Deezmaker Bukito User manual

1/29/14&&Page&1&of&23&&

&

Steps&for&assembly&of&a&Bukito.&

Beta&version&3.0,&February&7,&2014&

!"#$%&'(&)'*+%*+,&

&

Table&of&contents&.....................................................................................................................&1&

Definitions&and&conventions.&..............................................................................................&2&

Tools&you&will&need,¬&included&in&kit&..........................................................................&3&

Other&items&included&in&kit&..................................................................................................&3&

General&observations&.............................................................................................................&3&

Power&switch&assembly.&........................................................................................................&4&

Z&motor&mount.&........................................................................................................................&6&

Z&axis&kit.&....................................................................................................................................&7&

Y&axis&kit.&....................................................................................................................................&8&

Z&motor&.....................................................................................................................................&10&

Extruder&filament&drive&mechanism&..............................................................................&10&

X&axis&assembly&......................................................................................................................&13&

Z&Screw&......................................................................................................................................&16&

Y&platform&................................................................................................................................&17&

Attaching&the&platform&........................................................................................................&19&

Handle&.......................................................................................................................................&21&

Filament&tube&.........................................................................................................................&21&

Applying&blue&tape&................................................................................................................&22&

AddRon&&PLA&cooling&fan&......................................................................................................&23&

Plug&in&the&power&supply.&...................................................................................................&23&

&

&

&&

1/29/14&&Page&2&of&23&&

-%(.*.+.'*,&"*/&)'*0%*+.'*,1&

The&parts&are&collected&into&kits&(individual&plastic&bags.)&Where&possible,&we&will&

walk&you&through&all&the&parts&in&a&kit&and&highlight&the&kit&name&&in&yellow.&In&some&

cases&we&will&have&you&use&a&few&parts&from&different&kitsF&we&will&point&out&where&

you&open&a&kit&for&the&first&time.&&

The&X&axis&runs&along&the&horizontal&bar&that&runs&from&right&to&left&in&this&photo.&

The&extruder&is&carried&on&the&X&carriage..&

The&Y&axis&is&the&bar&that&runs&underneath&the&platform&(Y&direction&movement&is&

done&by&the&platform).&Or,&toward&and&away&from&you&in&this&photo.&&

The&Z&axis&is&the&vertical&axis.&&

The&“front”&of&the&Bukito&is&the&&defined&here&as&the&end&of&of&the&Y&axis&closest&from&

the&Azteeg&board&mount.&(Or&to&put&it&another&way,&the&Azteeg&and&other&electronics&

will&be&in&the&front,&and&the&power&switch&will&be&on&the&left&(See&image&below&of&

assembled&Bukitos–&refer&back&to&this&if&you&get&lost.)&&When&we&say&“left”&&or&right&

we&mean&from&the&point&of&view&of&an&observer&looking&at&the&machine&from&the&

front.&&

&

&

&&&&&&Z&

&

&

&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&X&&&&

&

&

&&&&&&&&&&&&&&&&&Y&

&

&

&

&

&

1/29/14&&Page&3&of&23&&

!''$,&2'3&4.$$&*%%/5&*'+&.*)$3/%/&.*&6.+&

PhillipsFhead&screwdriver&(00&size)&

A&roll&of&3M&blue&painter’s&tape&(“ScotchBlue”)&for&the&platform,&if&you&will&be&

printing&in&PLA.&&

Metric&allen&wrenches&(1.5,&2&and&3&mm)&

7+8%9&.+%:,&.*)$3/%/&.*&6.+&

&&

We&include&a&piece&of&nylon&filament&for&cleanout&if&the&nozzle&clogs&(see&

www.bukobot.com).&&

We&include&a&test&piece&of&PLA&filament.&&

;%*%9"$&'#,%90"+.'*,&

&

If&you&are&an&experienced&assembler&of&electronics,&you&may&find&the&following&

obvious.&&If¬,&some¬es&about&assembly&in&general:&&

•&&Many&pieces&have&rectangular&and&slide&nuts.&These&nuts&are&designed&to&

lock&in&the&slots&in&the&sides&of&the&aluminum&bars.&You&just&need&to&get&

them&started&and&they&will&selfFalign.&The&slide&nuts&should&be&installed&

with&the&protrusion&toward&the&inside&of&the&slot,&with&the&exception&of&

the&ones&connecting&the&idlers.&&

•&&By&and&large,&it’s&a&bad&idea&to&cinch&down&nuts&on&the&first&pass.&We&will&

discuss&this&as&we&go.&

•& Each&end&stop&gets&a&ribbon&cable&connection.&The&other&end&of&these&

connectors&are&labeled&on&the&board&and&also&cut&to&a&length&that&should&

make&them&tight&connections&when&allocated&correctly.&If&a&ribbon&cable&

has&significant&slack,&it&probably&isn’t&the&right&one!&Look&at&these&

carefully&before&beginning.&&

•& Most&of&the&screws&are&either&M3&(3&mm)&&or&M5&(5&mm)&size.&&

•&& IMPORTANT:&In&some&cases&we&have&shown&parts&where&they&WILL&go&to&

make&it&clearer&how&to&align&them,&but&the&actual&connections&may&be&

made&a&few&sentences&farther&down&in&the&instructions.&Where&this&

happens&we¬e&it.&In&some&cases&the&prototype&parts&we&used&for&

instructions&look&a&little&different&or&have&connectors&on&a&different&side;&

we¬e&that&where&it&happens&too&and&will&have&updated&pictures&soon.&&

1/29/14&&Page&4&of&23&&

&

<'4%9&,4.+)8&",,%:#$21&&

Open&the&Power&switch&

assembly&kit.&&

Gather&up&the&main&

assembly(baseplate,&

control&board&and&

extruder,&with&cables)&

and&the&two&aluminum&

11&inch&extruded&rods.&&

&&&

&

&

&

&

&

&

Attach&the&acrylic&piece&

with&the&power&switch&

to&the&baseplate&

assembly&using&the&M5&

(longer)screw&and&

square&nut&and&then&

the&M3&(shorter)&screw.&&

&

&

&

&

&

&

&

1/29/14&&Page&5&of&23&&

&&

Attach&the&small&acrylic&piece&to&the&

back&of&the&power&connector&board&&

(small&oval&green&circuit&board)&

with&the&two&slide&nuts&and&M3&

screws.&&Align&it&so&that&the&cutouts&

are&over&the&protruding&connections&

on&the&board.&&

Pick&up&the&aluminum&bar&marked&

“z&axis.”(Note:&the&aluminum&bar&is&

shown&here&attached&to&the&base&

plate&to&allow&you&to&anticipate&–&

you&should&NOT&have&this&bar&

attached&yet.)&&

Slide&the&nuts&into&the&wider&side&of&the&aluminum&bar.&Slide&the&piece&to&near&the&

bottom&of&the&bar.&&

Connect&the&red&and&black&wires&into&

the&holes&at&90°rees&to&the&small&

screws.&&Tighten&the&small&Phillips&

screws.&&&Be&sure&there&are&no&stray&

strands&hanging&out&as&this&can&cause&

shorts.&Twisting&the&ends&a&bit&before&

inserting&them&may&help.&&&Red&wire&

goes&into&the&V+slot&and&black&wire&to&

GND.&&&

Note&that&in&this&picture&the&acrylic&

cover&is&behind&the&green&board,&and&

the&nuts&are&on&the&far&side&slotted&into&

the&aluminum&bar.&It&can&be&a&little&

tricky&to&handle&all&the&pieces&(here,&

the&assembled&main&electronics&board&which&you&will&have&on&your&system&at&

delivery&is¬&shown;&&you&should¬&have&attached&the&z&axis&to&the&baseplate.)&At&

the&end&of&this&process&the&Z&axis&should&have&the&power&connector&board&loosely&

attached.&&

Take&the&power&connector&board&and&loosen&the&small&screws&in&the&blue&connector&

box&on&the&green&power&board&with&a&Phillips&head&screwdriver&just&enough&so&that&

you&can&insert&the&stripped&wire&ends&into&the&holes&at&90°rees&to&the&small&

screws.&

1/29/14&&Page&6&of&23&&

Put&the&rectangular&

nut&on&the&side&of&the&

baseplate&into&the&

narrow&side&of&the&

aluminum&bar.&&Turn&

the&nut&sideways&so&

the&nut&can&get&into&

the&slot&and&insert&

M5&screw&into&the&

side&of&the&baseplate&

(thus&attaching&the&

side&of&the&Z&axis).&&&

Carefully&slide&down&

the&Z&axis&over&these&

nuts&and&attach&it&to&

the&baseplate.&

Tighten&down&all&

sliding&nuts&and&M5&screws.&&Attach&the&bottom&of&the&Z&axis&with&the&remaining&M5&

screws.&&

Take&the&other&red&wire&(not¤tly&attached&to&anything)&and&insert&it&into&the&&&

+&terminal&of&the&main&electronics&board&(you&will&need&to&take&off&the&acrylic&cover&

to&do&this,&which&involves&taking&off&three&screws&with&an&allen&wrench.)&&

Tighten&down&the&small&Phillips&screws.&&Take&the&black&wire&from&the&power&plug&

connector&board&and&attach&it&to&the&R&terminal&on&the&main&board.&&

Attach&the&red&wire&from&the&main&electronics&board&into&the&top&of&the&switch.&&

Attach&the&red&wire&from&the&power&plug&board&into&the&bottom&of&the&switch.&&

=&:'+'9&:'3*+1&&

Open&the&Z&motor&mount&kit.&

Put&in&screws&from&each&side&into&the&white&block&such&

that&the&screw&tips&are&closest&to&the&black&mark.&&Put&

the&big&black&(M5)&screws&in&and&out&a&few×&to&

loosen&up&the&holes&a&bit.&&Put&the&thinner&(M3)&screws&

in&so&they&are&just&flush&with&the&surface&of&the&white&

block.&This&picture&was&taken&before&we&added&the&

black&marksF&the&black&mark&would&be&on&the&top&and&

front&of&this&piece.&&

& &

1/29/14&&Page&7&of&23&&

Put&the&piece&on&top&of&one&motor&such&that&

if&the&motor&connector&is&toward&you,&the&

white&piece&is&on&the&left&with&the&black&line&

facing&out&(the&M5&black&screw&heads&should&

face&toward&the&motor¢er).&The&black&

line&will&then&disappear&when&it&is&attached&

to&the&aluminum&bar.&&The&nuts&should&be&

loose.&&Set&aside&for&now.&&

&

&

=&">.,&6.+1&&

Open&the&Z&axis&endstop&kit&and&assemble&the&screws&and&acrylic&cover&such&that&the&

acrylic&cover&cutouts&are&over&the&protruding&parts&of&the&circuit&board.&Add&the&

motor&cable&(thinner&cables,¬&a&ribbon&cable.)&&Slide&the&nuts&into&the&Z&(vertical)&

axis&aluminum&bar&such&that&the&white&connector&is&down.&Attach&the&Z&axis&

insulation&displacement&connector&(ribbon&cableF&should&be&appropriate&length&so&

that&it&just&fits)&into&the&blue&socket.&Then&&press&the&part&until&the&bottom&of&the&

acrylic&touches&the&bottom&plate&and&tighten&the&screws.&&&&&&

Note:&these&pictures&show&

the&Z&motor&installed.&Do&

not&install&it&just&yet&–&this&

is&just&to&allow&you&to&

anticipate&where&the&part&

you&just&put&in&will&be&

attached&later.&(It&gets&

hard&to&see&when&the&other&

pieces&that&we&are&about&to&

put&in&are&installed!)&&&

&

&

&

&

&

&

1/29/14&&Page&8&of&23&&

&

?&">.,&6.+1&&

Open&the&Y&axis&kit&&and&attach&the&acrylic&piece&&to&the&board&using&the&two&longest&

(12mm)&M5&screws&and&two&nuts.&&&

Put&the&two&shorter&M5&(10&mm)&screws&through&the&holes&in&the&Bukito&baseplate&

and&put&a&rectangular&nut&loosely&on&each.&&The&12&mm&will&go&through&the&longer&

hole&(through&the&metal&baseplate)&&and&the&10&mm&through&the&upper&hole.&&

Take&the&y&end&stop&and&attach&the&motor&cable(not&a&ribbon&cable.&)Attach&it&on&the&

outside&of&the&base&plate&next&the&acrylic&piece&with&M3&screws.&Use&the&two&closest&

holes&to&the&acrylic&piece.&&&Attach&the&ribbon&cable&and&connector&(trace&back&to&the&

“y”&on&the&main&electronics&board)&to&the&y&end&stop.&&

&

&

&

&

1/29/14&&Page&9&of&23&&

Take&the&other&large&aluminum&bar&and&place&it&over&the&nuts;&slide&until&it&is&just&

level&with&the&big&circular&hole&on&the&acrylic&piece&.&Tighten&down.&&Attach&the&white&

cable&from&the&y&motor&power&board&to&the&y&motor.&&

&(Note:&in&this&image&the&z&motor&and&screw&&is&already&there&to&show&

placement&but&you&should¬&place&the&motor&yet).&&&&&

&

The&y&axis&acrylic&should&

be¶llel&to&the&y&axis&

aluminum&bar.&Bottom&of&

the&acrylic&should&be&

flush&with&the&aluminum&

bar.&&

Take&a&motor&and&attach&

the&white&connector&to&

the&board&you&just&

attached,&and&attach&the&

motor&with&the&three&

screws&provided.&&We&are&

talking&about&the&motor&

with&the&shaft&pointed&

toward&us&in&this&picture.&&&&

1/29/14&&Page&10&of&23&&

=&:'+'9&

Now&attach&the&z&motor&&by&sliding&it&down&the&z&axis.&Attach&the&connector&from&the&

z&motor&board&and&tighten&the&motor&down.&&

&

&

&

&

&

&

&

&

&

&

&

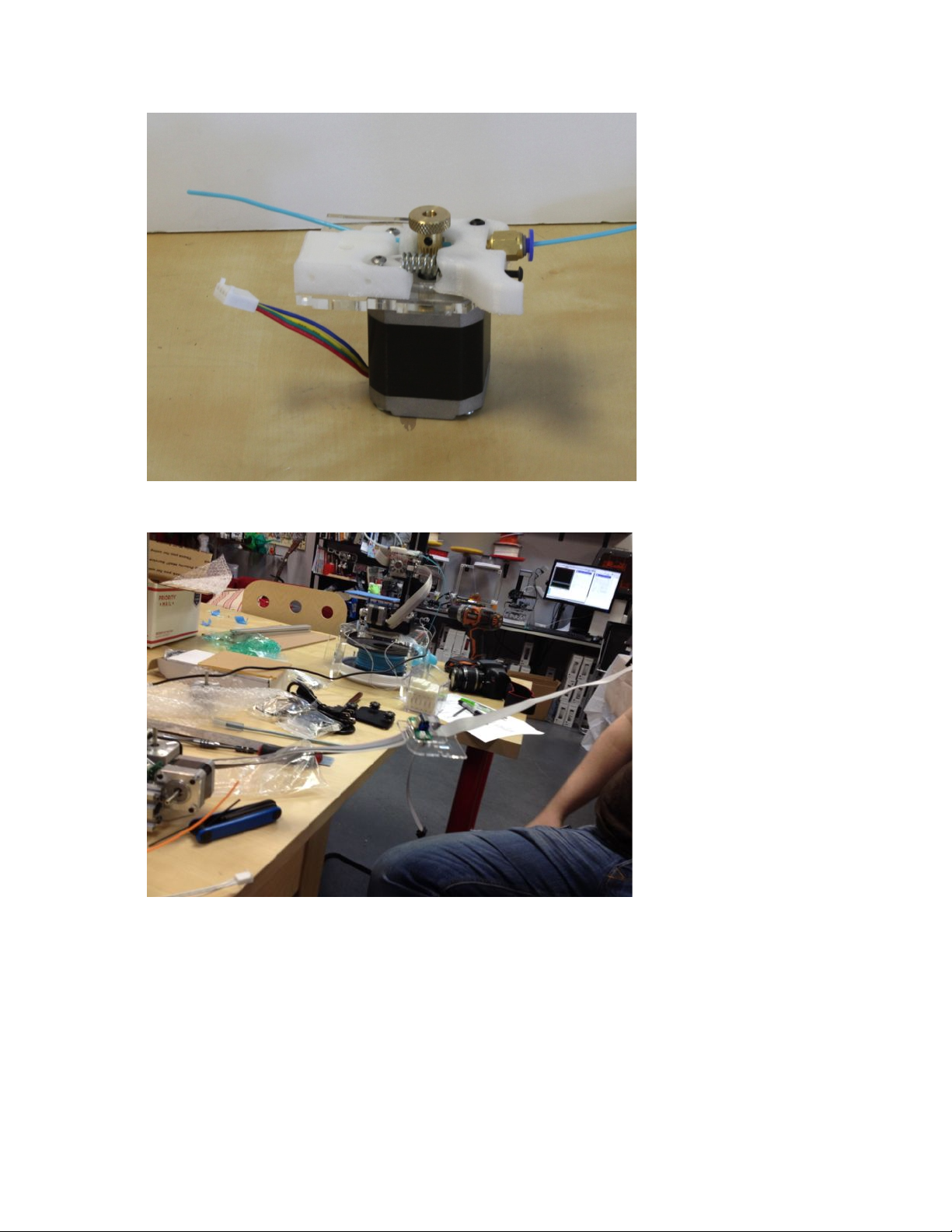

@>+93/%9&(.$":%*+&/9.0%&:%)8"*.,:&&

Open&&the&extruder&drive&

mechanism&kit.&&Be&sure¬&to&

lose&the&small&piece&–the&

spring&(a&few&steps&down)&

hooks&over&the&narrow&part&of&

this&small&acrylic&piece.&The&12&

mm&M3&screws&go&through&the&

acrylic&piece.&&

&

&

&

&

&

&

1/29/14&&Page&11&of&23&&

Take&one&motor&and&lay&clear&acrylic&piece&so&that&shaft&pokes&through&on&top&with&

wider&end&toward&the&connector.&&Set&the&motor&and&acrylic&aside&for&now.&(This&step&

not&shown&in&a&picture.)&&

&

Then,&take&the&plastic&piece&

shown&here.&

&

Drop&M5&screw&head&in,&tip&

out,&into&the&hole&in&the&part&

with&the&blue&flange.&Next&

drop&in&the&spring&over&that&

screw&tip.&(Hole&is&in&front&of&

you&–&screw&point&is&facing&

toward&you.&Spring&will&be&

over&that&tip.)&

&

Assemble&as&shown&below.&&HOWEVER&in¤tlyFshipping&&motors,&the&motor&

connector&is&on&the&other&side.&&

&

.&&&

&

&

&

&

&

&

&

&

&

&

&

1/29/14&&Page&12&of&23&&

Put&&filament&in&to&

check&drive&gear&

alignment.&&&Motor&

connector&should&

be&on&opposite&

side&from&blue&

flange&in¤tly&

shipping&motorsR&

this&is&an&older&

motor&New&images&

coming&soon.&&

&

&

&

&

&

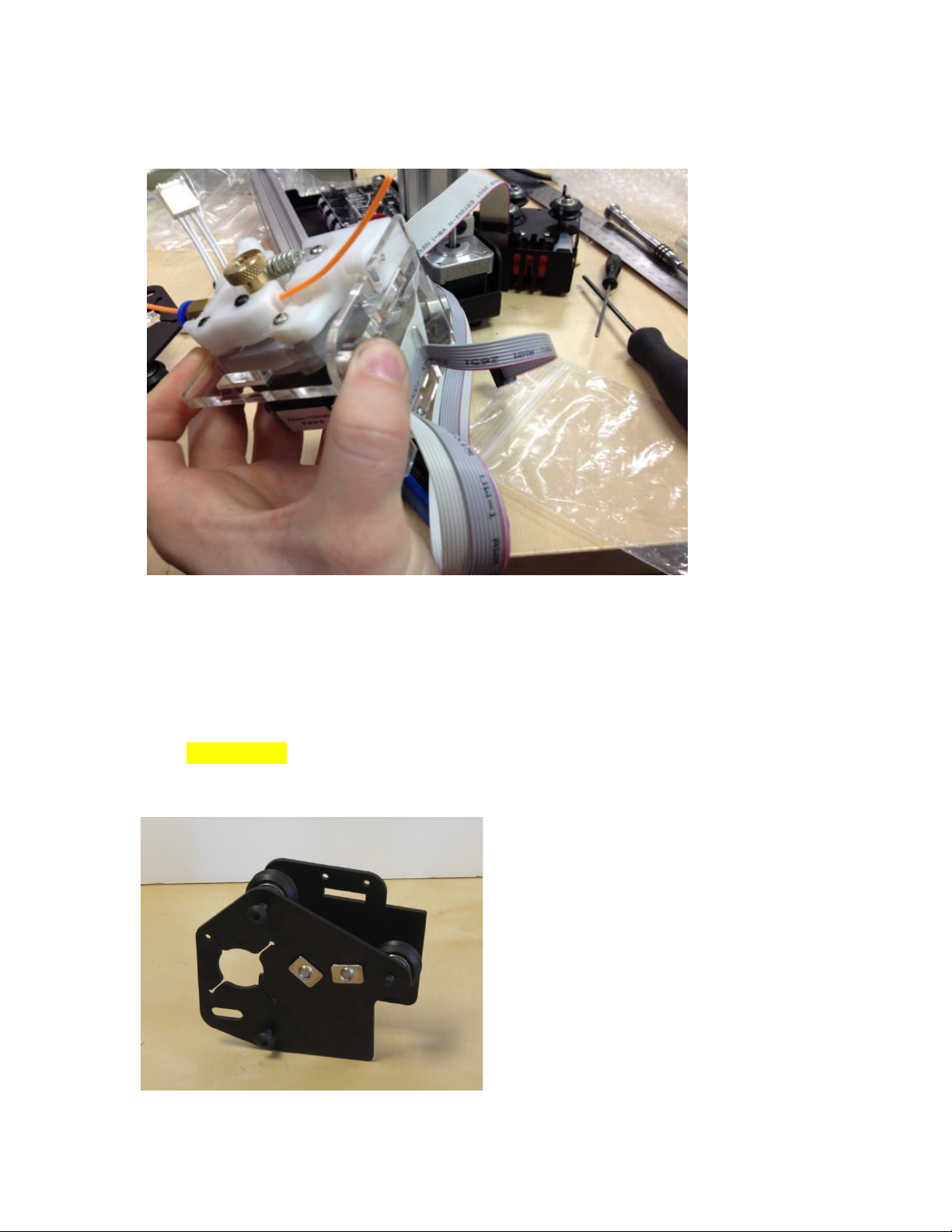

Now&straighten&out&

wires&and&arrange&

things&so&that&you&

can&get&at&the&wire&

clamp&panel&(acrylic&

piece&&and&board&on&a&

ribbon&cable,&already&

attached&to&the&main&

electronics&board.)&&

&

&

&

&

&

&

&

&

&

1/29/14&&Page&13&of&23&&

Attach&that&panel&to&the&extruder&&drive&mechanism.&It&will&become&the&left&side&of&a&

3Fsided&partial&acrylic&box&around&the&extruder&drive&motor&assembly.&

Plug&motor&

into&circuit&

board&on&

assembly.&&&

Add&the&fan&–&

attach&acrylic&

piece&and&

press&fit&into&

place&(far&end&

first).&&

&

&

&

&

&

The&fan&will&be&the&back&of&the&threeFsided&acrylic&box&around&the&extruder&drive&

mechanism&left,&front,&and&top&sides.&&The&filament&drive&gear&will&be&on&top.&Use&

tabs/slots&and&M3&screws&to&assemble.&&

A&">.,&",,%:#$2&

Open&the&x&axis&kit&and&set&aside&the&XFaxis&carriage&(prebuilt&for&you&as&shown.)&&

&

&

1/29/14&&Page&14&of&23&&

Mount&the&x&motor&onto&it&using&the&standoffs&in&the&kit;&be&sure&the&connector&faces&

down&(away&from&the&drive&assembly).&&

&

Align&syncromesh&pulley&&(white&

plastic&part)&with&slot&of&the&

extruded&aluminum&rod.&&Once&it&is&

aligned,&rotate&the&pulley&so&that&the&

small&screw&on&the&side&(dark&spot&

on&side&in&image)&is&on&the&flat&part&

of&the&motor&shaft&so&that&it&can&be&

tightened&down.&&

&

&

&

&

Take&shorter&of&the&two&pieces&of&

synchromesh&cable&and&be&sure&there&is&a&

washer&on&either&end.&&&Put&the&cable&in&the&

slot&of&the&top&of&the&x&carriage&aluminum&

bar.&&&&&

Take&the&extruder&carriage&and&slide&it&

onto&the&x&axis&by&sliding&it&onto&the&back&

slot&on&the&x&axis&aluminum&bar.&&Be&careful&

to&place&the&wheels&over&the&synchromesh&

before&sliding&fully&onto&the&beam.&&&Then&

hook&the&synchromesh&into&the&tabs&on&the&

bottom&of&the&X&carriage.&&

Next&take&the&synchromesh&idler&(piece&of&

acrylic&with&a&roller)&and&attach&it&to&the&

back&of&the&end&of&the&x&axis.&Adjust&the&

tension&of&the&synchromesh&by&pulling&the&

idler&away&from&the&end&of&the&x&axis.&

Adjust&the&synchromesh&to&be&tight&enough&

so&that&it&takes&some&force&to&tighten&down&

the&idler&into&position.&Be&sure&the&synchromesh&isn’t&binding&or&dragging&anywhere.&&

It&should&be&tight&enough&that&it&does¬&lift&off&the&idler&or&pulley&on&the&other&end&–&

about&the&same&tension&as&a&steelFstring&guitar&string.&&

&

1/29/14&&Page&15&of&23&&

&

Take&the&x&end&stop&kit&and&

put&the&acrylic&cover&over&

the&circuit&board,&aligning&

so&that&the&protruding&

parts&of&the&board&are&in&

the&cutouts.&&&&&Attach&the&

part&with&the&Bukito&logo&

to&the&other&side&(facing&

away&from&you&in&this&

photo.)&&

&&

&

&

& &

&

&

1/29/14&&Page&16&of&23&&

Plug&in&end&stop&ribbon&

cable&(should&trace&to&“x”&

on&main&board);&the&motor&

cable&goes&through&oblong&

hole&black&metal&plate&

(near¢er&of&image&

below)&Plug&in&motor&&

cable&(ribbon&cable)&into&

blue&connector.&&

&

&

&

&

Attach&extruder&drive&gear&assembly&to&x&axis&assembly&(process¬&shownF&look&at&

picture&of&completed&Bukito&on&last&page&of&instructions&for&overall&alignment).&&

=&B)9%4&&&

&

Put&z&screw&into&white&plastic&of&

extruder&screw&assembly.&&(You&are&

looking&up&from&what&will&be&the&

bottom&of&the&screw.)&Screw&into&

plastic&piece&until&it&starts&to&come&out&

other&side.&&

&

Slide&x&carriage&onto&front&of&z&axis&

and&extruder&assembly&onto&back&and&

be&sure&that&all&wheels&and&z&screw&

align.&&You&might&want&a&friend&to&help&

you&hold&pieces&as&you&do&this&part.&&

&

&

&

&

&

1/29/14&&Page&17&of&23&&

&

&

Squeeze&plastic&tube&onto&z&axis&and&

push&down.&Squeeze&while&pushing&

down&so&that&tube&will&widen&a&bit&

while&being&forced&along.&&

Put&a&cable&tie&on&the&plastic&tube&just&

above&the&z&motor&mount&white&piece&

and&another&near&the&top&of&the&screw&

cover.&&Make&these&as&tight&as&possible&

to&prevent&shafts&from&turning&in&tube.&&

&

&

&

&

?&C$"+('9:&

Slide&the&y&platform&carriage&onto&the&y&carriage&aluminum&bar.&&

Run&the&remaining&piece&of&synchromesh&through&the&channel&in&the&MIDDLE&of&the&

aluminum&rail.&Be&sure&that&you&have&a&washer&on&either&end.&&

&

&

&

&

&

&

&

1/29/14&&Page&18&of&23&&

&

&

&

Hook&the&synchromesh&on&the&back&

side&of&the&Y&carriage&then&slide&onto&

rail.&Hook&front&end&before&sliding&all&

the&way.&&

&

&

&

&

&

&

&

&

&

Attach&ends&of&syncromesh&to&bottom&

of&platform&and&put&on&and&adjust&

idler&as&you&did&on&the&x&carriage.&

Tighten&similarly.&&

&

&

&

&

&

&&

&

1/29/14&&Page&19&of&23&&

&

D++")8.*E&+8%&C$"+('9:&

&

Open&the&&platform&attachment&kit&&

Take&the&platform&(shown&here&as&clear&acrylic,&but&production&kits&will&be&made&of&

garoliteFLE,&a&tan&linenFphenolic&composite.)&&Put&the&three&long&screws&and&springs&

on&as&shown.&&

& &&

Take&the&flowerFshaped&adjuster&wheels&and&small&nuts&and&drop&a&washer&into&the&

indentation&in&each&gear.&&Press&into&place.&

&

1/29/14&&Page&20&of&23&&

Take&the&platform&and&&connect&it&to&the&carriage&as&shown.&&Hold&the&platform&down&

with&one&hand&and&tighten&the&screws&(using&the&“flowers”)&as&much&as&you&can.&&You&

will&back&it&off&later&to&adjust&it.&&&

&

&

&

&

&

Other manuals for Bukito

4

Table of contents

Other Deezmaker 3D Printer manuals