i

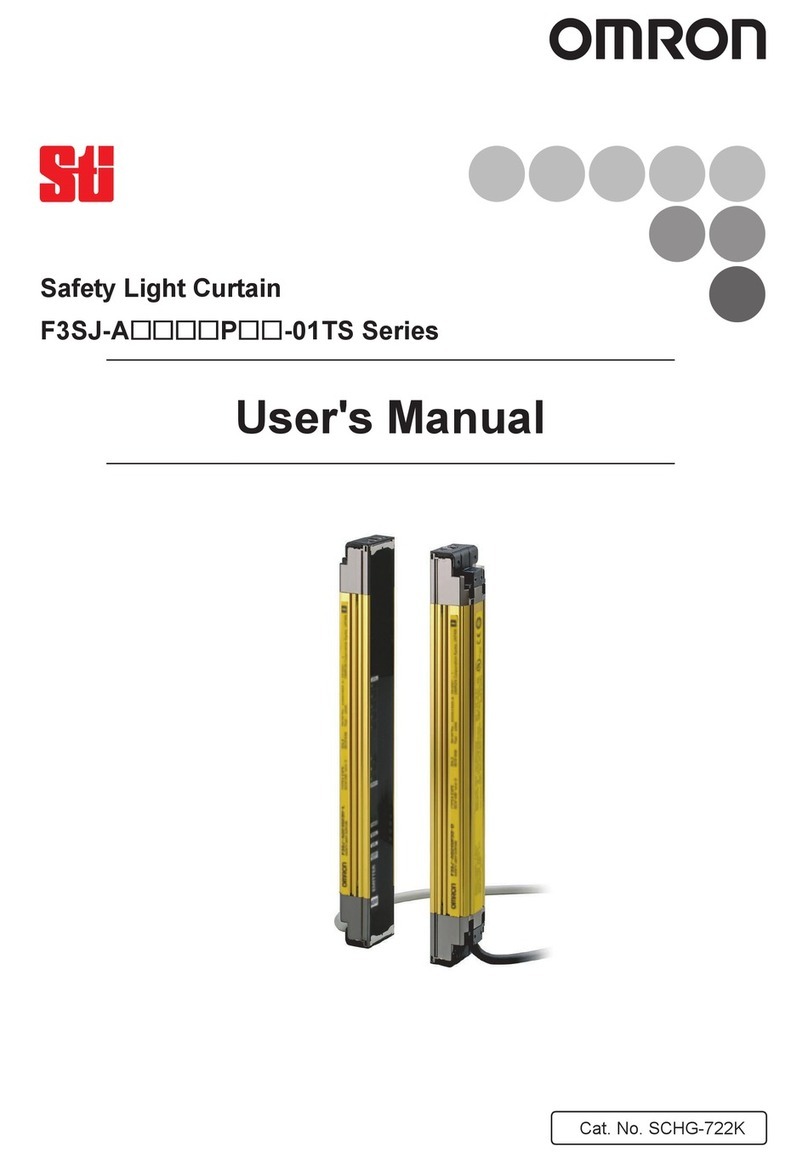

F3SJ-A

User’s Manual

Introduction

Introduction

E

LegislationandStandards

1. Application of a F3SJ-A sensor alone cannot receive type approval provided by Article 44-2 of the Labour

Safety and Health Law of Japan. It is necessary to apply it in a system. Therefore, when using the F3SJ-A

in Japan as a "safety system for pressing or shearing machines" prescribed in Article 42 of that law, the

system must receive type approval.

2. The F3SJ-A is electro-sensitive protective equipment (ESPE) in accordance with European Union (EU)

Machinery Directive Index Annex IV, B, Safety Components, Item 1.

3. The F3SJ-A complies with the following legislation and standards:

(1) EU legislation

Machinery Directive 98/37/EC

EMC Directive 89/336/EEC

(2) European standards

EN61496-1 (Type 4 ESPE), prEN61496-2 (Type 4 AOPD), EN61508-1 through -7 (SIL3)

(3) International standards

IEC61496-1 (Type 4 ESPE), IEC61496-2 (Type 4 AOPD), IEC61508-1 through -7 (SIL3)

(4)JIS standards

JIS B 9704-1 (Type 4 ESPE), JIS B 9704-2 (Type 4 AOPD)

(5) North American Standards:

UL61496-1(Type 4 ESPE), UL61496-2(Type 4 AOPD), UL508, UL1998, CAN/CSA 22.2 No.14, CAN/

CSA 22.2 No.0.8

4.

The F3SJ-A received the following approvals from the EU accredited body, TÜV SÜD Product Service GmbH:

•EC Type-Examination in accordance with the EU Machinery Directive, Type 4 ESPE (EN61496-1),

Type 4 AOPD (prEN61496-2)

•EMC Competent Body Certificate (Power supply for test: OMRON S82K)

•TÜV SÜD Product Service Type Approval, Type 4 ESPE (EN61496-1), Type 4 AOPD (prEN61496-2),

SIL1, 2, 3 (EN61508-1 through -7), Application: EN954-1 Category B,1,2,3,4

5. The F3SJ-A received the certificates of UL listing for US and Canadian safety standards from the Third

Party Assessment Body UL.

•Both are: Type 4 ESPE (UL61496-1), Type 4 AOPD (UL61496-2)

6. The F3SJ-A is designed according to the standards listed below. To make sure that the final system

complies with the following standards and regulations, you are asked to design and use it in accordance

with all other related standards, laws, and regulations. If you have any questions, consult with specialized

organizations such as the body responsible for prescribing and/or enforcing machinery safety regulations

in the location where the equipment is to be used.

•European Standards: EN415-4, EN692, EN693

•U.S. Occupational Safety and Health Standards: OSHA 29 CFR 1910.212

•U.S. Occupational Safety and Health Standards: OSHA 29 CFR 1910.217

•American National Standards: ANSI B11.1 to B11.19

•American National Standards: ANSI/RIA 15.06

•Canadian Standards Association CSA Z142, Z432, Z434

•SEMI Standards SEMI S2

•Ministry of Health, Labour and Welfare "Guidelines for Comprehensive Safety Standards of

Machinery", Standard Bureau's Notification No. 501 dated June 1, 2001.

* For date of effect for these standards, see Related Standards.

Related Standards p.126

Legislation and Standards

Courtesy of CMA/Flodyne/Hydradyne ▪Motion Control ▪Hydraulic ▪Pneumatic ▪Electrical ▪Mechanical ▪(800) 426-5480 ▪www.cmafh.com