0-2 EP737 SERVICE MANUAL

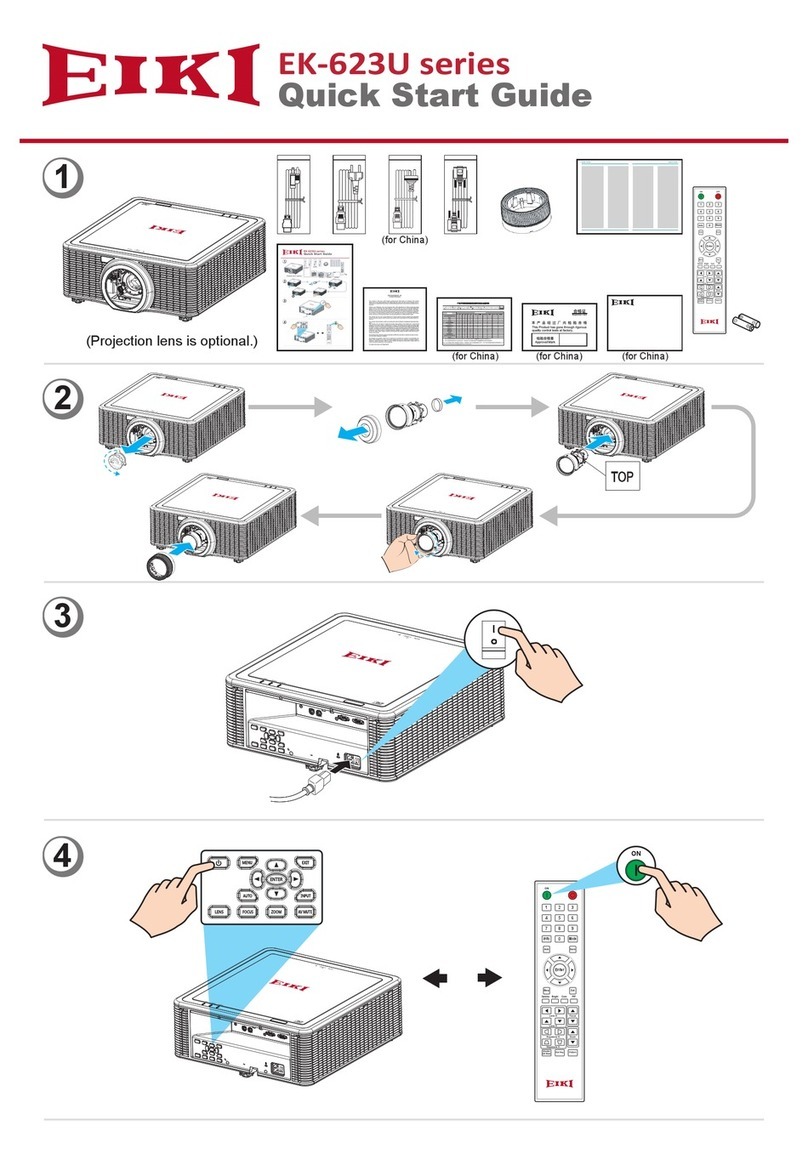

Introduction Fundamental Principle Mechanical Construction Procedure of Disassembly Function of Boards Specifications

Troubleshooting Function Test and Alignment Procedure Firmware Upgrading Procedure DDC Key-In Procedure Appendix

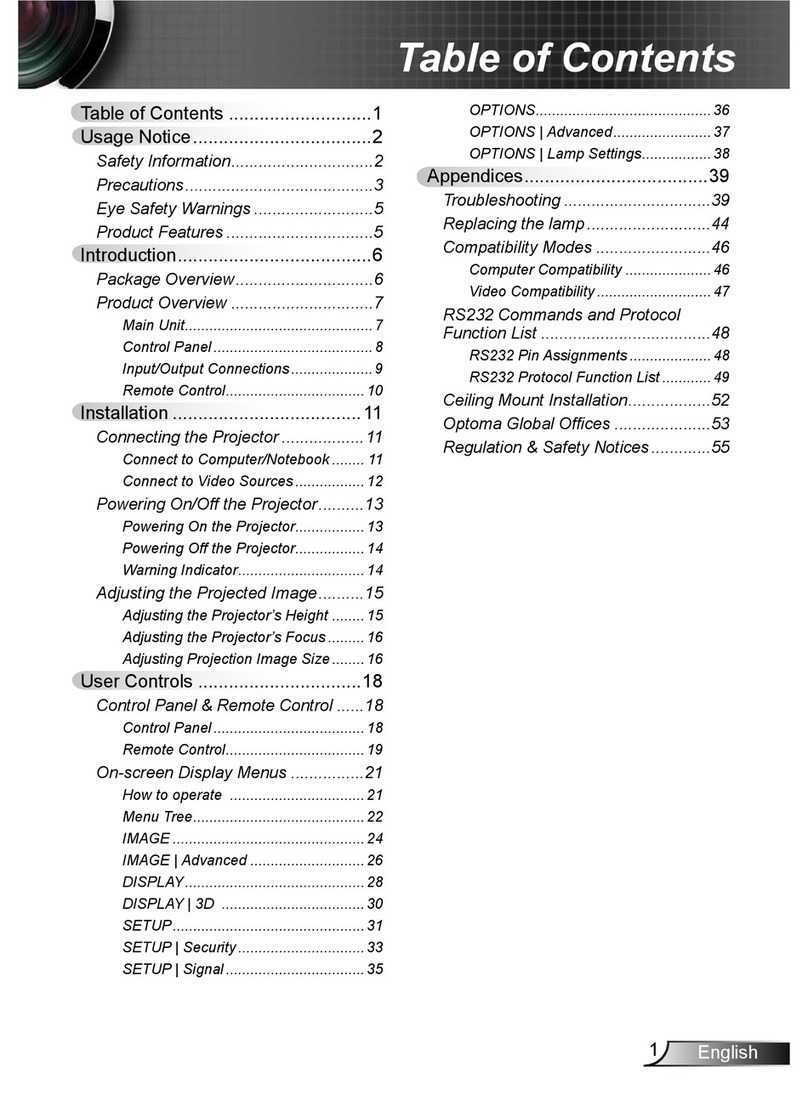

Introduction....................................................................................................................... 1-1

Product Highlights......................................................................................................................... 1-2

Technical Specifications................................................................................................................ 1-3

Fundamental Principle....................................................................................................... 2-1

Function Block Diagram................................................................................................................ 2-2

Optics............................................................................................................................................. 2-6

Mechanical Construction.................................................................................................... 3-1

Package Overview.......................................................................................................................... 3-2

Exploded Overview........................................................................................................................ 3-4

Recommendation Spare Parts List................................................................................................ 3-26

Procedure of Disassembly.................................................................................................. 4-1

Disassemble Lamp Module............................................................................................................ 4-3

Disassemble Top Cover and Keypad Board.................................................................................. 4-4

Disassemble Left Cover, Right Cover and I/O Bezel Module....................................................... 4-6

Disassemble Front Cover.............................................................................................................. 4-8

Disassemble Thermal Board and Main Board............................................................................... 4-10

Disassemble Ballast and Fan Module........................................................................................... 4-12

Disassemble DC-DC Board and Interlock Switch......................................................................... 4-14

Disassemble Engine, DMD and DMD Board.................................................................................. 4-15

Disassemble Color Wheel, Photo Sensor Board and Thermal Switch.......................................... 4-17

Disassemble Elevator Module....................................................................................................... 4-18

Function of Boards............................................................................................................. 5-1

DMD Board..................................................................................................................................... 5-2

Main Board..................................................................................................................................... 5-7

Keypad Board................................................................................................................................. 5-15

Thermal Board................................................................................................................................ 5-16

Table of Contents (I)