Overview

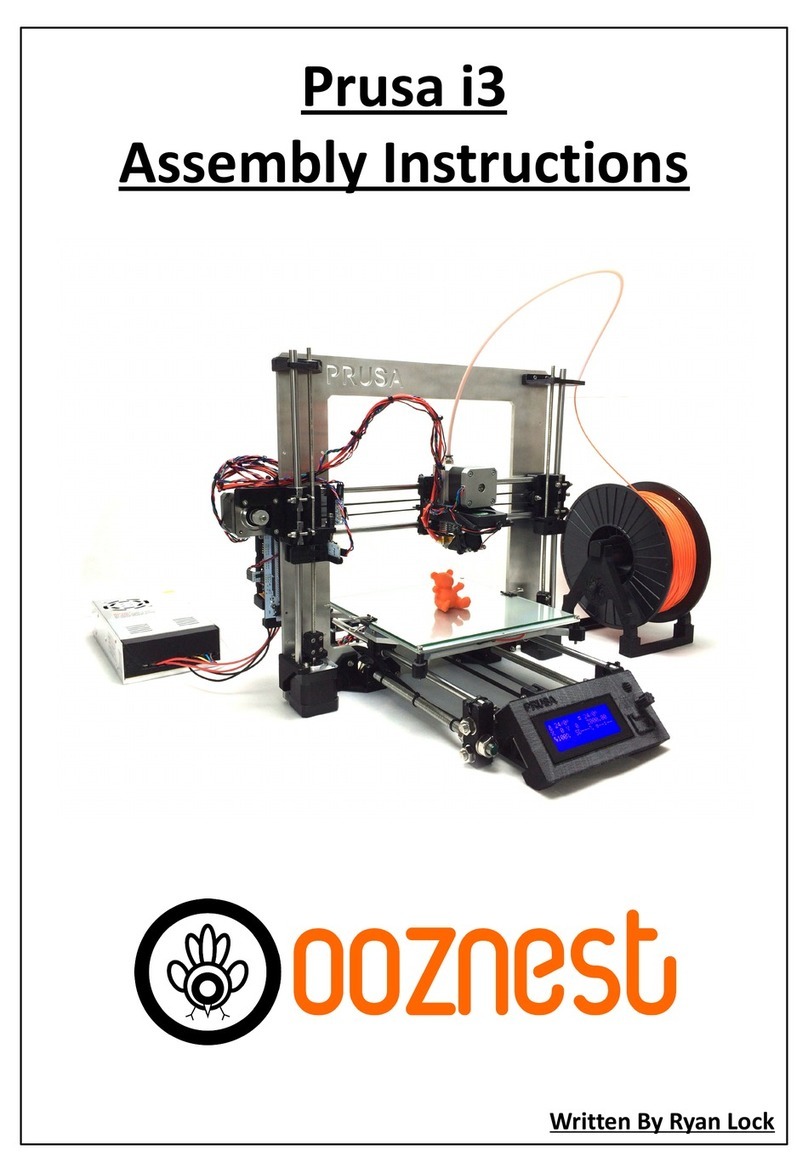

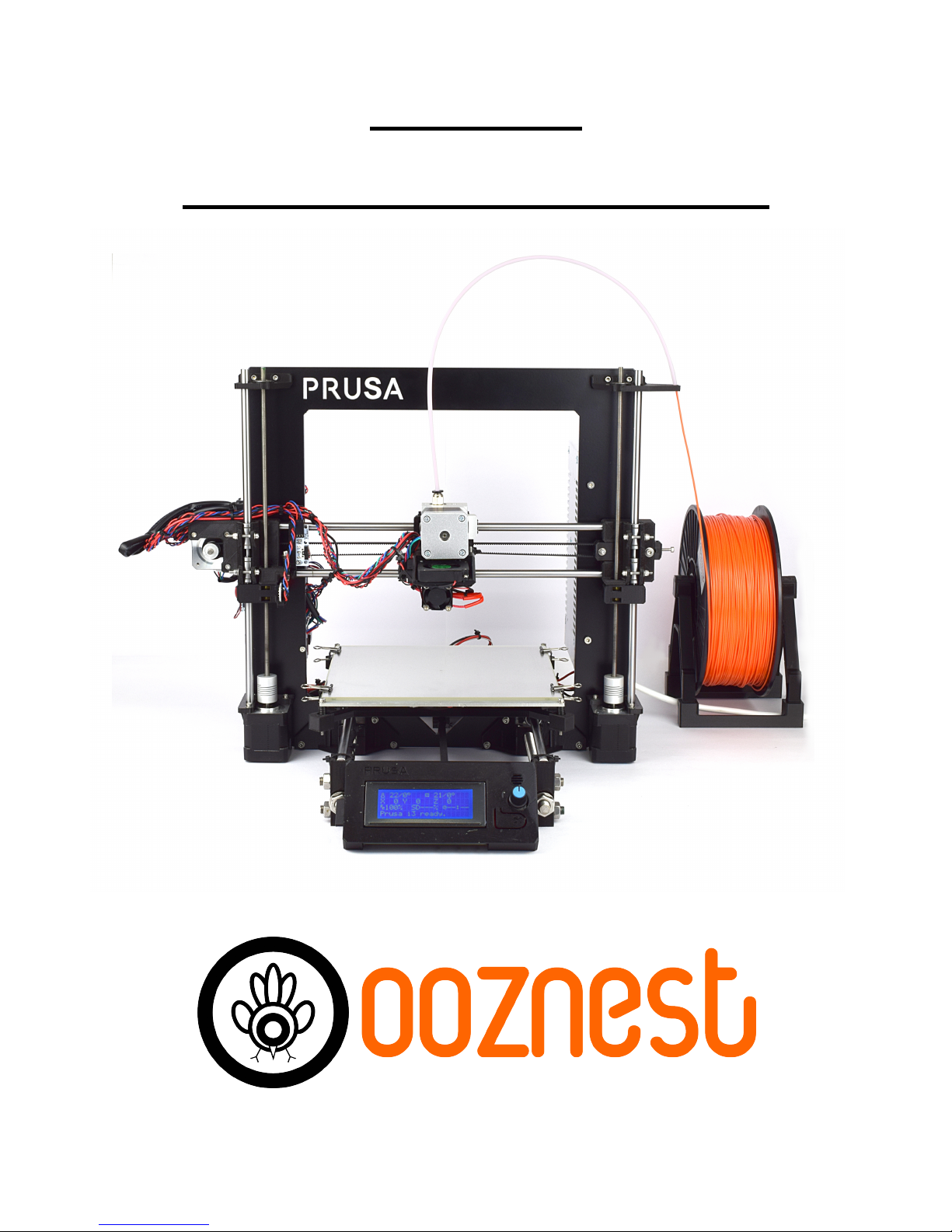

The Prusa i3 is the third iteration in the series of printers designed Josef Prusa. Our kit uses his open-

source design and adds many beneficial upgrades. Our kit includes all the parts required to build a Prusa i3,

plus many extras that ill help you get printing as quickly as possible.

What we have done for you

In our kit, all plastic parts have been pre-prepared and checked for fitting. For plastic parts that require

nuts to be inset, this has been completed. Ho ever, please check the plastic parts box for any that may

have fallen out during shipping. Instruction steps marked ith an '*' means some parts of this step have

already been completed by us.

All ires that need terminal connectors have been pre-crimped and terminals attached. We have not cut

ires to a certain length so you can do the cable management the ay you prefer. Z-Axis motor ires have

been inserted through the holes in the frame.

The MK2B Aluminium heated bed has 1-metre po er ires pre-soldered, and the thermistor is pre-

attached.

The Hexagon Hotend has been assembled ith cartridge heater and thermistor attached. It has been pre-

heated and tightened at 285°C. The Hexagon Hotend has been pre-attached to the Bulldog Lite Extruder.

Arduino Mega2560, RAMPS 1.4 & Stepper drivers (heat sinks still need to be attached) are pre-assembled

and flashed ith pre-configured firm are. The output current on the stepper drivers has also been set.

Notes on assembly

Using Appendix A, check that all parts have been supplied and no parts have been damaged during

shipping. If there are any problems, contact us, and e ill rectify the issue as quickly as possible.

It is recommended to read through the instructions thoroughly before starting assembly.

Ensure you have a clear, firm, and level table to assemble the printer on and you are using tools safely. Also

take extreme caution hen iring electronics.

Most ashers have a flat side and a rounded side. It is recommended to put the flat side against the plastic

part. Take care to not overtighten the nuts & bolts that are in contact ith plastics parts because they may

crack.

If you have any problems contact us (details on our ebsite), and e ill help to resolve the problem.

Most importantly, take your time and have fun!

Tools Re uired

●Allen keys (supplied ith kit)

●5.5/7.0mm Spanners (M3/M4 nuts)

●2 x 13/17mm spanners or 2 x adjustable spanners (M8/M10 nuts)

●Pliers (Preferably Long Nose)

●Mallet or hammer

●Large & small philips scre driver

●Ceramic scre driver (supplied ith kit)

●T eezers

●Scissors

●Ruler

2 of 62