INSTRUCTIONS

PARTS LIST

Code Quantity Size (mm) Description Teile-Nr.

PLywood 1 300x210x5 Housing 1

Wooden strip 2 200x40x15 Base plate 2

Modelling plywood 1 300x60x1,5 Top (Version 1) 3

Wooden wheel 2 ø 30 knob 4

Jute material 1 200x145 Loudspeaker cover 5

Loudspeaker 1 ø57 Loudspeaker cover 6

Plastic tube 1 ø4/3 Insulation 7

IC holder 8leg 1 8

Cable 1 2000 Wire aerial 9

IC TDA 7021T 1 Receiver 10

Circuit board for FM-Radio 1 11

IC TDA 7052A 1 NF-Amplier 12

Potentiometer 1MOhm 1 6 13

Capacitor 820 pF 821 1 C4 14

Capacitor 3,3 nF 3n3 2 C6/7 15

Capacitor 1,0 μF 105 1 C10 16

Capacitor 0,47 μF 474 1 C9 17

Capicitor 4,7 nF 4n7/472 1 C5 18

Capacitor 0,1 μF 104 3 C2 19

Capcitor 0,01 μF 103 1 C1 20

Capacitor 33pF 33 1 C3 21

Capacitor 220 μF 1 Capacitor, C8 22

Micro switch 1 19x6 Switch 23

Flat connector 2 6,3 Battery connection 24

Cable red 1 500 Cable 25

Silver wire 1 500x0,6 Coil 26

Zylinderkopfschraube 1 30x3 Sendereinstellung 27

Nuts 1 M3 Mutter 28

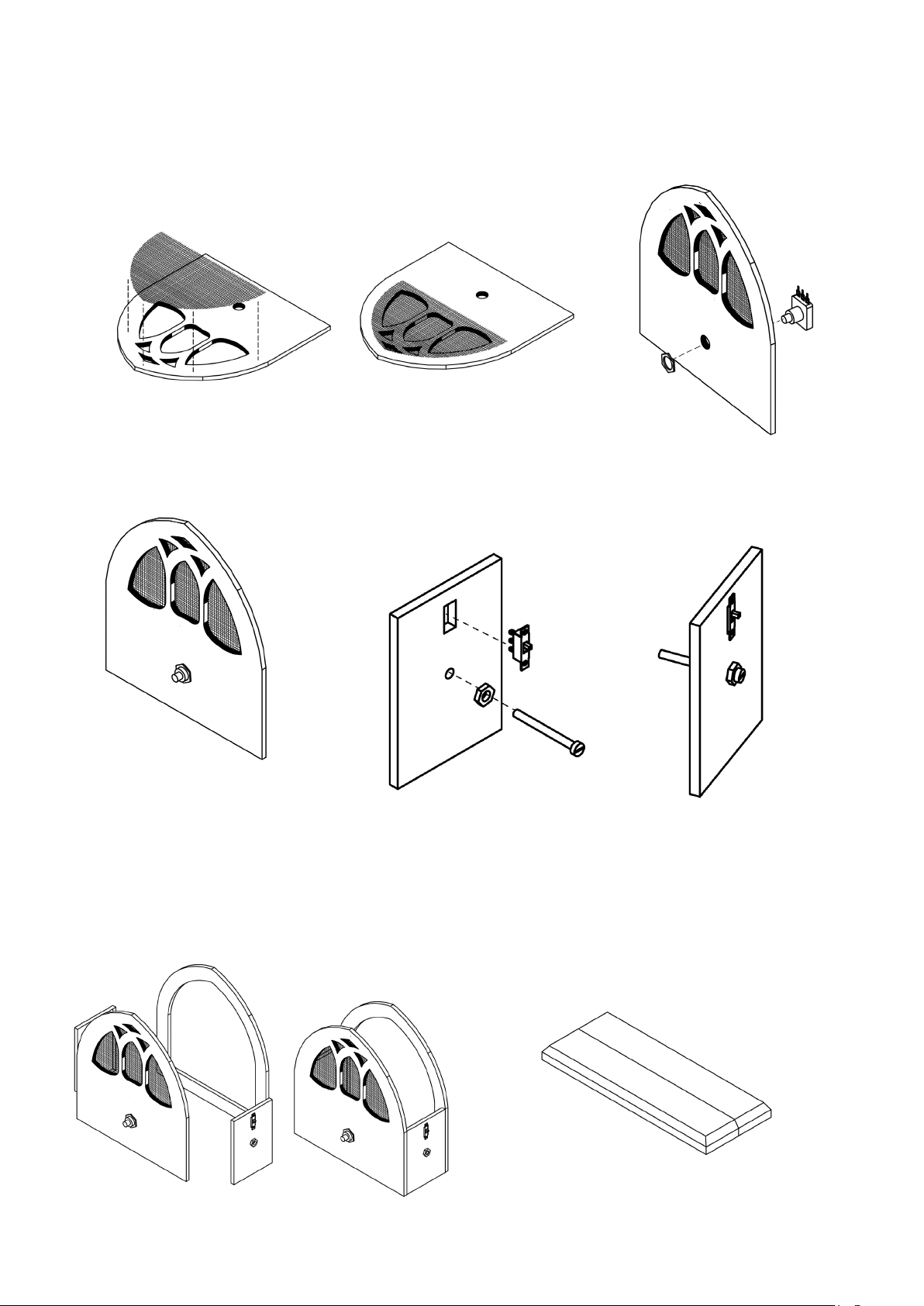

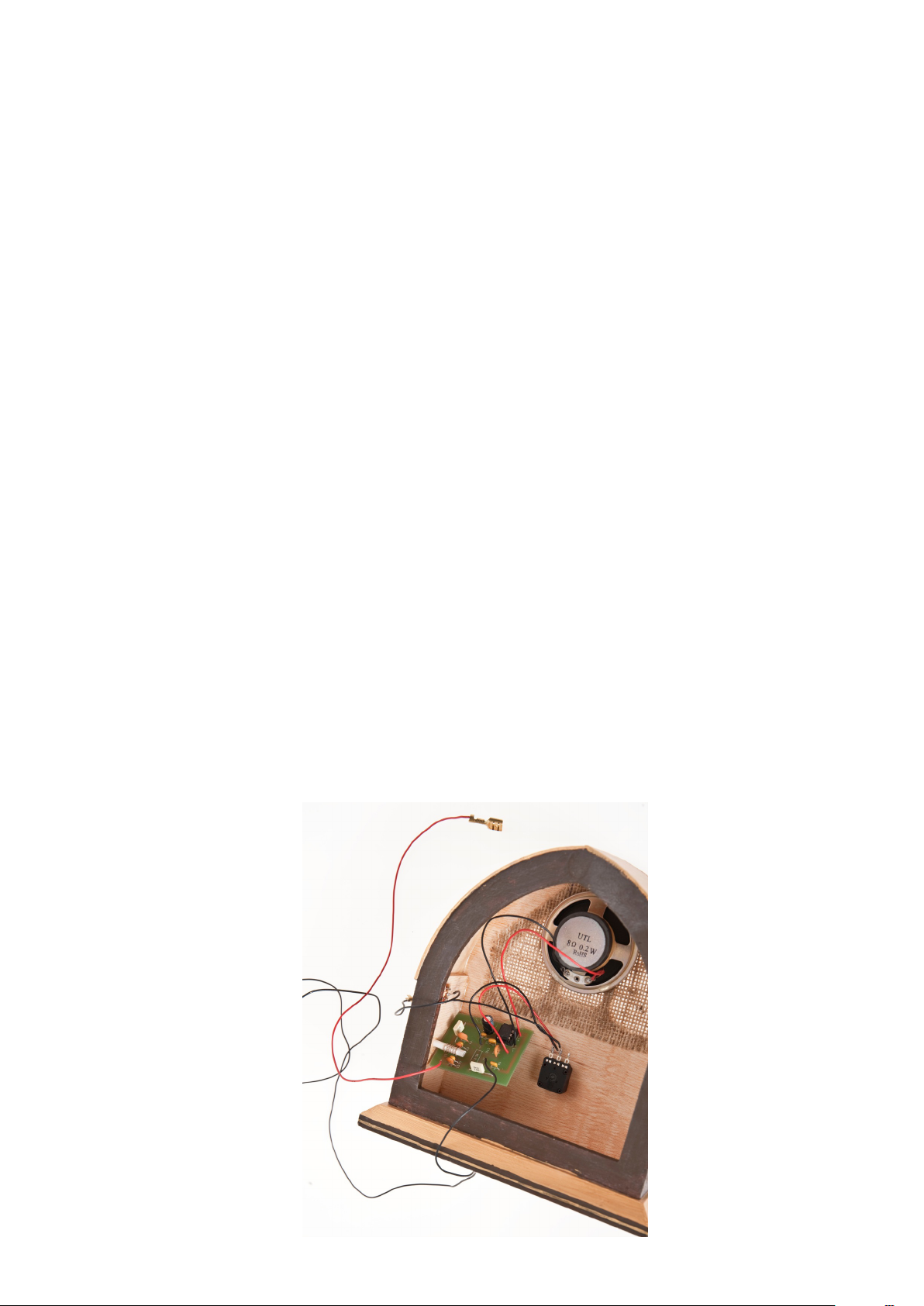

General :

The casing of FM radio is shown in two versions. There are plans for both versions. In the instructions only one variati-

on is described the other version is similar . Both variations are are shown with exploded drawings. (Page 7)

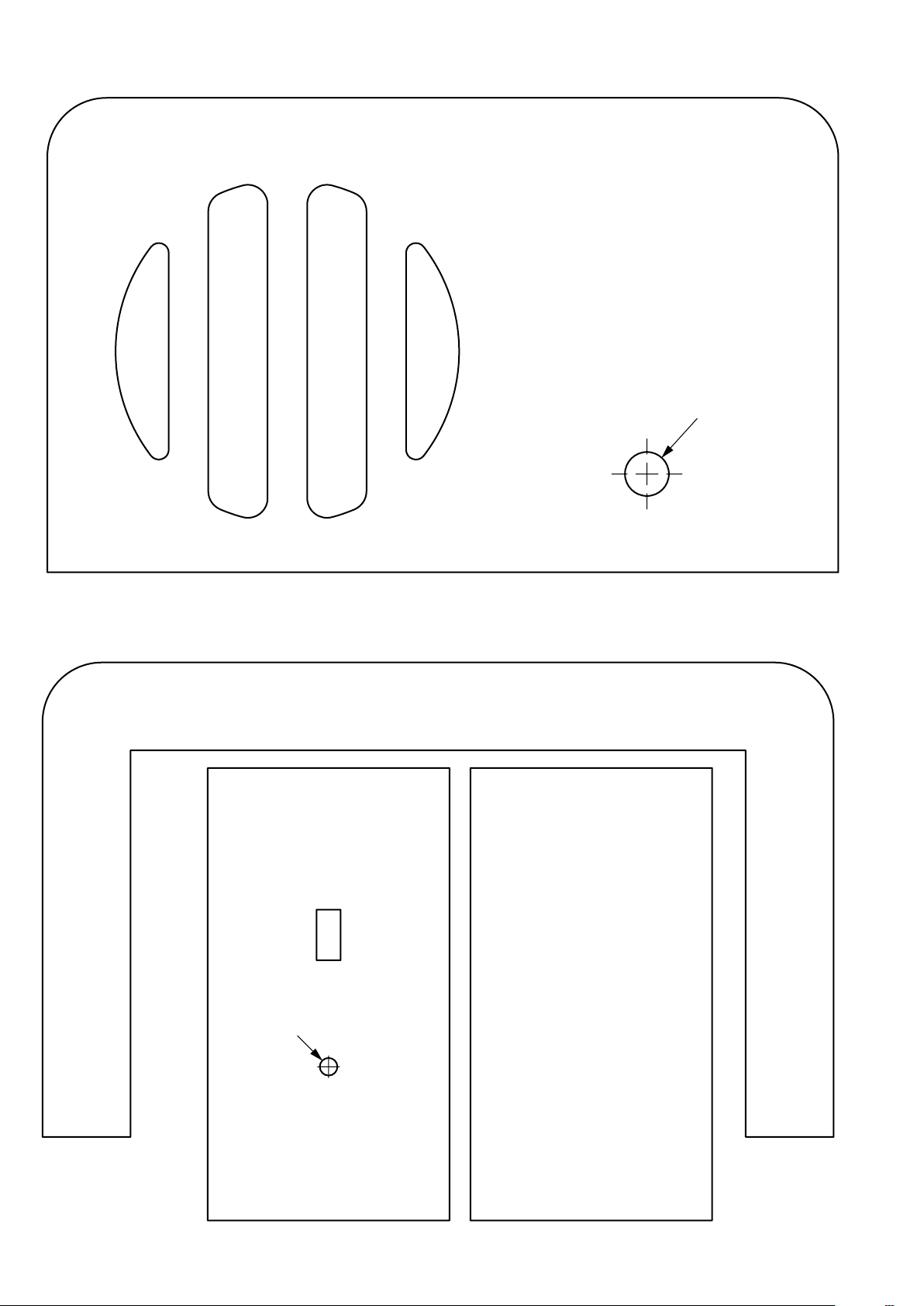

1. Trace or copy the plans for the housing on to

the plywood sheet (1) according to the plan

(see dia 1 and page 6). Saw out the parts with a

fretsaw and sand the edges.

Also saw out any internal shapes and drill the

holes as shown.

Dia.1