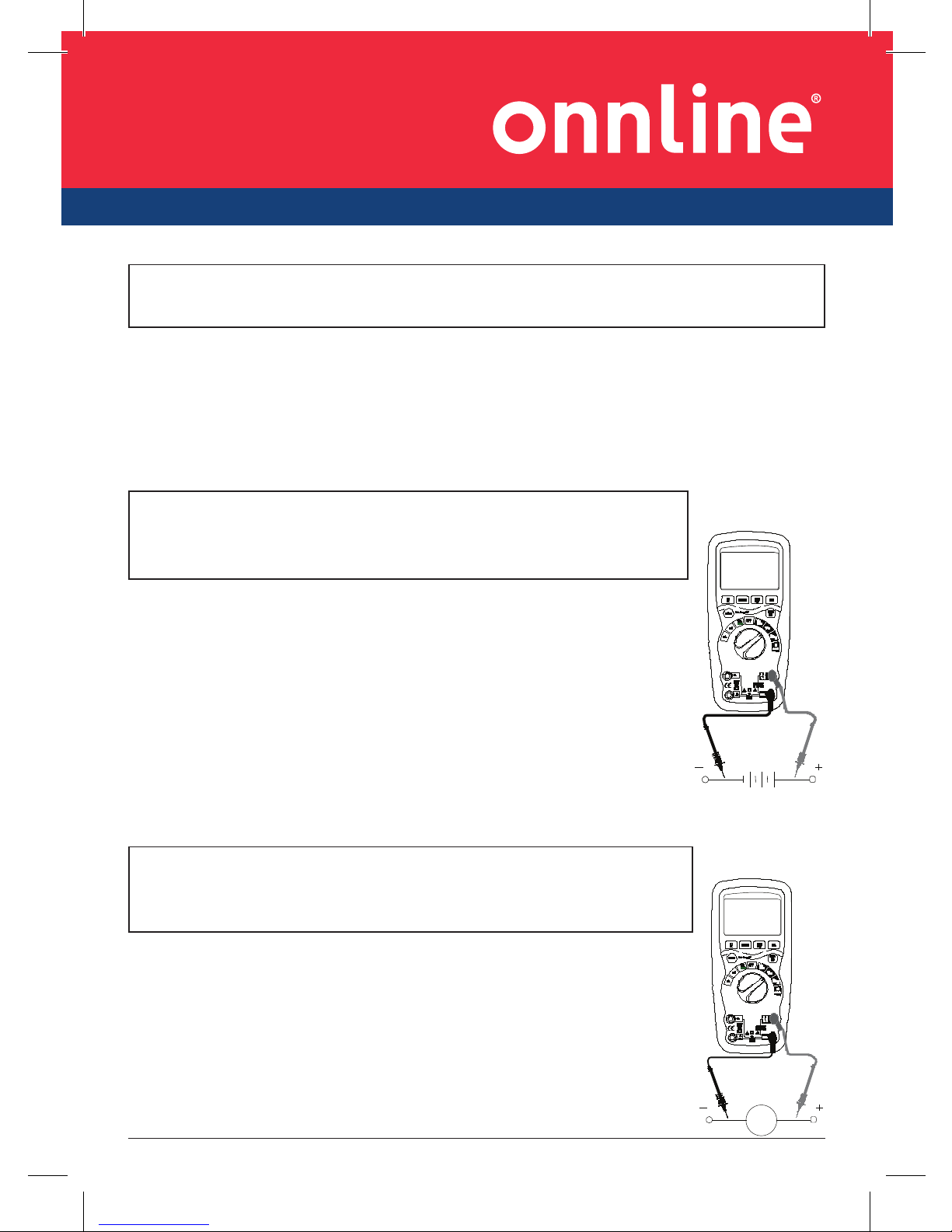

AC/DC CURRENT MEASUREMENTS

1. Insert the black test lead banana plug into the negative COM

jack.

2. For current measurements up to 6000µA AC/DC, set the

function switch to the µA position and insert the red test lead

banana plug into the µA/mA jack,press mode button to select

AC or DC.

3. For current measurements up to 600mA DC, set the function

switch to the mA position and insert the red test lead banana

plug into the µA/mA jack ,press mode button to select AC or

DC.

4. For current measurements up to 10A DC, set the function

switch to the 10A position and insert the red test lead banana

plug into the 10A jack, press mode button to select AC or DC.

5. Remove power from the circuit under test, then open up the

circuit at the point where you wish to measure current.

6. Touch the black test probe tip to the negative side of the circuit. Touch the red

test probe tip to the positive side of the circuit.

7. Apply power to the circuit and read the current in the display.

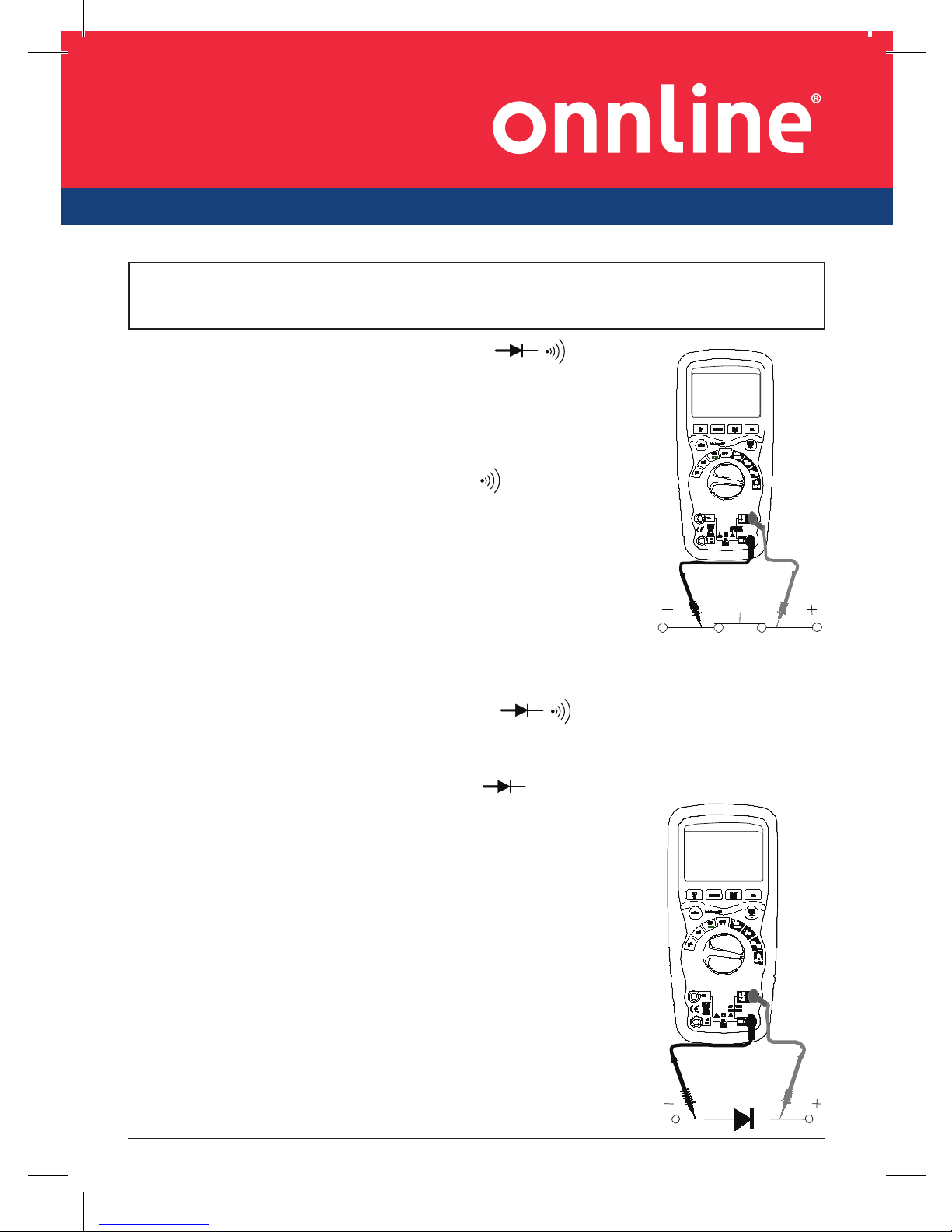

RESISTANCE MEASUREMENTS

1. Set the function switch to the Ω CAP position.

2. Insert the black test lead banana plug into the negative

COM jack. Insert the red test lead banana plug into the

positive Vjack.

3. Press the MODE button to indicate “Ω” on the display.

4. Touch the test probe tips across the circuit or part under test.

It is best to disconnect one side of the part under test so

the rest of the circuit will not interfere with the resistance

reading.

CAUTION: Do not make 10A current measurements for longer than 30

seconds. Exceeding 30 seconds may cause damage to the meter and/or the

test leads.

WARNING: To avoid electric shock, disconnect power to the

unit under test and discharge all capacitors before taking

any resistance measurements. Remove the batteries and

unplug the line cords.