8845A/8846A

Programmers Manual

ii

Installation Test for IEEE 488 Connections .................................................. 17

If Test Fails.................................................................................................... 17

How the Meter Processes Input ......................................................................... 18

Input Strings .................................................................................................. 18

Input Terminators .......................................................................................... 18

Typical IEEE 488 Input Strings..................................................................... 19

Sending Numeric Values to the Meter .......................................................... 19

Sending Command Strings to the Meter........................................................ 19

How the Meter Processes Output....................................................................... 21

Triggering Input................................................................................................. 21

Internal Triggering......................................................................................... 21

External Triggering ....................................................................................... 22

Service Requests (IEEE 488 Only) and Status Registers .................................. 22

Standard Event Status and Standard Event Status Enable Registers............. 23

Questionable Data Event Register and Questionable Data Enable Register . 24

Status Byte Register ...................................................................................... 25

Reading the Status Byte Register .................................................................. 25

Service Request Enable Register................................................................... 26

Supported SCPI Commands .............................................................................. 27

SCPI Command Summary ............................................................................ 27

SCPI Command Details................................................................................. 36

Using the MEASure? Command ................................................................... 37

Using the CONFigure Command .................................................................. 38

Using the READ? Command ........................................................................ 41

Using the INITiate Command ....................................................................... 41

Using the FETCh? Command ....................................................................... 41

Using the SENSe Subsystem to Configure the Meter ................................... 41

Programming for Math Operations................................................................ 50

Programming the Trigger System.................................................................. 54

Using System-Related Commands ................................................................ 57

Using Status Reporting Commands............................................................... 60

Calibration Commands.................................................................................. 62

Using RS-232/Ethernet Interface Commands ............................................... 64

Command Terminators.................................................................................. 65

Alternate Programming Language Compatibility ......................................... 66

FLUKE 45 Command Emulation Summary...................................................... 67

Computer Interface Command Set ................................................................ 67

IEEE 488 Capabilities and Common Commands.......................................... 67

Triggering Output.......................................................................................... 74

Using FlukeView Forms.................................................................................... 75

Introduction........................................................................................................ 77

Introduction........................................................................................................ 85

Incompatible Fluke 45 Commands .................................................................... 85

Dual Functions............................................................................................... 86

Reading Rates................................................................................................ 86

Ranges ........................................................................................................... 86

Introduction........................................................................................................ 87

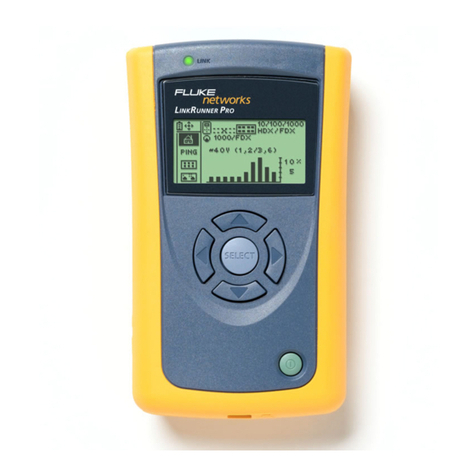

Your Meter and Your Network Administrator .................................................. 87

Network Primer.................................................................................................. 88

Physical Layer Wiring Schemes Supported by the Meter ............................. 88

Network Interconnection Devices ................................................................. 89

Basic Network Packet and Frame Contents .................................................. 89

IP Addresses and Segmented Networks ........................................................ 90

TCP/IP Protocol Stack................................................................................... 92