ...............................................................................................................................................8

4. Product Function.......................................................................................................................................................9

4.1 Work Mode.......................................................................................................................................................9

5. Installation Guide ...................................................................................................................................................9

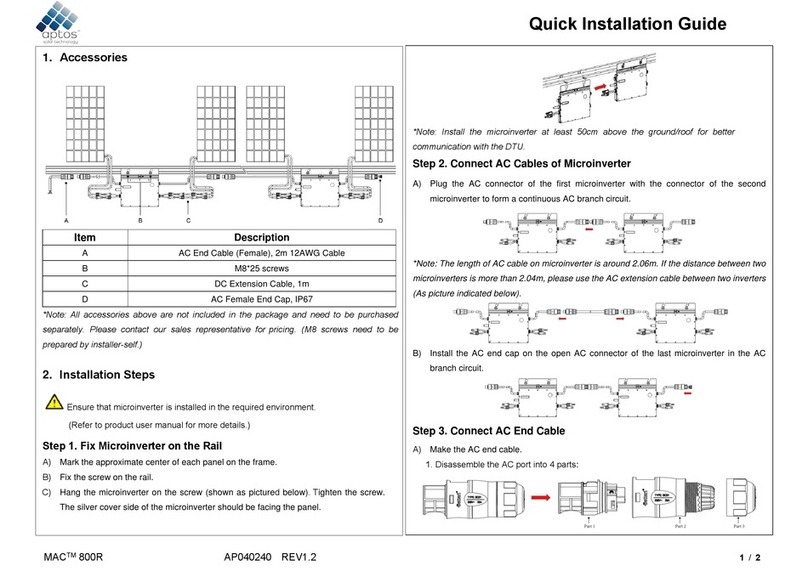

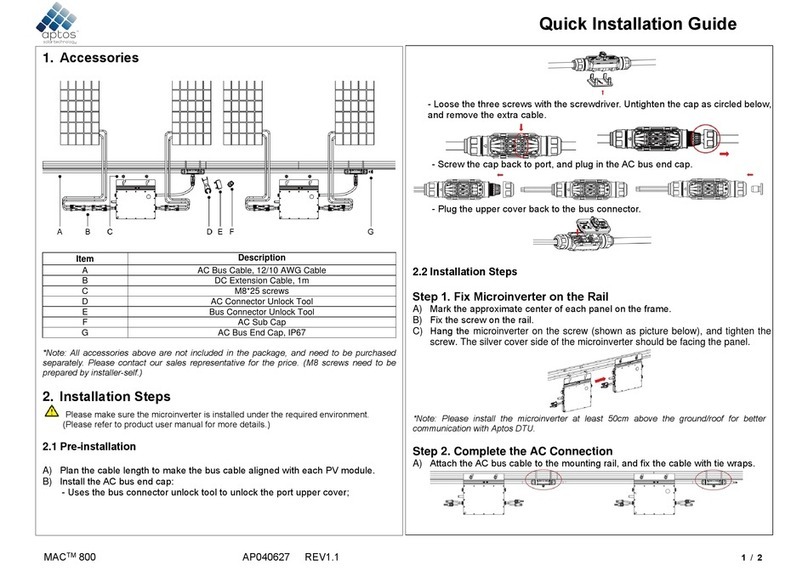

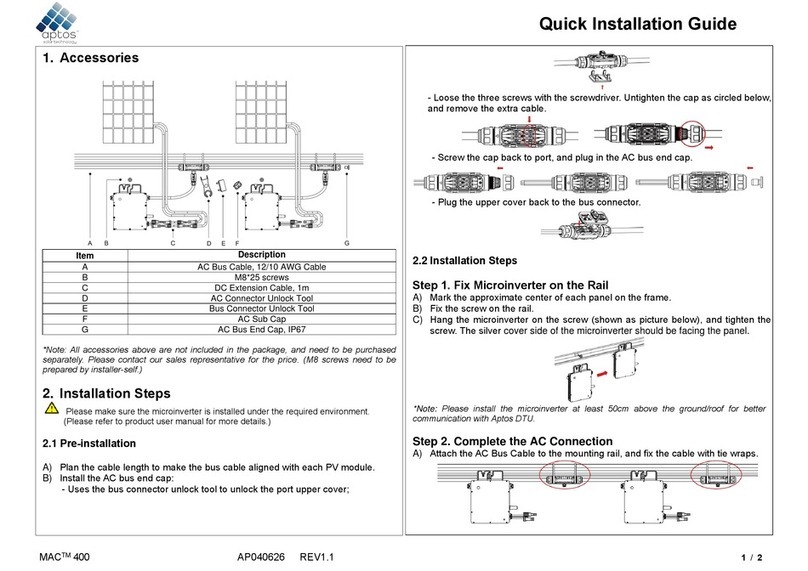

5.1 Accessories......................................................................................................................................................9

5.2 Installation Precaution ..................................................................................................................................10

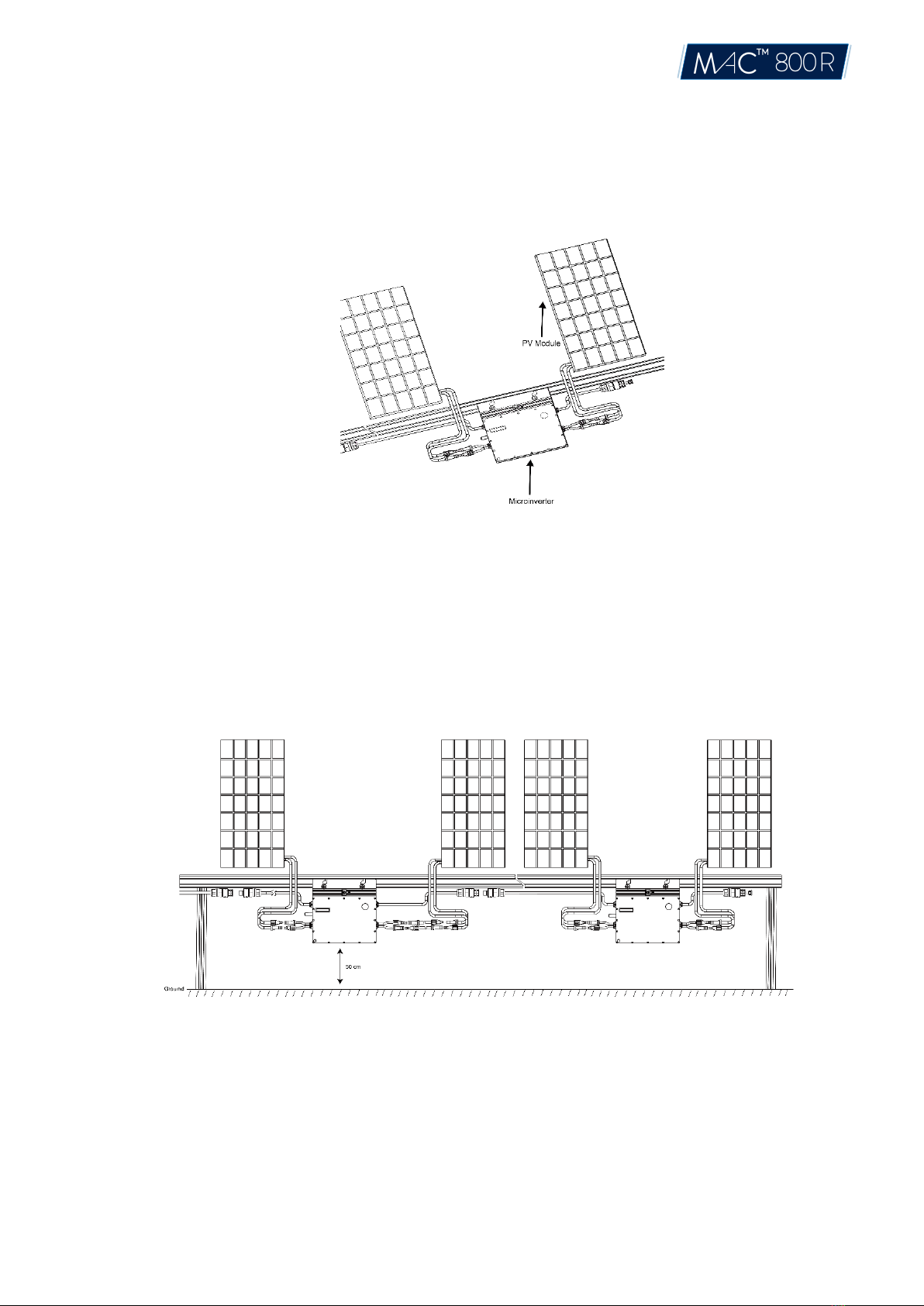

5.3 Space Distance Required ............................................................................................................................10

5.4 Preparation.....................................................................................................................................................10

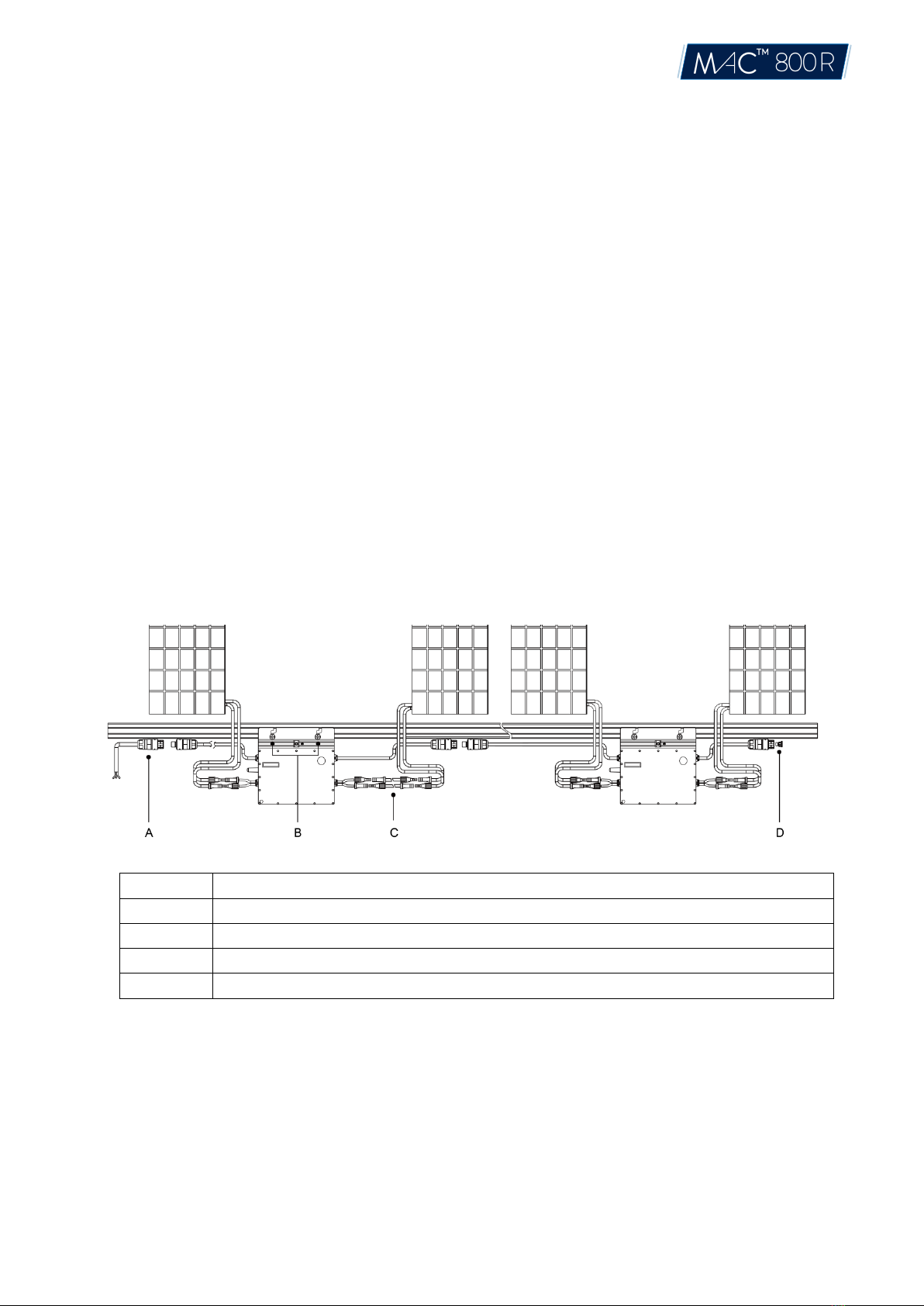

5.5 Installation Steps...........................................................................................................................................11

6. Troubleshooting ...................................................................................................................................................15

6.1 Troubleshooting List .....................................................................................................................................15

6.2 Status LED Indicator.....................................................................................................................................18

6.3 On-site Inspection (For qualified installer only) ........................................................................................19

6.4 Routine Maintenance....................................................................................................................................20

6.5 Replace Microinverter...................................................................................................................................21

7. Decommissions....................................................................................................................................................22

7.1 Decommissions .............................................................................................................................................22

7.2 Storage and Transportation.........................................................................................................................22

7.3 Disposal..........................................................................................................................................................22

8. Technical Data .....................................................................................................................................................22

© 2021 Aptos Solar Technology, LLC. All rights reserved.