1. What is Included and Where to Start

The ADU200 ships complete with a 10' USB cable, and this User Manual.

A complete Windows SDK including DLL, programming language examples (MatLab, LabView, Visual C, Visual Basic,

.NET, Linux, Python, OSX etc.), and our AduHidtest software is available at:

www.ontrak.net/programming.htm

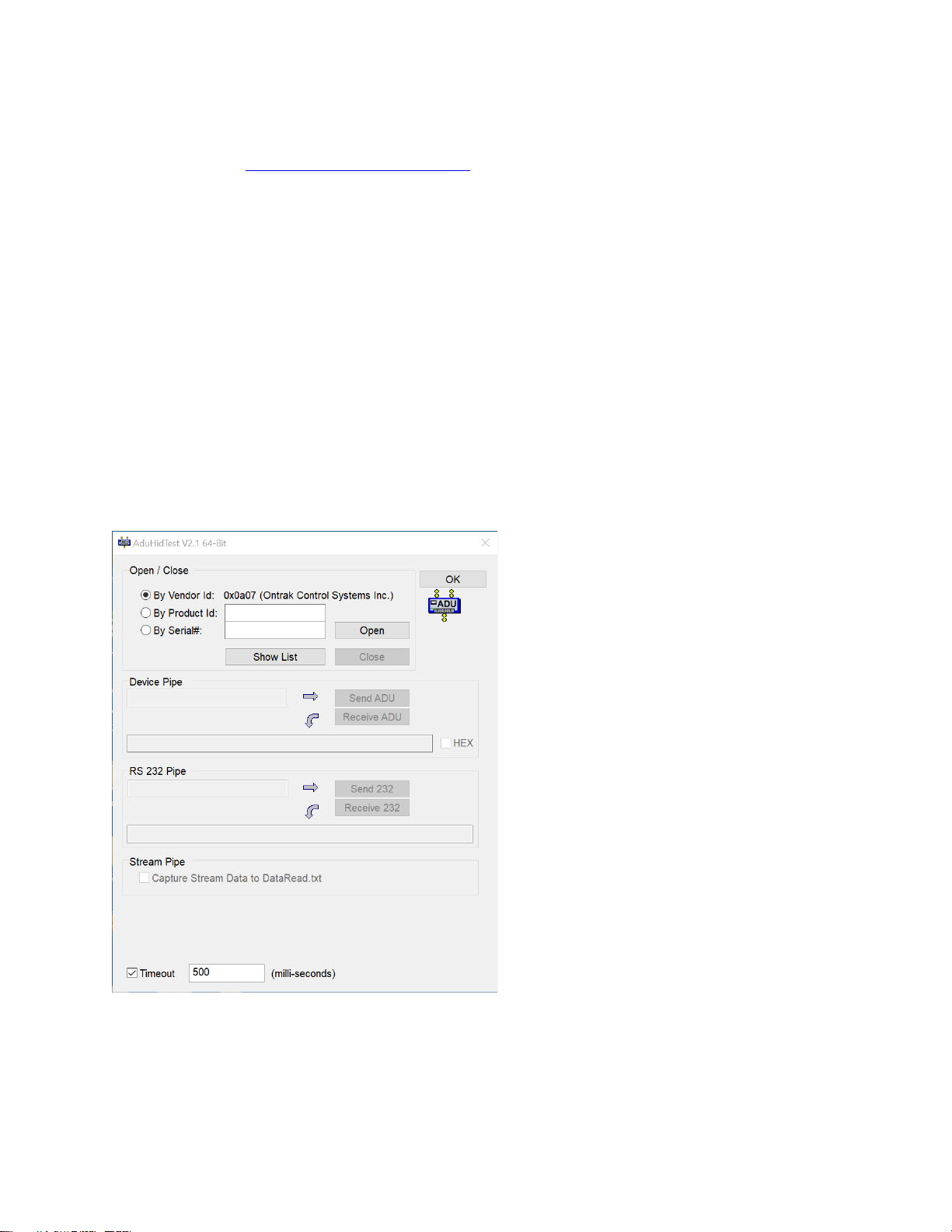

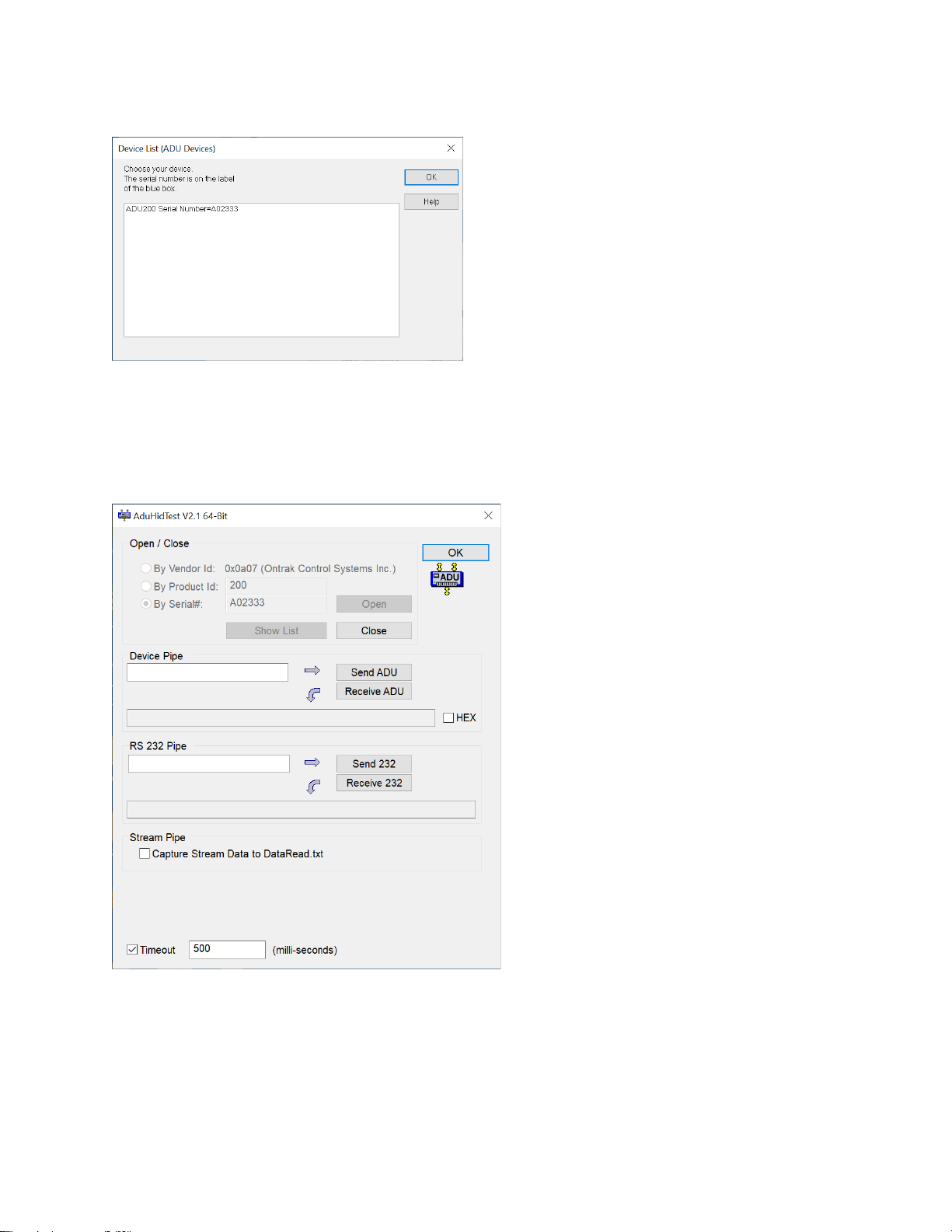

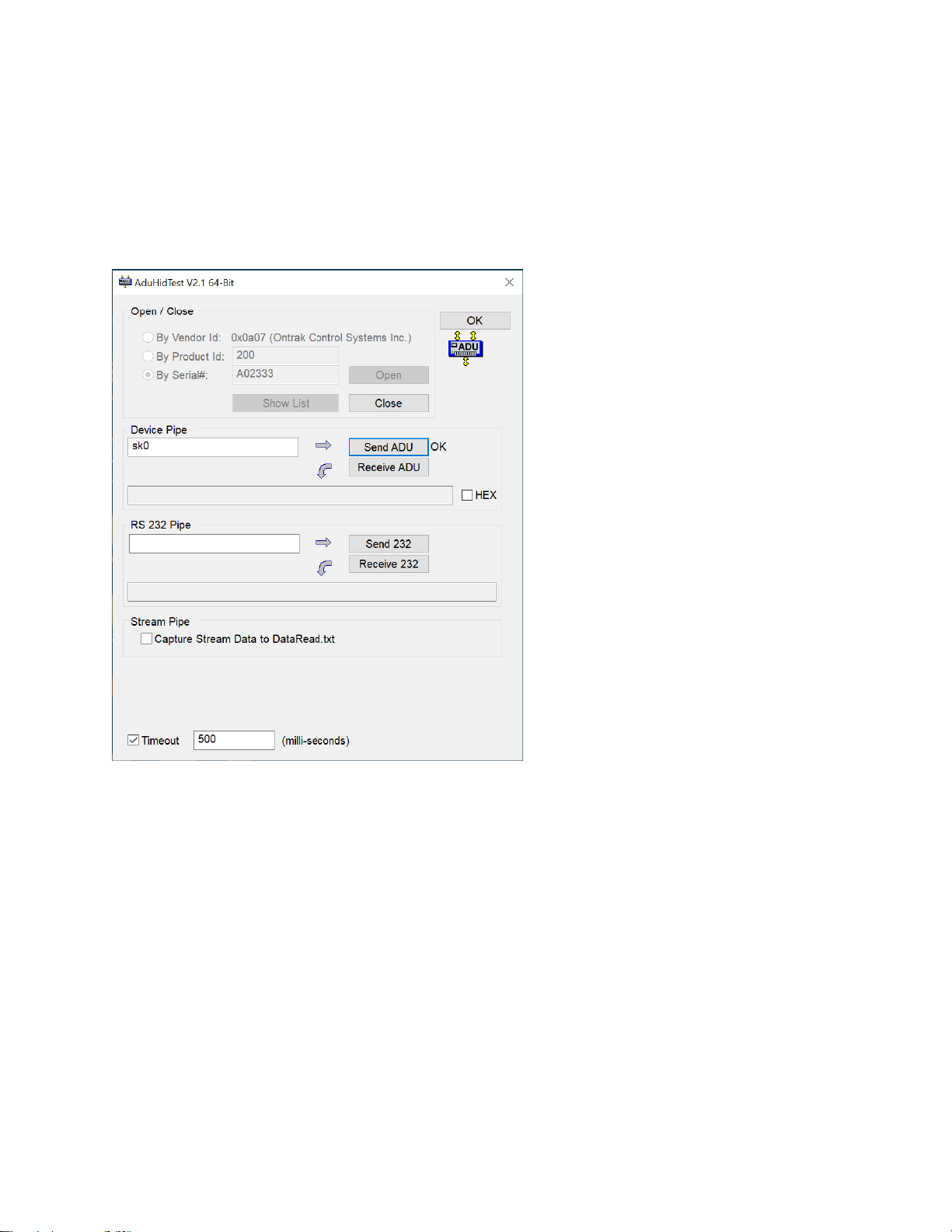

First time users should first review the ASCII command set for the ADU200 and then use AduHidTest USB test

software to become familiar with the command syntax, and the operation of the various features of the product.

Note: The AduHid DLL requires one of the following Windows operating systems, Windows XP, Windows 7, 8, 10 or

higher. The programming section of the website also contains examples for use with various other operating

systems, and provides details that allow use of the ADU200 without using the Windows based AduHid DLL.

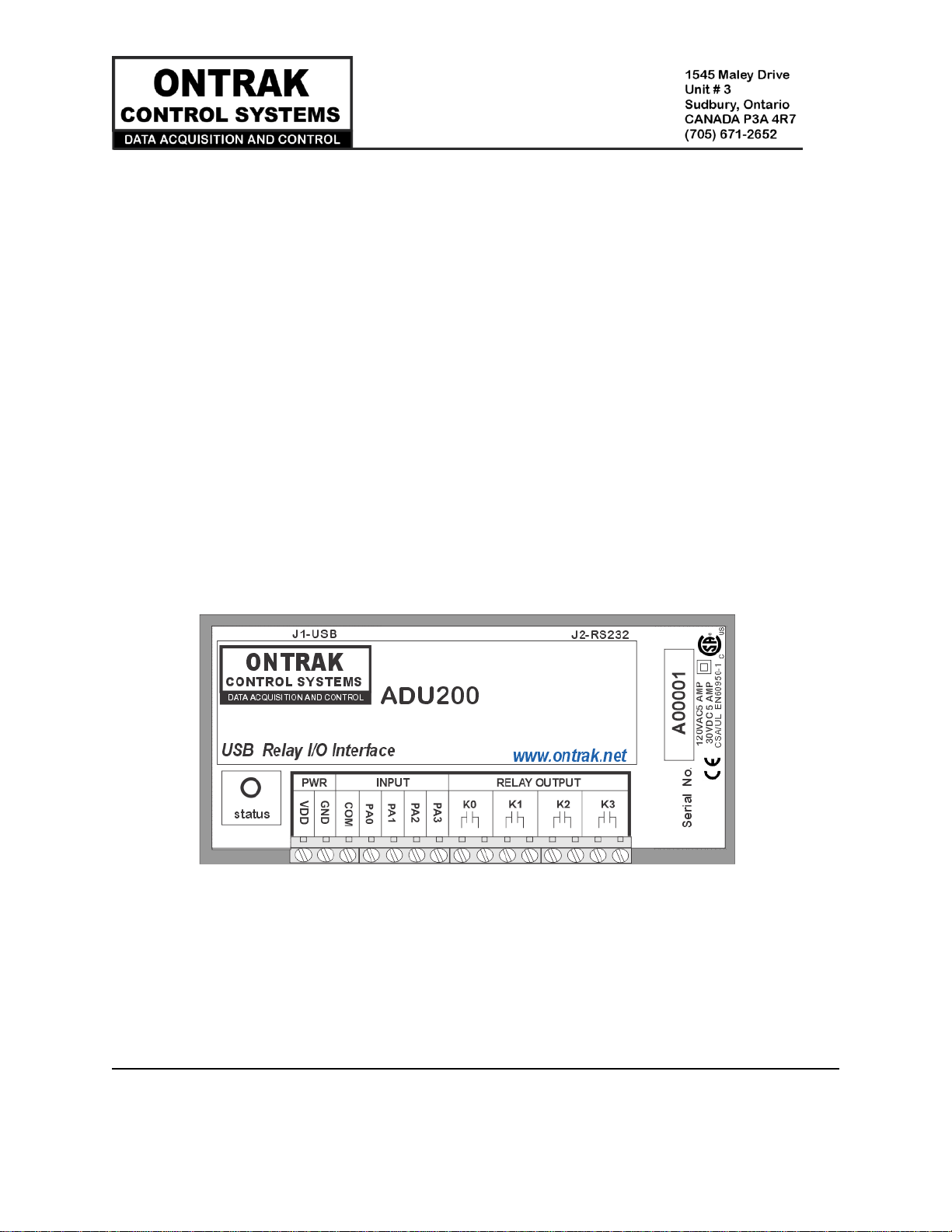

2. ADU200 Features

•Bus Powered, no external power supply required.

•Uses high quality Panasonic APAN3105 relays.

•4, N. O. Mechanical Relay outputs rated 5.0A @ 120VAC, 5.0A @ 30VDC

•4 Digital inputs suitable for contact or TTL Input, also accept up to 24VDC

•4, 16-bit event counters associated with digital Inputs.

•CSA/UL Certified, CE Marked

•High Retention USB connector.

•Bi-colour LED status indicator.

•High quality cage-clamp type terminal blocks.

•Uses standard HID drivers included with Windows 7,8,10 or higher.

•Mini-driver (DLL) provided for use with Windows based software including LabVIEW and MatLab.

•Programming examples and sample code available for VB, VB.NET, Visual C, Python and others.

•Meets IEC61000-4-2 ESD protection for USB port.

•Available as standard DESKTOP mount, or optional FLANGE, DIN RAIL, or VELCRO mount.