4003_5001_D02 Page 2 of 35

CONTENTS Page

1. GENERAL DESCRIPTION ......................................................................................... 4

2. SPECIFICATIONS ................................................................................................... 5

2.1. GENERAL .......................................................................................................... 5

2.2. STANDARD OUTPUTS ......................................................................................... 5

2.3. OPTION OUTPUTS.............................................................................................. 5

2.3.1. LoRa Radio Modem ........................................................................................ 5

3. RULES FOR SAFE OPERATION ................................................................................. 6

4. OPERATION .......................................................................................................... 7

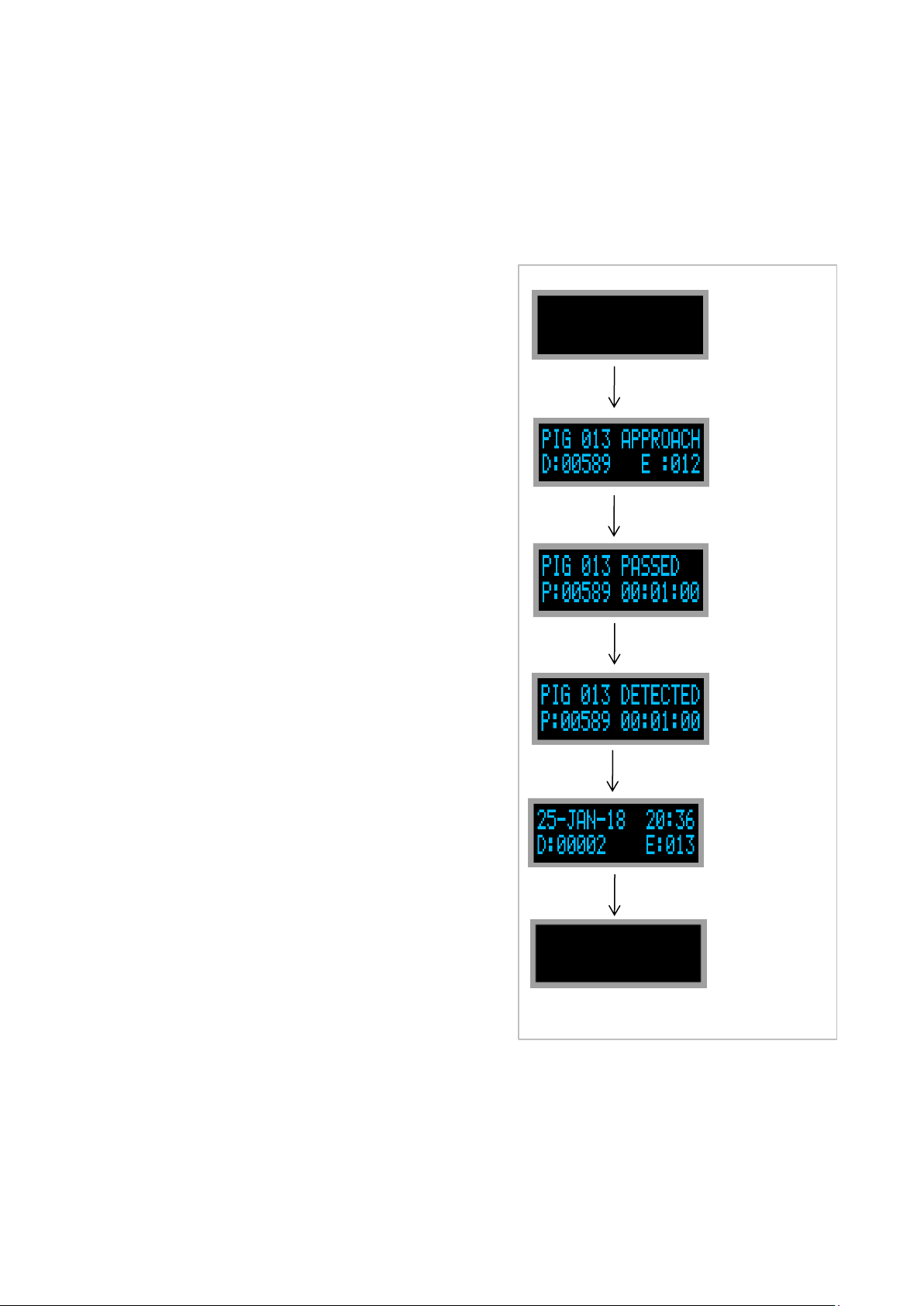

4.1. TURNING ON..................................................................................................... 7

4.2. STABILISATION................................................................................................. 8

4.3. LISTENING ....................................................................................................... 8

4.4. DETECTION MODE ............................................................................................. 9

4.4.1. PIG PASSED .................................................................................................. 9

4.4.2. PIG DETECTION ONLY .................................................................................... 9

4.4.3. DETECTION DELAY....................................................................................... 10

4.5. SINGLE BUTTON MENU INTERFACE.................................................................... 11

4.5.1. VIEW EVENTS ............................................................................................. 13

4.5.2. COPY EVENTS TO SD CARD........................................................................... 13

4.5.3. DELETE ALL EVENTS .................................................................................... 13

4.5.4. SHUTDOWN ................................................................................................ 13

4.5.5. DATE.......................................................................................................... 14

4.5.6. TIME .......................................................................................................... 14

4.5.7. THRESHOLD................................................................................................ 14

4.5.8. POWER MODE ............................................................................................. 14

4.5.9. STABILISATION DELAY ................................................................................. 14

4.5.10. DETECTION DELAY....................................................................................... 14

4.5.11. DETECTION METHOD ................................................................................... 14

4.5.12. AUTO POWER OFF........................................................................................ 15

4.5.13. RELAY LOGIC .............................................................................................. 15

4.5.14. SENSOR SELECT.......................................................................................... 15

4.5.15. SENSOR OUTPUT ......................................................................................... 15

4.5.16. LED FLASH.................................................................................................. 15

4.5.17. BLUETOOTH ................................................................................................ 16

4.5.18. INTERFACE ................................................................................................. 16

4.5.19. RS485 BAUD RATE....................................................................................... 16

4.5.20. RS485 PARITY ............................................................................................. 16

4.5.21. MODBUS ADDRESS ...................................................................................... 16

4.5.22. SD LOG ...................................................................................................... 16

4.5.23. LANGUAGE.................................................................................................. 16

4.5.24. RESET TO FACTORY SETTINGS ...................................................................... 16

4.5.25. EXIT MENU ................................................................................................. 17

4.6. MODBUS RTU RS485 INTERFACE ....................................................................... 17

4.6.1. MODBUS REGISTER MAP .............................................................................. 17

4.7. EVENT LOGGING AND SD CARD ........................................................................ 20

4.7.1. EVENT LOGGING ......................................................................................... 20

4.7.2. SD CARD .................................................................................................... 20

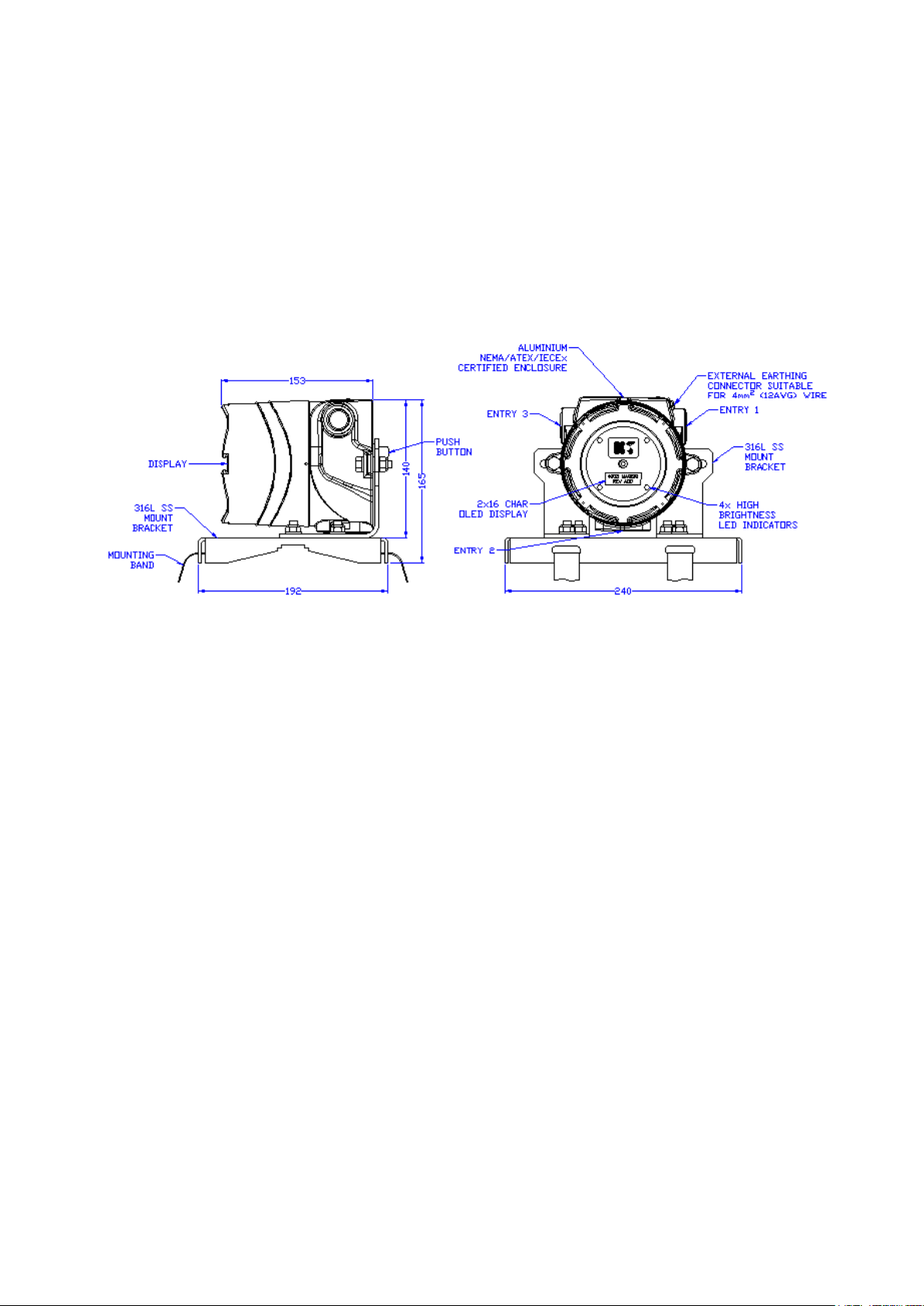

4.8. MOUNTING ..................................................................................................... 21

4.8.1. REMOTE SENSOR MOUNTING ........................................................................ 21

4.9. BATTERY REPLACEMENT ................................................................................... 22

4.10. EXTERNAL CONNECTIONS ................................................................................ 23

4.10.1. RELAY OUTPUT ............................................................................................ 24

4.10.2. CURRENT LOOP OUTPUT ............................................................................... 24

4.11. INTERNAL HEATER........................................................................................... 24

4.12. RTC BACKUP ................................................................................................... 25

4.13. LoRa .............................................................................................................. 26

4.14. RECOMMENDED MAGNET ARRANGEMENT ........................................................... 28

5. BLUETOOTH INTEGRATION ................................................................................... 29