4

EN

1 Safety instructions

1.1 General safety instructions

This product was manufactured according to all

recognised regulations and technical standards

and complied with the applicable legal requirements

when it was put into circulation.

Nevertheless, it can pose a risk of personal injury

or property damage if you do not observe this

chapter and the safety instructions throughout this

documentation.

Read this documentation carefully and in its en-

tirety before working with the product.

This documentation must be kept accessible to

all users at all times.

Always hand over the product to third parties to-

gether with the full documentation.

Follow all of the instructions in relation to the

proper handling of the product.

If you detect damage to the product or the mains

supply, stop its operation and notify a service

technician immediately.

Use only accessories, spare parts and con-

sumable materials that have been approved by

BWT.

Adhere to the environmental and operating con-

Use your personal protective equipment. It en-

sures your safety and protects you from injury.

Perform only tasks that are described in these

operating instructions or that you have been

trained to do by BWT.

Perform all tasks in compliance with all applica-

ble standards and provisions.

Instruct the operator in the function and opera-

tion of the product.

Instruct the operator in the maintenance of the

product.

Instruct the operator in relation to potential dan-

gers that may arise while operating the product.

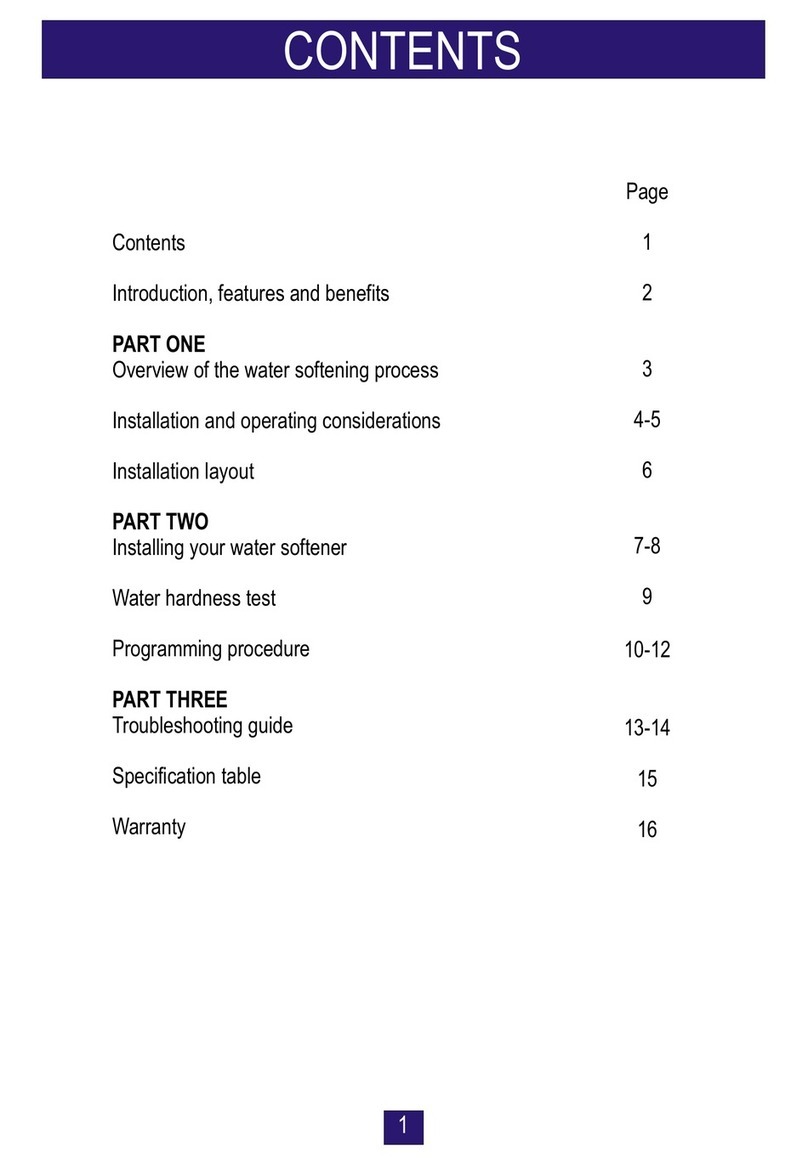

1.2 Scope of the documentation

This documentation applies exclusively to the

product the production number of which listed

in chapter 12, “Technical data”.

This documentation is intended for operators,

installers without training from BWT, installers with

training from BWT (e.g. drinking water specialists),

and BWT service technicians.

This documentation contains important information

up, operating, using, maintaining, and disassem-

bling the product, and for correcting simple faults

independently.

Read this documentation in full before working with

the product. Pay particular attention to the chapter

1.3 Personnel qualications

The installation work described in these instructions

requires basic knowledge of mechanics, hydraulics

and electrical systems as well as knowledge of the

corresponding specialist terms.

To ensure that the device is installed safely, this work

specialist.

A qualied specialist is someone with specialist

training, knowledge and experience as well as

knowledge of the applicable regulations allowing

them to assess the work assigned to them, identify

potential risks, and take suitable safety measures. A

specialist regulations.

A trained person is someone who has been

entrusted to them and the potential dangers of

improper conduct and, if necessary, trained and

instructed on the necessary protective equipment

and protective measures.