6

V 1.03 - eng

LTDVE2CH-20F | INSTRUCTIONS MANUAL

4. General description

Any machine vision application employs some kind of light controller. Light controllers are widely

used to both optimize illumination intensity and obtain repeatable trigger sequencing between lights

and vision cameras.

This controller is a compact unit that includes power supply conditioning, intensity control, timing

generation and advanced triggering functions.

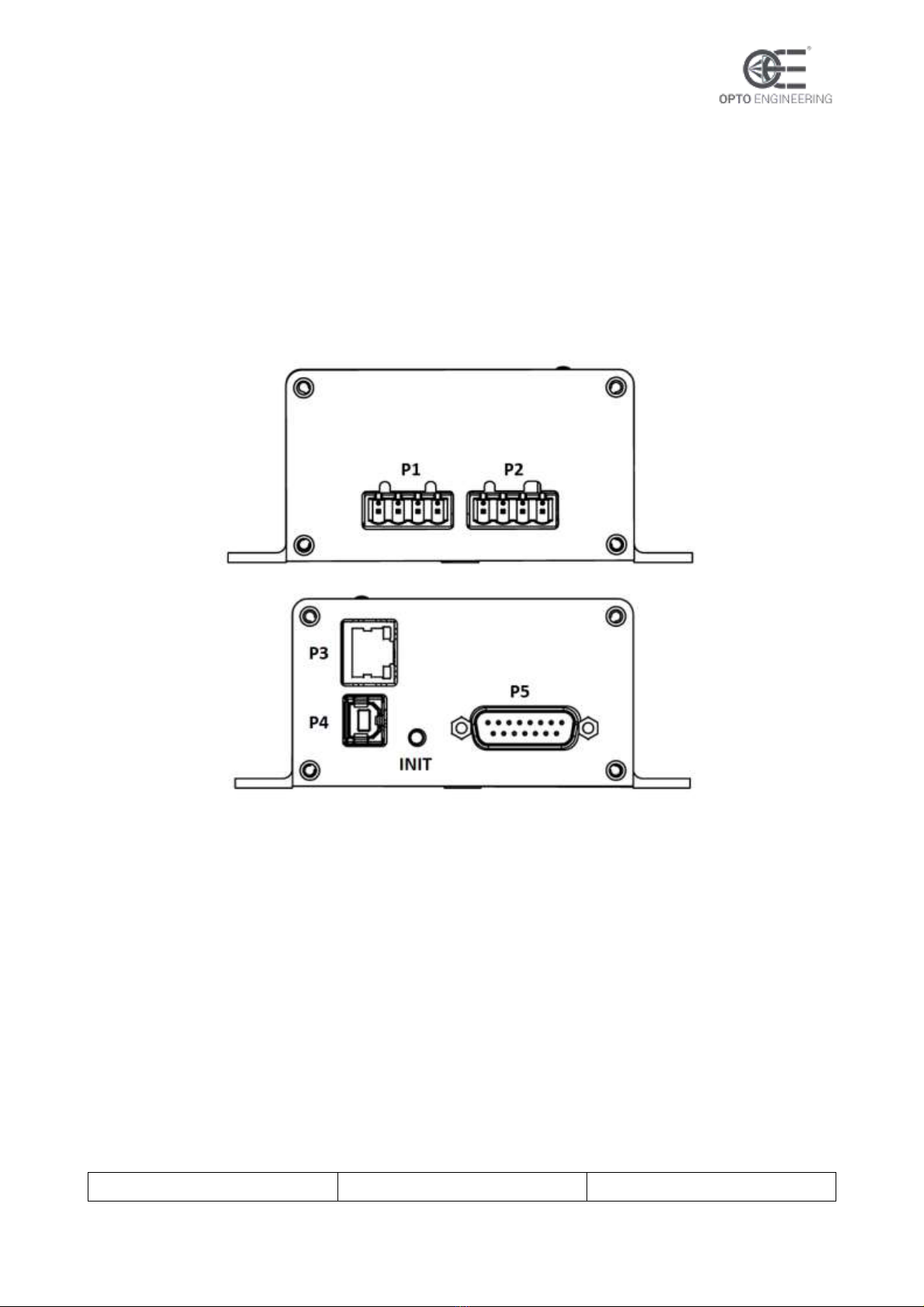

The controller can be set up using a PC with serial RS485 or Ethernet interfaces. Configurations are

saved in non-volatile memory so that the controller will resume operation after a power cycle.

4.1. Benefits of current control

Most LED manufacturers suggest their products to be driven using a constant current source, not a

constant voltage source. This is because, using a constant voltage driving, small variations in

temperature or voltage at the LEDs can cause a noticeable change in their brightness.

Brightness control with voltage is also very difficult because of the non-linearity of brightness with

voltage. On the contrary, the brightness is approximately linear with current, so by driving the LEDs

with a known current, intensity control is linear.

4.2. Operating mode

This strobe controller has two programmable, current-controlled light outputs. The two light outputs

can be used in pulsed or continuous mode.

In pulsed mode the light is switched on only when necessary. A digital input is used as a trigger

source. When a rising or falling edge on the trigger signal is detected the output is pulsed for the

programmed amount of time.

Using this technique, it is possible to obtain excellent steady images of moving objects. The camera

can be set for an arbitrary long exposure time and the light turned on for a shorter time, just enough

to freeze the motion. This helps to overcome the uncertainty issues usually related with integration

start which, to some degree, afflict most commercial cameras.

The delay from the trigger to the output pulse, the width of the output pulse and the intensity of the

output pulse are all independently configurable. The pulse delay can range from 0 µs to 1 s. The

pulse width can range from 1 µs to 1 s.

In continuous mode the light is always switched on, independently from the trigger signal. Using this

technique, the maximum current value for each channel has to be limited in order to prevent the

overheating of the controller.

The two output drivers in the controller can either operate in two modes: independent mode and

shared mode. In independent mode, the two light outputs are completely autonomous and currents

and timings are independent.

In the shared mode the two output drivers are interconnected. This results in twice the maximum

output current than in the independent mode. In the shared mode, the controller effectively behaves

as a single channel controller.

In either independent mode or shared mode there are two current ranges. In independent mode the

current ranges are:

Low current, up to 250 mA (with a resolution of 1 mA)

High current, up to 20 A (with a resolution of 20 mA)

In shared mode the current ranges are:

Low current, up to 500 mA (with a resolution of 2 mA)