THE CLIMATE FACTORY/MANUALS/OPTICLIMATE (INVERTER)

www.theclimatefactory.com info@theclimatefactory.com

© The Climate Factory

WATER-SIDED CONNECTIONS

Supply and drain connections of the cooling water

The unit has a water inlet and outlet. The inlet should be installed at a draw-off point with a solenoid valve

installed between the draw-off point and the inlet (always check the flow direction arrow on the valve!). The

solenoid valve should be installed as close as possible to the draw-off point, as this is the water seal. When

a leak occurs, the solenoid valve closes automatically.

Make sure that the black magnetic coil of the solenoid valve is directed upwards (preferred) or to the side. If

it is directed downwards, condensate from the valve might enter the coil. Make sure that the solenoid valve

is installed at a fixed point that is always easily accessible to the user.

A filter should be placed in the water inlet. This filter prevents blockage in the unit. Disassembly of the filter

often releases dirt into the unit. As such, it may only be removed after contacting the Technical Service de-

partment.

It is recommended to insulate the water supply line in order to prevent condensation build-up. The upper

water connection is the water outlet. The water outlet can be connected directly to the drain (sewer). Alterna-

tively, the warm water can be used for heating purposes.

Note: Only use solid copper or LDPE pipes and affix these properly to the wall using clamps. Always avoid

putting the LDPE under tension. Make sure that the solenoid valve is affixed properly to the wall or another fixed

point. Never use a garden hose!

When all the LDPE connections are checked for leaks and the unit operates properly, all flare fittings should be

glued. You do this by unscrewing the coupling, applying some glue to the thread and re-tightening the blue flare

nut. If done properly, the flare fittings will never come loose as a result of vibration. If it is necessary to loosen the

flare fittings, then two water pump pliers will do the trick.

Copper pipes of 15 mm or LDPE pipes of 16 mm are sufficient for all units. If several units have to cool at

more than 15 kW, the main pipe should be 20 mm copper or 20 or 25 mm LDPE. If the supply pipe has

high pressure, a copper pipe of 15 mm will cool up to 30 kW.

Water drainage

Condensate drainage

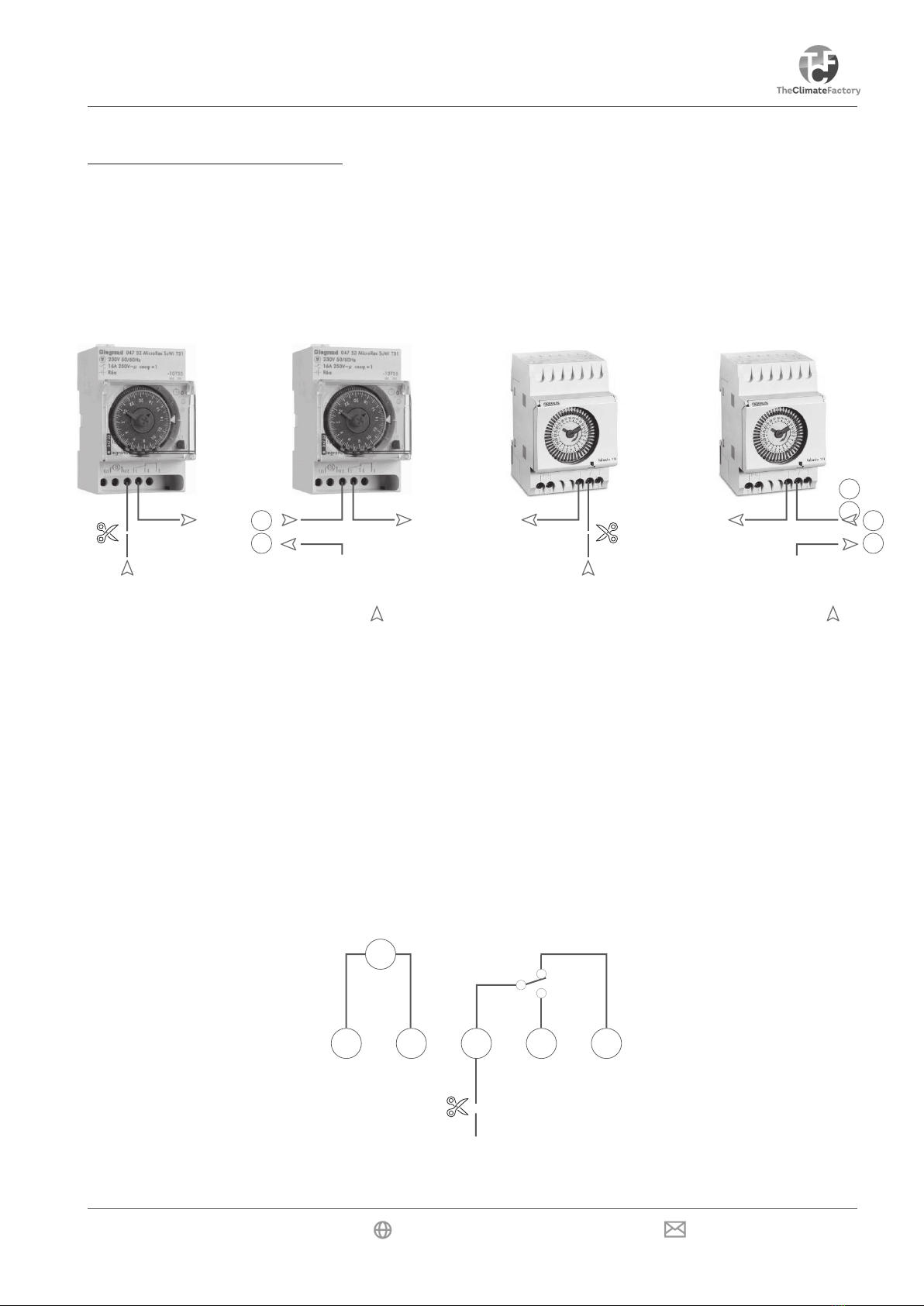

Solenoid valve

16mm PE pipe

Pipe insulation

Solenoid valve in the supply pipe of the water