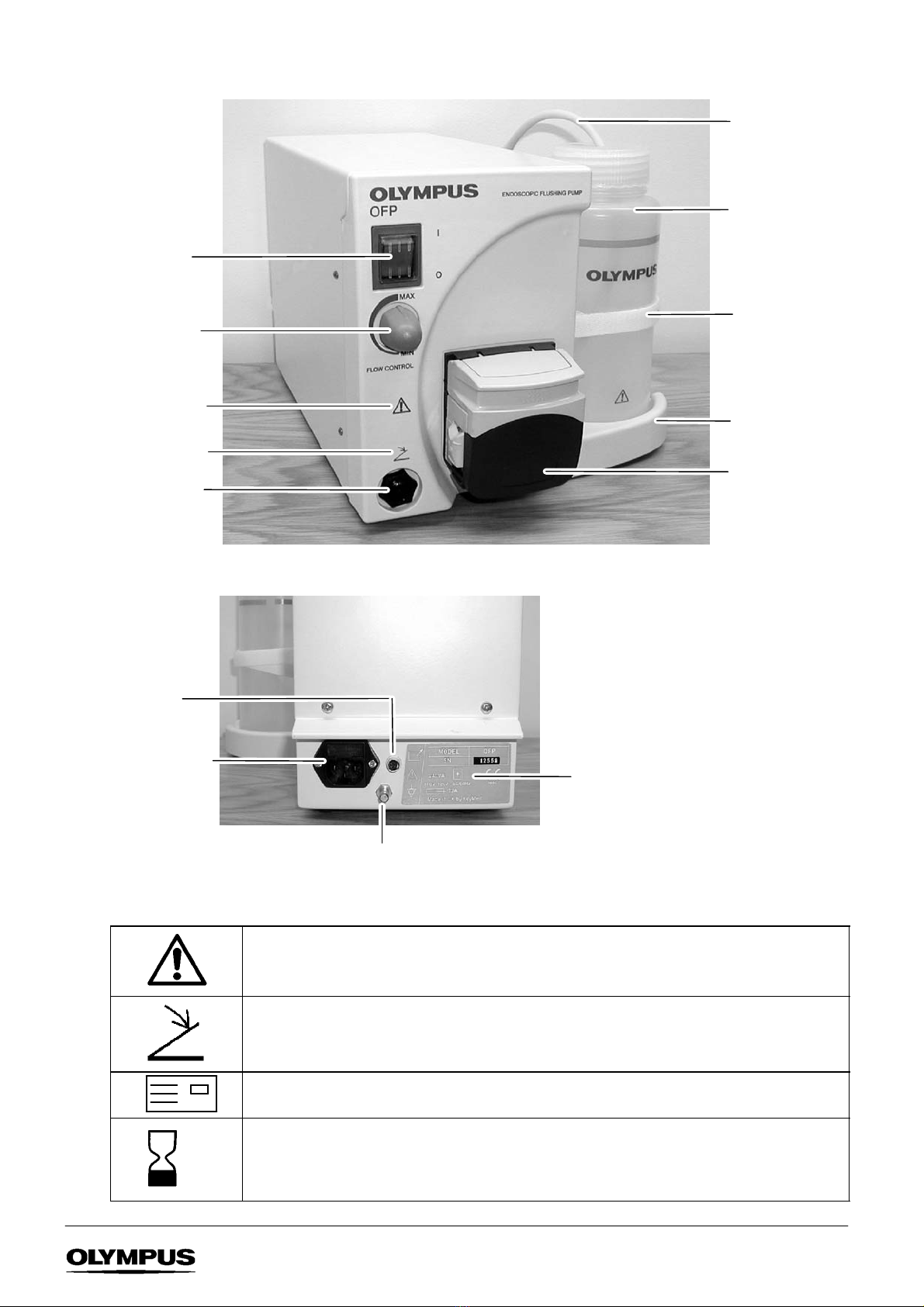

FLUSHING PUMP OFP

3

2OPERATING PRECAUTIONS

2.1 Explosion hazard -- never install or use the OFP within the zone of risk of flammable gases.

2.2 The OFP should only be used in a medical facility under the direction of a trained physician.

2.3 The operator must assess the condition of the patient and use clinical judgement to set the flow rate from the pump to a

suitable level to avoid patient trauma. The flow control should always be set to MIN at the start of the procedure and be

increased progressively to a level commensurate with the clinical condition of the patient and degree of washing required.

Note that when the flow control is set to MAX, the flow rate through the washing channel of the endoscope will be in

excess of that which can be delivered when using a 50ml syringe.

2.4 Use only in conjunction with Olympus EVIS EXERA series endoscopes having an auxiliary water inlet.

2.5 Only use the Olympus auxiliary water tube (MAJ--855) and irrigation tube supplied to connect the OFP to the endoscope,

otherwise patient safety may be compromised or damage to the pump may occur.

2.6 Note that the luer lock connector on the MAJ--855 which attaches to the OFP filter includes a one--way valve to prevent

backflow -- do NOT use the MAJ--855 without this connector in place, or irrigation tube and filter, container contamination

and damage may result.

2.7 The irrigation tube and filter MUST be autoclaved before use.

2.8 The irrigation tube and filter MUST be replaced daily -- failure to do so may lead to patient infection and a reduction in

equipment performance.

2.9 Reprocess the MAJ--855 following each use according to the manufacturer’s instructions supplied with the product.

2.10 Check the “USE BY” date of the tubing as indicated on the packaging label. Do not use any tubes beyond the specified

“USE BY” date.

2.11 Never allow the fluid container to run dry, otherwise air will be supplied to the patient.

2.12 To prevent free--flow of fluid to the patient, do not open the pump cover when the OFP is connected to an endoscope which

is inserted into the patient and ensure the OFP is positioned below patient level.

2.13 If the filter becomes blocked or the irrigation tube from the pump to the fluid container is blocked or kinked, the flow rate will

be noticeably reduced. Check the tube for kinks or blockages and the filter for contamination, replace if necessary.

2.14 Should the OFP be operated with a blocked endoscope or filter, damage to the irrigation tube may occur. In this event, care

must be taken when disconnecting the fluid path as the system may be pressurised. To depressurise the system, the pump

head should be opened to allow fluid back into the bottle. This must only be carried out with the endoscope removed from

the patient. The filter and irrigation tube MUST be replaced before the unit is reused.

2.15 Always switch off the pump before fitting or replacing the irrigation tube.

2.16 When the irrigation tube has been correctly installed and the pump operated,do notdisturb theposition ofthe irrigationtube

eg: by opening the pump head, otherwise the irrigation tube must be replaced. Failure to do so may lead to a reduction in

equipment performance.

2.17 Periodically inspect the MAJ--855 for obvious signs of wear or damage and replace if necessary or as recommended in the

manufacturers instructions.

2.18 Periodically inspect the fluid container for obvious signs of wear or damage and replace if necessary.

2.19 Always empty the fluid container before moving the equipment. Care should be taken to obtain a firm grip underneath the

body of the equipment before moving. The fluid container holder must never be used as a hand hold or carrying handle.

2.20 Store and use the OFP within the environmental conditions described in Section 8; failure to do so may lead to equipment

malfunction or failure.

2.21 Only use replacement parts as specified in Section 7. Failure to do so may lead to equipment malfunction or failure.