奇菱光電股份有限公司 Chi Lin Optronics Corp.

Doc. No CS-72601

Version A3

Title

CHT-726 Level 1 Service Manual

Page

4 / 75

Contents

1. Purpose..........................................................................................................................5

2. Definition of service level.............................................................................................5

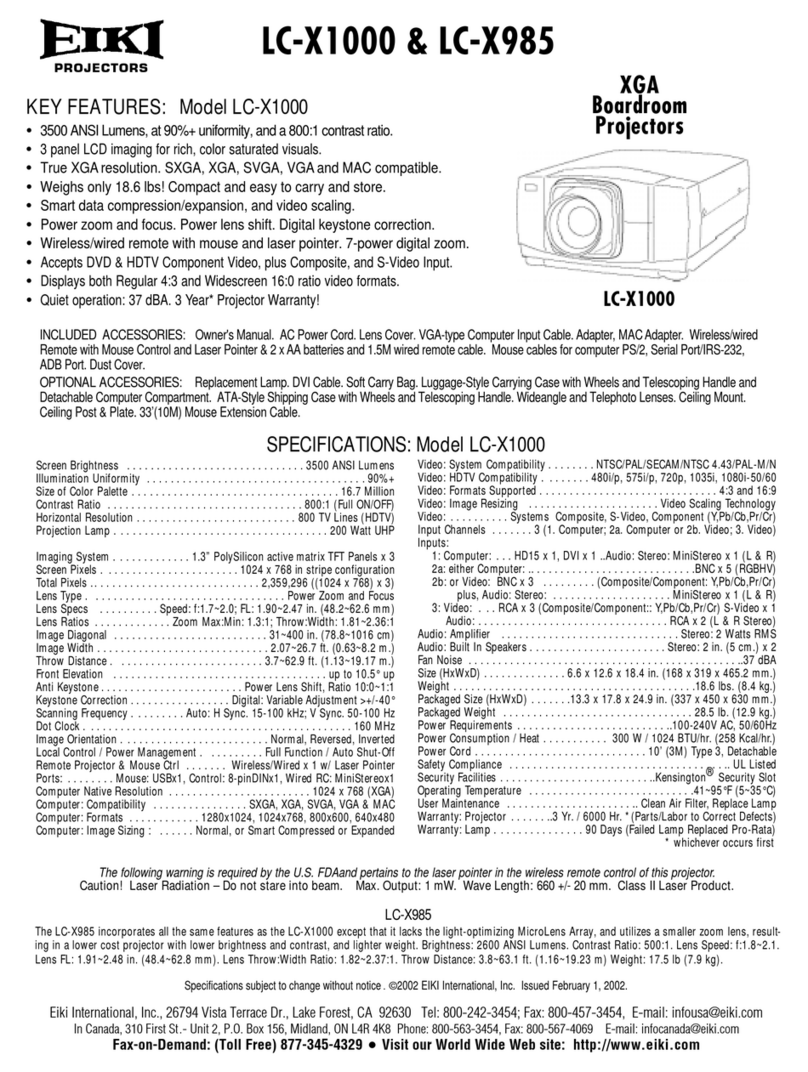

3. Specification..................................................................................................................5

4. Structure of the Product..............................................................................................6

4.1 I/O Interface ........................................................................................................... 6

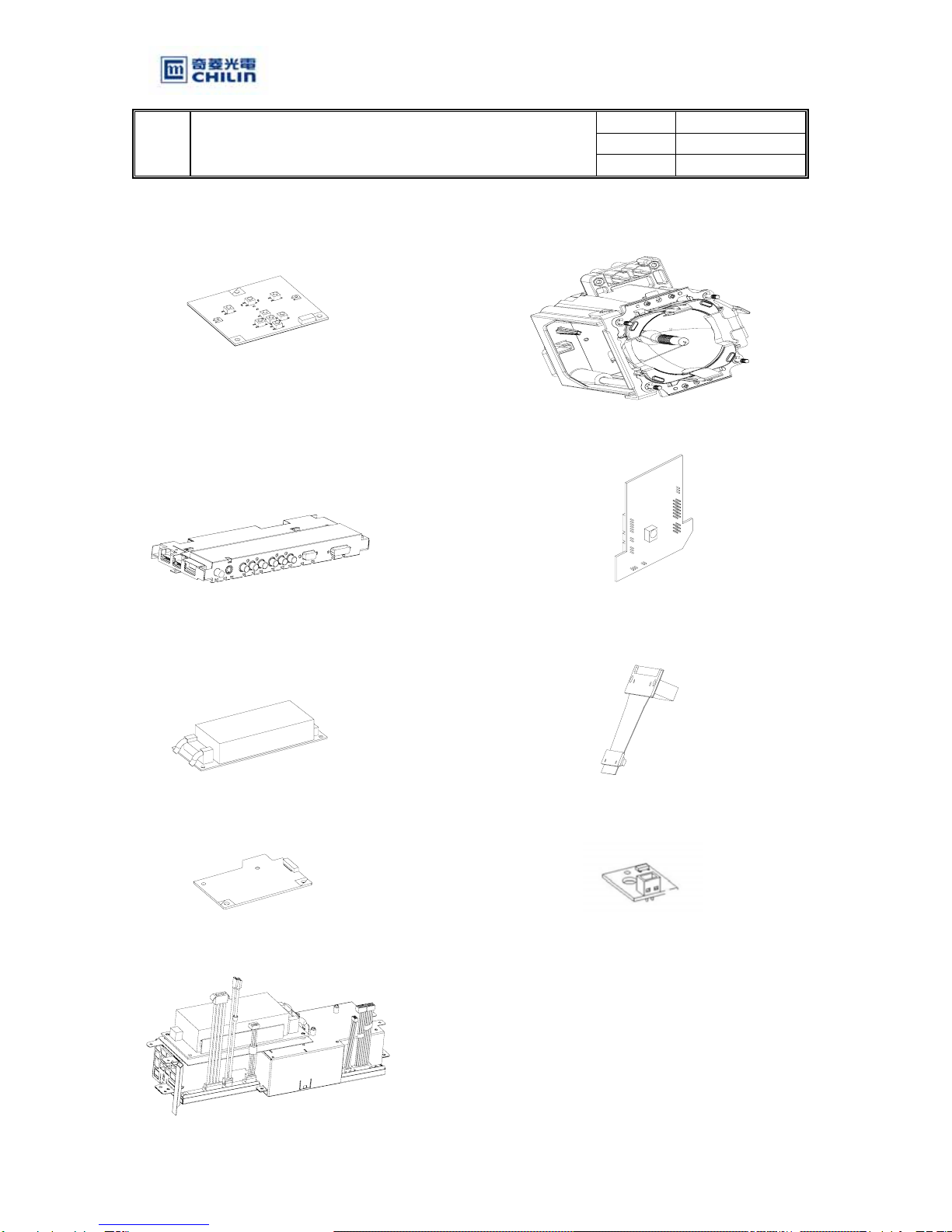

4.2 Exploded View (attached as Appendix II) ............................................................. 7

4.3 Detail description of parts shown in 4.2 Product exploded View.......................... 8

4.4 Composition of Level 1 Modules (Parts)............................................................... 9

5. Troubleshooting .........................................................................................................11

5.1 Troubleshooting Table ………………………………………………………….11

5.2 Block Diagram ………………………………………………………………….14

6. Service Mode...............................................................................................................15

6.1 Options: ................................................................................................................ 15

6.2.1 Video Formatter ........................................................................................... 15

6.2.2 DLP Vsync ................................................................................................... 15

6.2 Test Patterns:........................................................................................................ 16

6.2.1 DLP Test Patterns ........................................................................................ 16

6.2.2 Lens Checkerboard....................................................................................... 21

6.2.3 4 X 4 Checkerboard ..................................................................................... 21

6.2.4 Scaler Test Patterns ...................................................................................... 22

6.3 Adjust CW............................................................................................................ 23

6.4 CW Index ............................................................................................................. 23

6.5 VGA Auto Calibration ......................................................................................... 24

6.6 MST 9888 Comp YPbPr ...................................................................................... 24

6.7 AD9882 VGA RGB ............................................................................................. 24

6.8 SAA 7118............................................................................................................. 25

6.9 DLP RGB Gain Offset ......................................................................................... 25

7. Firmware Updade ......................................................................................................26

8. Replacement Procedure (Disassembly & Assembly)..............................................28

8.1 Replace The Lamp module .................................................................................. 28

8.1.1 Resetting Lamp Timer.................................................................................. 29

8.2 Replace Cooling Fans .......................................................................................... 31

8.2.1 Replace The Front Axial Fan ....................................................................... 33

8.2.2 Replace The Rear Axial Fan ........................................................................ 36

8.2.3 Replace The Blower Fan.............................................................................. 39

8.3 Replace The Keypad ............................................................................................ 48

8.4 Replace The Control Board.................................................................................. 51

8.5 Replace The Connection Board ........................................................................... 54

8.6 Replace The Video Module, The I/O Board, The Ballast, The Thermal Sensor,

and The Power Module ........................................................................................................ 57

8.7 Procedures for the video module adjustment....................................................... 71

Appendix I : Spare Parts List for CHT 726..........................................................................75