Page 3

TC20i Temperature Control Instrument

Set-Up Detail

1. Position the TC20i to the right of the Optimec JCF, JCM, SAG, JCFD or is830 instrument.

2. On the left hand side of the TC20i is a cooling fan and it is EXTREMELY IMPORTANT

that it is not obstructed, and that a minimum 10cm space is maintained beteween it and

any other object. Failure to do will restrict the air flow and may result in the failure of the

internal heat exchanger.

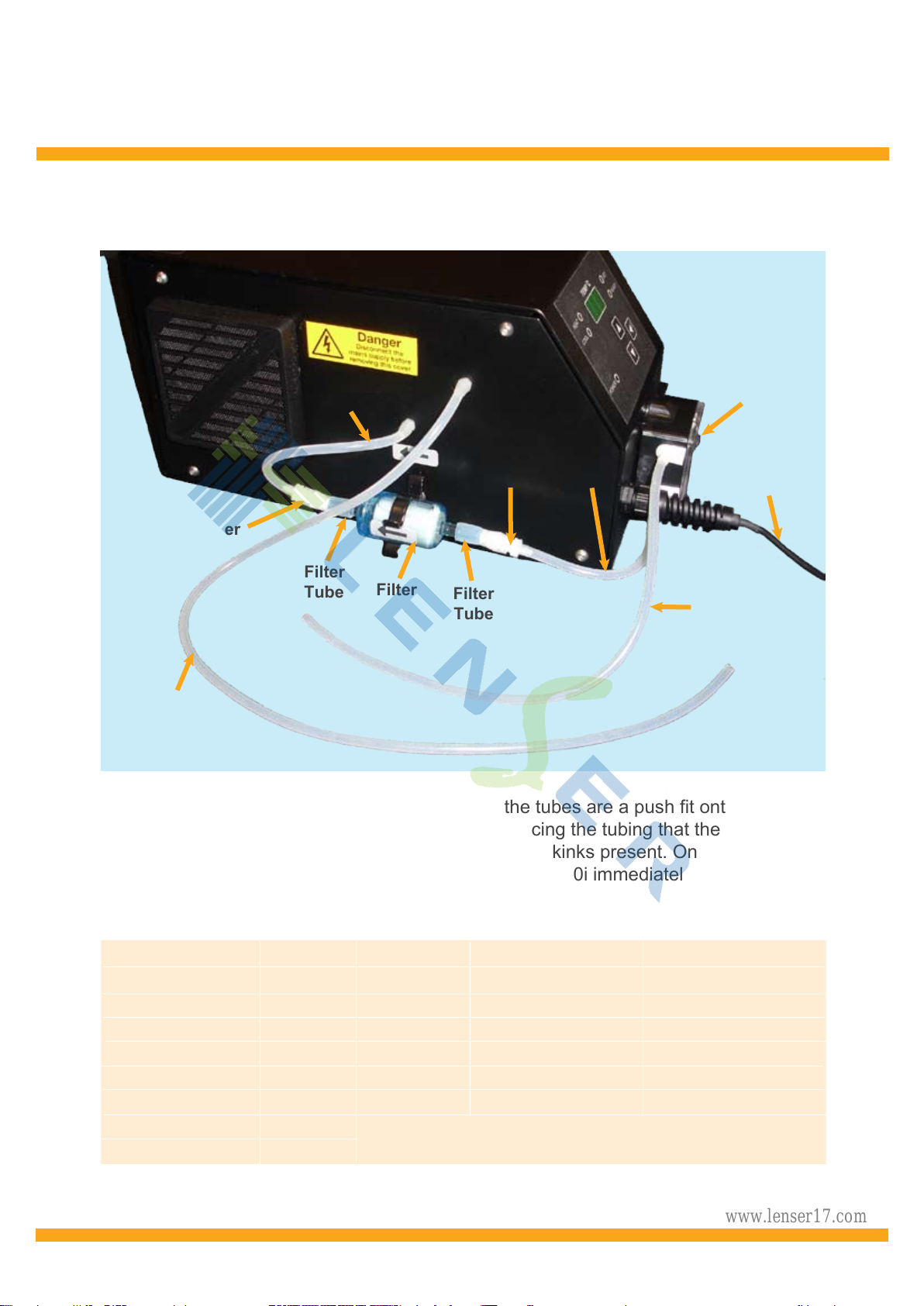

3. Take the clear silicon tube leading from the top of the Peristaltic Pump and connect to the

plastic tube connector on the right hand side of a JCF and JCM analysis cell or to the

upper connector of the manifold block on the right hand side of a SAG instrument.

4. Take the clear silicon tube leading from the side of the TC20i cabinet (longest tube) and

connect to the plastic tube connector on the left hand side of a JCF,JCM, JCFD or is830

analysis cell or to the lower connector of the manifold block on the right hand side of a

SAG instrument.

5. Position the temperature sensor in the analysis cell of the JCF or using the clip bonded

into the analysis cell of a JCM, SAG or is830 instrument.

6. Fill the analysis cell with saline to the correct level (see JCF, JCM, JCFD,SAG or is830

manual).

7. Insert the power lead included with the TC20i into the plug at the rear of the instrument

and switch on the power at the wall. Switch on the TC20i using the switch at the rear

of the instrument.

8. The Green LED (Power) will illuminate to confirm that the instrument is on.

9. When switched on the Peristaltic Pump will rotate and draw saline from the analysis cell

As this happens, the saline level in the cell will fall and bubbles will be seen as the pump

expels air during priming. Top up the saline level in the cell until bubbles no longer appear.

WARNING:

IF SALINE IS SPILT, DISCONNECT THE TC20i FROM THE ELECTRICAL SUPPLY

Avoid spilling saline on the TC20i as it is very corrosive, damaging the paintwork, and should

it come into contact with the electronics, may cause a serious instrument failure and possibly

a risk of electric shock.

WARNING:

DISCONNECT FROM THE POWER SOURCE if the side panels may be removed to check

that no saline is in the cabinet, and left to dry naturally if there is. This is the only circumstance

for the side covers to be removed as there are no user serviceable parts within the cabinet.

总代理:上海朗善光学仪器有限公司 www.lenser17.com