Watermark Puretec Commercial SOL-2CI Series User manual

2 Installation & Operation Manual Copyright © Puretec Pty Ltd 2022

What's Inside

What's Inside

Puretec Customer Service ............................................................................................................................3

Installation Record ............................................................................................................................................4

Before Installation..............................................................................................................................................5

Dimensions.............................................................................................................................................................7

Model Information..............................................................................................................................................8

Exploded Diagram...........................................................................................................................................12

Parts Identification..........................................................................................................................................13

Installation Procedure...................................................................................................................................13

Valve & DP Programming ...........................................................................................................................18

Setup Programming .......................................................................................................................................21

Start-Up ................................................................................................................................................................28

Regeneration......................................................................................................................................................29

Replenishment of Salt Supply ..................................................................................................................29

Type of Salt to Use.........................................................................................................................................29

Brine Tank Clean-Out (Yearly)...................................................................................................................29

Media Replacement........................................................................................................................................29

Troubleshooting Guide..................................................................................................................................30

Warranty...............................................................................................................................................................35

3Copyright © Puretec Pty Ltd 2022 SOL-2CI Commercial Series User Guide

Puretec Customer Service

Puretec Customer Service

Thank you for purchasing a Puretec Sorol Water Soening System. Your system is a

proven performer manufactured from only quality materials and components. It will give

years of reliability and trouble free operation if maintained properly.

This user guide is designed for Puretec SOL-2CI Water Treatment Systems. Be careful to

ensure the information and illustration is applicable to your particular unit.

Caution: Do not use with water that is microbiologically unsafe or without

adequate disinfection before or aer the system.

The systems are designed for metropolitan supply water but can be used in other

situations. For other types of water supply, please contact your local Puretec dealer.

Puretec Water Soeners are designed to run economically for many years, dependent on

the initial installation and periodic maintenance.

• Flush system for 5 minutes or more, aer any period of non-use, greater than 2

weeks.

Note: Water soener salt not supplied.

Installation Note: A water filter system/tap, like any product, has a limited life and may

eventually fail. Also sometimes failure happens early due to unforeseen circumstances.

To avoid possible property damage, this product should be regularly examined for

leakage and/or deterioration and replaced when necessary. A drain pan, plumbed to an

appropriate drain or outfitted with a leak detector, should be used in those applications

where any leakage could cause property damage, and/or the water supply should be

turned off if no one is home/present.

INSTALLATION SHOULD BE COMPLETED BY QUALIFIED TRADESPEOPLE. FAULTY

OPERATION DUE TO UNQUALIFIED PERSONS WILL RESULT IN VOIDED WARRANTY

COVERAGE.

Warning: Chlorine (free chlorine) tolerance is 1ppm - high chlorine levels permanently

damage the soening resin & is not covered under warranty. If chlorine exceeds this

limit, we recommend a carbon pre-filter such as the WH2 or CFS Series. Please refer to

Puretec for a specific recommendation. In any case, a carbon pre-filter is recommended

to protect against chlorine spikes & prolong the resin life.

4 Installation & Operation Manual Copyright © Puretec Pty Ltd 2022

Product Information

Model Number:

Serial / Batch Number:

Purchased from:

Date of Installation:

Installer / Plumber Details:

Regen Frequency: ________ Days

Water Analysis Information

Hardness: ___________ ppm / mg/L

Iron: ___________ ppm / mg/L

Manganese: ___________ ppm / mg/L

pH: ___________

TDS (Total Dissolved Salts): ___________ ppm / mg/L

Conductivity: ___________ EC / uS/cm

Chloride: ___________ ppm / mg/L

Sodium: ___________ ppm / mg/L

Installation Record

For future reference, fill in the following data:

Installation Record

5Copyright © Puretec Pty Ltd 2022 SOL-2CI Commercial Series User Guide

Before Installation

Professional Installation Required

• Installation typically requires shutting the water supply, cutting the water supply

pipe and using a welding torch to add piping and fittings. Specialised tools and skills

are required; this must be completed by a qualified tradesperson.

Make Sure Your Water Has Been Thoroughly Tested

• An analysis of your water should be made prior to the selection of your water

treatment equipment. Enter your analysis information on page 4 for your permanent

record.

• Soeners are designed to reduce hardness but can handle reasonable amounts

of soluble iron if consideration is given to content when selecting model and

regeneration settings. For best results contact Puretec to discuss.

Install Water Conditioning Equipment Correctly

Select the location of your water soener with care. Various conditions which contribute

to proper location are as follows:

• Install as close as possible to a drain.

• Install in correct relationship to other water treatment equipment. Contact Puretec

for assistance.

• Install the soener in the supply line BEFORE the water heater. Temperatures above

40°C (104°F) will damage the soener and void the warranty.

• DO NOT install the soener in a location where freezing temperatures occur.

Freezing may cause permanent damage and will also void the warranty.

• DO NOT install where water hammer conditions may occur without installing an

arrestor.

• Allow sufficient space around the installation for easy servicing. Provide a non-

switched 240V power source for the control valve.

• Protect from pressure vacuum with a suitable vacuum breaker.

• For point of entry installations an approved backflow prevention device must be

installed.

• Where line pressure exceeds 500 kPa, an approved pressure limiting device must be

installed to comply with Australian & New Zealand Plumbing Standards. (Ref. AS/NZS

3500.1:2021, Clause 3.3.4).

Before Installation

6 Installation & Operation Manual Copyright © Puretec Pty Ltd 2022

Before Installation

• The control valve, fittings and/or bypass are designed to accommodate minor plumbing

misalignment but are not designed to support the weight of a system or the plumbing.

• Do not use petroleum jelly, oils, other hydrocarbon lubricants or spray silicone anywhere.

A silicon lubricant may be used on the black o-rings but it is not necessary.

• Do not use pipe dope or other sealants on threads. Thread seal tape is the preferred

sealant but is not necessary on the nut connection or caps because of O-ring seals.

• All plumbing should be done in accordance with local plumbing codes. The pipe size for

the drain line should be a minimum of 1”.

• Avoid getting primer and solvent cement on filter system.

• Install grounding strap on metal pipes if required.

• Ensure the system is protected against high pressure and extreme temperatures.

• Chlorine (free chlorine) tolerance is 1ppm - high chlorine levels permanently damage

the soening resin & is not covered under warranty. If chlorine exceeds this limit, we

recommend a carbon pre-filter such as the WH2 or CFS Series. Please refer to Puretec

for a specific recommendation. In any case, a carbon pre-filter is recommended to

protect against chlorine spikes & prolong the resin life.

Things to Remember While Planning Your Installation:

• All installation procedures MUST conform to local plumbing codes.

• If lawn sprinklers, a swimming pool, or geothermal heating/cooling or water for other

devices/activities are to be treated by the soener system, a larger model MUST

be selected to accommodate the higher flow rate, treated water volume, plus the

backwashing requirements of the soener system. Contact Puretec for assistance.

WARNINGS

Note: Solder joints must be done prior to connecting to the valve fittings. Leave at least

6” between the fitting and solder joints when soldering pipes. Failure to do this could cause

heat damage to the fittings.

This should be carried out by a qualified tradesperson.

The nuts and caps are designed to be unscrewed or tightened by hand or with the special

plastic spanner provided. If necessary pliers can be used to unscrew the nut or cap. Do not use

a pipe wrench to tighten or loosen nuts or caps. Do not place screwdriver in slots on caps and/

or tap with a hammer.

7Copyright © Puretec Pty Ltd 2022 SOL-2CI Commercial Series User Guide

Dimensions

Dimensions

SOL110-2CI SOL160-2CI SOL270-2CI SOL380-2CI

Width (mm) (W): 406 mm 533 mm 610 mm 762 mm

Height (mm) (H): 1980 mm 2040 mm 2230 mm 2170 mm

(W)

660 mm

1340 mm

(H)

8 Installation & Operation Manual Copyright © Puretec Pty Ltd 2022

Operating Pressure Min/Max: 138 -862 kPa

Operating Temperature Min/Max: 0 - 40 °C (protect from freezing)

Electrical Connection: 240V / 50 Hz

Inlet/outlet Connection: 2" BSP

Drain: 1"

Brine: 1" BSP

Kit Type Part no. Description Qty

Tank Kit

(WTP2460-K)

WTP2460 Pressure Tank with Base (16x65) 1

WTV3040 Pressure Tank UV Collar Shield 1

WTD3320 Riser Pipe, 50mm PVC Grey (pre-installed) 2m

WTD3000 Top Mount 50mm, suits 14-16" Tanks (pre-installed) 1

Brine Tank & Filter

Kit

(WTV7100-K)

WTV5135 Transformer & Lead, suits Auto Valve 1

WTV7200 2CI Valve Cover 1

WTV5180 Spanner, suits E1, E3, NTS Systems 1

WTD3100 Top Screen Distributor Stack 1

WTV7100 2CI Soener Valve & Flow Meter 1

WTB2230 Brink Tank 1

WTV7370 Brine Connector 1" BSPM x 1" Barb (pre-installed - 1 on

the valve the other one on the brine tank)

2

WTV7365-2 1" Brine Hose 2m

WTV7360 Herbie Clip, Nylon, Black, N Size 2

DLFC Kit

(WTV-DLFC11)

WTV5340 Washer for DLFC, 42lpm, 1" (pre-installed) 1

WTV7330 1" Drain Line Flow Connector 1

Media Kit WTM7550-15L Multi-media High Performance Medium 15L 2

WTM4400-25B Resin Cation Soening 25B 4

Instruction Kit

(WTI-SOL110)

LBL-METALLICBLANK Metallic Silver Model Label (60x100) 1

UG-SOL-2CI Commercial 2CI WTS User Guide (CFS/IRS/IRX/SFS) 1

WTV1600 Media Funnel 1

WTV5595 Injector 4lpm Suits 2CI 18" Soener 1

SOL110-2CI Model Information

System Inclusions - Kits & Components

Specifications

Vessel Media Filling Order

1st 2nd

2 x WTM7550-15L 4 x WTM4400-25B

Model Information

9Copyright © Puretec Pty Ltd 2022 SOL-2CI Commercial Series User Guide

Operating Pressure Min/Max: 138 -862 kPa

Operating Temperature Min/Max: 0 - 40 °C (protect from freezing)

Electrical Connection: 240V / 50 Hz

Inlet/outlet Connection: 2" BSP

Drain: 1"

Brine: 1" BSP

Kit Type Part no. Description Qty

Tank Kit

(WTP2600-K)

WTP2600 Pressure Tank with Base (21x62) 1

WTV3040 Pressure Tank UV Collar Shield 1

WTD3320 Riser Pipe, 50mm PVC Grey (pre-installed) 2m

WTD3010 Top Mount 50mm, suits 18-24" Tanks (pre-installed) 1

Brine Tank & Filter

Kit

(WTV7100-K)

WTV5135 Transformer & Lead, suits Auto Valve 1

WTV7200 2CI Valve Cover 1

WTV5180 Spanner, suits E1, E3, NTS Systems 1

WTD3100 Top Screen Distributor Stack 1

WTV7100 2CI Soener Valve & Flow Meter 1

WTB2230 Brink Tank 1

WTV7370 Brine Connector 1" BSPM x 1" Barb (pre-installed - 1 on

the valve the other one on the brine tank)

2

WTV7365-2 1" Brine Hose 2m

WTV7360 Herbie Clip, Nylon, Black, N Size 2

DLFC Kit

(WTV-DLFC15)

WTV7350 Washer for DLFC, 57lpm, 1" (pre-installed) 1

WTV7330 1" Drain Line Flow Connector 1

Media Kit WTM7550-15L Multi-media High Performance Medium 15L 2

WTM4400-25B Resin Cation Soening 25L Bag 7

Instruction &

Injector Kit

(WTI-SOL160)

LBL-METALLICBLANK Metallic Silver Model Label (60x100) 1

UG-SOL-2CI Commercial 2CI WTS User Guide (CFS/IRS/IRX/SFS) 1

WTV1600 Media Funnel 1

WTV5600 Injector 6lpm Suits 2CI 21" Soener 1

SOL160-2CI Model Information

System Inclusions - Kits & Components

Specifications

Vessel Media Filling Order

1st 2nd

2 x WTM7550-15L 7 x WTM4400-25B

Model Information

10 Installation & Operation Manual Copyright © Puretec Pty Ltd 2022

Operating Pressure Min/Max: 138 -862 kPa

Operating Temperature Min/Max: 0 - 40 °C (protect from freezing)

Electrical Connection: 240V / 50 Hz

Inlet/outlet Connection: 2" BSP

Drain: 1"

Brine: 1" BSP

Kit Type Part no. Description Qty

Tank Kit

(WTP2600-K)

WTP2600 Pressure Tank with Base (21x62) 1

WTV3040 Pressure Tank UV Collar Shield 1

WTD3320 Riser Pipe, 50mm PVC Grey (pre-installed) 2m

WTD3010 Top Mount 50mm, suits 18-24" Tanks (pre-installed) 1

Brine Tank & Filter

Kit

(WTV7100-K)

WTV5135 Transformer & Lead, suits Auto Valve 1

WTV7200 2CI Valve Cover 1

WTV5180 Spanner, suits E1, E3, NTS Systems 1

WTD3100 Top Screen Distributor Stack 1

WTV7100 2CI Soener Valve & Flow Meter 1

WTB2230 Brink Tank 1

WTV7370 Brine Connector 1" BSPM x 1" Barb (pre-installed - 1 on

the valve the other one on the brine tank)

2

WTV7365-2 1" Brine Hose 2m

WTV7360 Herbie Clip, Nylon, Black, N Size 2

DLFC Kit

(WTV-DLFC15)

WTV7350 Washer for DLFC, 57lpm, 1" (pre-installed) 1

WTV7330 1" Drain Line Flow Connector 1

Media Kit WTM7550-15L Multi-media High Performance Medium 15L 3

WTM4400-25B Resin Cation Soening 25L Bag 10

Instruction &

Injector Kit

(WTI-SOL270)

LBL-METALLICBLANK Metallic Silver Model Label (60x100) 1

UG-SOL-2CI Commercial 2CI WTS User Guide (CFS/IRS/IRX/SFS) 1

WTV1600 Media Funnel 1

WTV5605 Injector 8.5lpm Suits 2CI 24" Soener 1

SOL270-2CI Model Information

System Inclusions - Kits & Components

Specifications

Vessel Media Filling Order

1st 2nd

3 x WTM7550-15L 10 x WTM4400-25B

Model Information

11Copyright © Puretec Pty Ltd 2022 SOL-2CI Commercial Series User Guide

SOL380-2CI Model Information

System Inclusions - Kits & Components

Specifications

Operating Pressure Min/Max: 138 -862 kPa

Operating Temperature Min/Max: 0 - 40 °C (protect from freezing)

Electrical Connection: 240V / 50 Hz

Inlet/outlet Connection: 2" BSP

Drain: 1"

Brine: 1" BSP

Kit Type Part no. Description Qty

Tank Kit

(WTP2680-K)

WTP2680 Pressure Tank with Base (30x72) 1

WTV3040 Pressure Tank UV Collar Shield 1

WTD3320 Riser Pipe, 50mm PVC Grey (pre-installed) 2m

WTD3020 Top Mount 50mm, suits 30" Tanks (pre-installed) 1

Brine Tank & Filter

Kit

(WTV7100-K)

WTV5135 Transformer & Lead, suits Auto Valve 1

WTV7200 2CI Valve Cover 1

WTV5180 Spanner, suits E1, E3, NTS Systems 1

WTD3100 Top Screen Distributor Stack 1

WTV7100 2CI Soener Valve & Flow Meter 1

WTB2230 Brink Tank 1

WTV7370 Brine Connector 1" BSPM x 1" Barb (pre-installed - 1 on

the valve the other one on the brine tank)

2

WTV7365-2 1" Brine Hose 2m

WTV7360 Herbie Clip, Nylon, Black, N Size 2

DLFC Kit

(WTV-DLFC25)

WTV5395 Washer for DLFC, 95lpm, 1" (pre-installed) 1

WTV7330 1" Drain Line Flow Connector 1

Media Kit WTM7550-15L Multi-media High Performance Medium 15L 4

WTM4400-25B Resin Cation Soening 25L Bag 15

Instruction &

Injector Kit

(WTI-SOL380)

LBL-METALLICBLANK Metallic Silver Model Label (60x100) 1

UG-SOL-2CI Commercial 2CI WTS User Guide (CFS/IRS/IRX/SFS) 1

WTV1600 Media Funnel 1

WTV5610 Injector 12lpm Suits 2CI 30" Soener 1

Vessel Media Filling Order

1st 2nd

4 x WTM7550-15L 15 x WTM4400-25B

Model Information

12 Installation & Operation Manual Copyright © Puretec Pty Ltd 2022

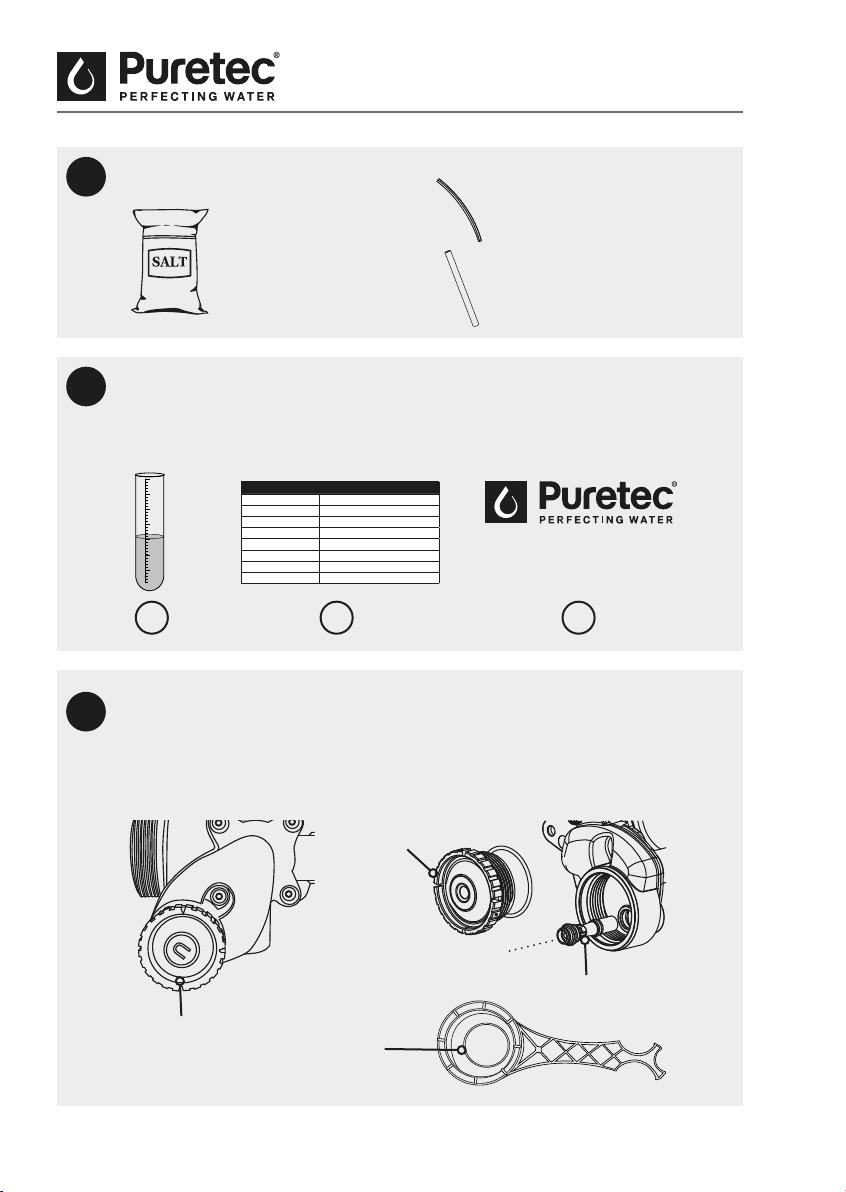

Exploded Diagram

Exploded Diagram

Riser Pipe & Top Mount

(pre-installed)

Transformer Injector

Drain Line Flow

Connector

Spanner

Brine Hose

Brine

Tank

Pressure Tank

UV Shield

Top Screen

Valve

Flow Meter

(pre-installed

onto valve)

Valve Cover

Brine Connector

(pre-installed

on valve)

Herbie Clip

Brine Connector

(pre-installed

on brine tank)

Herbie

Clip

13Copyright © Puretec Pty Ltd 2022 SOL-2CI Commercial Series User Guide

Parts Identification

Outlet 2"

Control Panel

Inlet 2"

Diagram Identification

Brine 1”

Drain1"

Valve connection is 1.5" BSP

& outlet from the DLFC is 1"

Outlet Pressure Gauge Port

¼" (capped off)

Inlet Pressure Gauge Port

¼" (capped off)

Installation Procedure

Unpack the Equipment

Ensure all parts are present and have not been damaged in transport. You should have:

1

User Guide

AutomaticVolume Based Water Softening Appliance

SOL-2CI Commercial Series

Forcorrect operation & installation it is essential to observe these instructions.

DEC2019

Brine Tank & Valve Kit

Instruction &

Injection Kit

Media

Tank Kit DLFC Kit

Note: For a detailed part listing of

kit components see individual model

specifications on pages 8-11.

14 Installation & Operation Manual Copyright © Puretec Pty Ltd 2022

Installation Procedure

1" Tubing for drain

(refer to page 17)

Bag of Salt (refer to page

16 for the type of salt to

be used)

Testing & Analysis

Ensure water has been tested, Input values into Table on page 4 and the

analysis has been inspected by Puretec.

3

Water Analysis Information

Hardness ___________ ppm / mg/L

Iron ___________ ppm / mg/L

Manganese ___________ ppm / mg/L

pH ___________

TDS (Total Dissolved Salts) ___________ ppm / mg/L

Conductivity ___________ EC / uS/cm

Chloride ___________ ppm / mg/L

Sodium ___________ ppm / mg/L

130

0.3

0.1

7

275

404

121

96

✓✓

Customer Service Helpline

1300 140 140 (AU) 0800 130 140 (NZ)

✓

Extra Items Required

2

1" Polypipe for overflow

(refer to page 17)

Install the Injector

Before attaching the valve the injector needs to be installed. Remove the injector from

the Instruction & Injector Kit and undo the injector cap on the valve using the spanner

provided. Insert the Injector and replace the injector cap, tightening with the spanner.

4

Injector Cap

Spanner

Injector

Injector Cap

& O-ring

15Copyright © Puretec Pty Ltd 2022 SOL-2CI Commercial Series User Guide

Installation Procedure

Position the Soener System on a Level Surface

Environmental conditions

Operating temperature: 0 - 40 °C

(protect from freezing)

Water conditions

Temperature: 0 - 50 °C

Pressure: 138 -862* kPa

*Where line pressure exceeds 500 kPa, an approved pressure limiting

device must be installed to comply with Australian & New Zealand

Plumbing Standards. (Ref. AS/NZS 3500.1:2021, Clause 3.3.4).

5

Media Installation

The Media has been shipped separately to avoid damage in transit.

The length of the internal riser pipe is pre-set and does not need adjustment.

1. Position the system on a flat surface close to a drain or a properly

trapped outlet, in a position where the system can service all lines

requiring treated water. The system should be placed far enough

away from any water heaters to avoid any hot water backflow into

the system. A weatherproof power point and surge protector is

recommended.

2. Plug or cover the top end of the riser pipe in the tank making sure no

media can enter the tube.

3. Ensure that the riser pipe is sitting in the cradle at the base of the tank.

Then using a wide mouth funnel, place the media in the tank as per the

filling order on the individual model specification pages.

4. CRITICAL STEP: Insert the Distributor into the control valve and twist

firmly until it "clicks" into place (see page 12 diagram).

5. Remove the plug or cover from the riser pipe making sure you do not li

the riser pipe. Top up tank with water. Screw valve onto the tank (hand

tight is usually sufficient), making sure the distributor tube is properly

inserted into the valve.

6

16 Installation & Operation Manual Copyright © Puretec Pty Ltd 2022

Installation Procedure

Connecting the Drain Line

Locate the drain line flow controller (see page 12 for identification and attach to the

tubing (tubing not supplied) from the valve to the drain. Ensure the drain line is not

kinked. The line must not travel more than 2.4m up and no more than 6m long from

the valve, otherwise an increase of the diameter of the drain line will be required.

Connect drain and overflow to sewer or other approved salty water disposal point as

approved by your local authority.

8

Connecting the Sorol System

Connect the Sorol system to main plumbing. Do not solder brass adapters while they

are inserted in the control module.

7

FOLLOW LOCAL

PLUMBING CODES

1"DRAIN

BRINE

17Copyright © Puretec Pty Ltd 2022 SOL-2CI Commercial Series User Guide

Programming

6.1 Plug into an uninterrupted electrical outlet.

Note: All electrical connections must be connected accordingly to local codes.

6.2 Proceed to ‘Programming’ section

12

Connecting the Overflow

Connecting Brine Draw Line Connector

10

9

Connect polypipe onto the 1” overflow

fitting (polypipe not supplied) and run

the line to the drain. Do not connect

the overflow into the drain line, as it

must be a direct and separate line to

the drain. Allow an air gap as per the

drain line. Make sure the drain is not

higher than the overflow.

Locate the Brine Draw Line Connector. Push one end of the brine hose onto the

connector in the brine tank and the other end onto the connnector on the valve.

Secure the hose with the supplied herbie clips.

Note: The hose fits very firmly on the connectors, we suggest warming up the hose

before pushing onto the connectors.

BRINE

Installation Procedure

Connecting The Flow Meter

Connect the flow meter to the 3 pin

port connection, located on the bottom

right hand side of the PC Board.

Note: Flow meter MUST be installed

on the outlet side of the valve, and is

recommended to be aer any add-

on components (e.g. No Hard Water

Bypass).

11

UP DOWNDOWN

SET

CLOCK NEXT REGEN

18 Installation & Operation Manual Copyright © Puretec Pty Ltd 2022

Valve & DP Programming

Valve Configuration and Optional DP Switch Programming

CRITICAL STEP, THIS MUST BE DONE PRIOR TO SETUP PROGRAMMING.

1. Pres NEXT and simultaneously for 5 seconds and

release. Then press NEXT and simultaneously for 5

seconds and release.

Note: Press REGEN at anytime in the programming

sequence to return to the previous step.

2. Preset to default. Press NEXT to go to step 3.

3. Preset to default. Press NEXT to go to step 4.

4. Preset to "oFF" (default) unless other modules are in-

stalled (e.g. no hard water bypass) Refer to your module

documentation for details.

Press NEXT to go to step 5.

19Copyright © Puretec Pty Ltd 2022 SOL-2CI Commercial Series User Guide

5. Allows selection of one of the following :

• An outside signal to initiate a regeneration; or

• An outside signal to prevent or delay regeneration.

Selection only matters if a connection is made to the two

pin connector labelled DP SWITCH located on the printed

circut board.

• oFF (default) : Feature not used.

Note: In a twin alternating system each control must have

a separate dP signal or dP switch. One dP signal or one dP

switch cannot be used for both controls.

• dPon0: If the dP switch is closed for an accumulative time

of 2 minutes, a regeneration will be signalled to the unit.

• dPdEL: If the switch is closed for an accumulative time

of 2 minutes a regeneration will occur at the scheduled

delayed regeneration time. Once the dP switch is triggered

the PC board will display REGEN TODAY and switch tanks

immediately. At the delayed regeneration time, the triggered

unit will then regenerate.

• HoLd: If the dP switch is closed a regeneration will be

prevented from occurring while there is switch closure.

Press NEXT to go to step 6.

6. Preset to default. ( or buttons can be used to set hard-

ness) Press NEXT to go to step 7.

7. Preset to default. Press NEXT to go to step 8.

Valve & DP Programming

20 Installation & Operation Manual Copyright © Puretec Pty Ltd 2022

8. Preset to default. Press NEXT to go to step 9.

9. Using or buttons, select 3. Press NEXT to go to step

10.

10. Using or buttons, select 4. Press NEXT to go to step

11.

11. Using or buttons, select 5 End. Press NEXT to go to

step 12.

12. Preset to default. Press NEXT to return to normal mode.

Valve & DP Programming

RETURN TO NORMAL

MODE

Flashes between these screens.

This manual suits for next models

4

Table of contents

Other Watermark Water Dispenser manuals

Popular Water Dispenser manuals by other brands

IBC Water

IBC Water AST0715MP-960 Installation & operating instructions

Lancaster Water Treatment

Lancaster Water Treatment X FACTOR LX15 Series Installation, operating and service manual

Elkay

Elkay EMABF8 Series Installation & use manual

Oasis

Oasis Osmosis Home installation manual

Monarch Water

Monarch Water ULTIMATE MINI AQUA HE install guide

Haier

Haier HLM-109B instruction manual