Version 1.0.2 - 2020-07-062 Translation of original instruction

DH 40CT | DH 40CTP

EN

DH40CT_DH40CTP_GBIVZ.fm

Table of contents

1 Safety

1.1 Rating plate.................................................................................................................................................... 6

1.1.1 Machine variants.............................................................................................................................. 6

1.2 Safety instructions (warning notes)................................................................................................................ 7

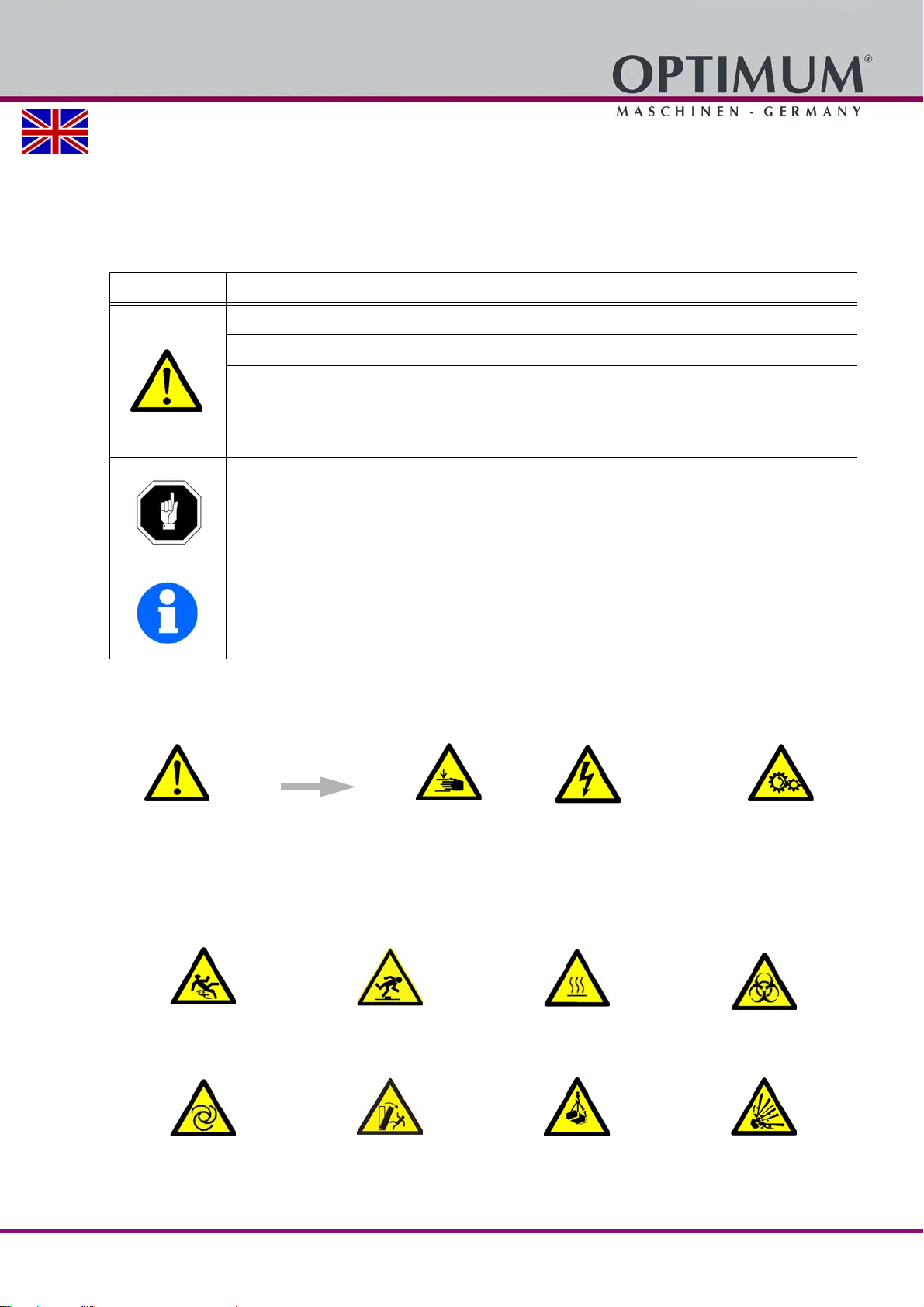

1.2.1 Classification of hazards.................................................................................................................. 7

1.2.2 Other pictograms.............................................................................................................................. 7

1.3 Intended use.................................................................................................................................................. 8

1.4 Reasonably foreseeable misuse.................................................................................................................... 9

1.4.1 Avoiding misuse............................................................................................................................... 9

1.5 Possible dangers posed by the drilling milling machine ................................................................................ 9

1.6 Qualification of personnel............................................................................................................................ 10

1.6.1 Target group................................................................................................................................... 10

1.6.2 Authorized persons........................................................................................................................ 11

1.7 Operator positions ....................................................................................................................................... 12

1.8 Safety measures during operation............................................................................................................... 12

1.9 Safety devices ............................................................................................................................................. 12

1.9.1 Emergency stop button.................................................................................................................. 13

1.9.2 Protective cover ............................................................................................................................. 13

1.9.3 Main switch .................................................................................................................................... 13

1.9.4 Cross table..................................................................................................................................... 13

1.9.5 Drilling milling guard....................................................................................................................... 13

1.9.6 Prohibition, warning and mandatory signs..................................................................................... 13

1.10 Safety check................................................................................................................................................ 14

1.11 Personal protective equipment.................................................................................................................... 14

1.12 Safety during operation................................................................................................................................ 15

1.13 Safety during maintenance.......................................................................................................................... 15

1.13.1 Switching-off and securing the drilling milling machine.................................................................. 15

1.14 Using lifting equipment ................................................................................................................................ 16

1.14.1 Mechanical maintenance ............................................................................................................... 16

1.15 Accident report............................................................................................................................................. 16

1.16 Electronics................................................................................................................................................... 16

1.17 Inspection deadlines.................................................................................................................................... 17

2 Technical data

2.1 Electrical connection.................................................................................................................................... 18

2.2 Drilling capacity / milling capacity................................................................................................................ 18

2.3 Spindle head................................................................................................................................................ 18

2.4 Cross table................................................................................................................................................... 18

2.5 Dimensions.................................................................................................................................................. 18

2.11 Emissions .................................................................................................................................................... 19

2.6 Work area.................................................................................................................................................... 19

2.7 Speeds......................................................................................................................................................... 19

2.8 Spindle quill feed ......................................................................................................................................... 19

2.9 Environmental conditions............................................................................................................................. 19

2.10 Operating material....................................................................................................................................... 19

2.12 Installation plan DH 40CT | DH40CTP ........................................................................................................ 20

3 Delivery, interdepartmental transport, assembly and commissioning

3.1 Notes on transport, installation, commissioning .......................................................................................... 21

3.1.1 General risks during internal transport........................................................................................... 21

3.2 Unpacking the machine............................................................................................................................... 22

3.3 Scope of delivery......................................................................................................................................... 22

3.3.1 Accessories.................................................................................................................................... 22

3.4 Installation and assembly ............................................................................................................................ 22

3.4.1 Requirements regarding the installation site.................................................................................. 22

3.4.2 Load suspension point................................................................................................................... 22

3.4.3 Assembly........................................................................................................................................ 23

3.4.4 Installation...................................................................................................................................... 23