GN128-1536 Rev. - Orange Research Inc. Page 1 of 2

INSTRUCTIONS

Series 1536

DIFFERENTIAL PRESSURE INSTRUMENTS

Diaphragm Sensor

Your new Orange Research Differential Pressure Instrument is

a rugged instrument featuring simplicity of design to provide

dependable and efficient service. Because it is an instrument

it should be handled with care. Read all instructions carefully

before attempting to install the instrument.

CAUTION: Do not exceed maximum operating pressure

listed on instrument label. Use only fluids compatible

with wetted parts.

HOW IT WORKS

The instrument operates on the difference between two

pressures (delta-P). The sensing element is a spring biased

diaphragm which moves linearly in proportion to the difference

between two basic pressures. A magnet on the HI pressure

side of the diaphragm/magnet assembly moves with the

diaphragm and rotates a follower magnet located adjacent to

the pressure cavity. The gauge pointer is located at the end of

the rotary magnet shaft and rotates with the magnet to provide

gauge readings proportional to differential pressure variations.

This is accomplished by coupling the forces between two

adjacent magnets through a solid wall.

Note:This instrument will provide ±2% accuracy full scale.

INSTALLATION

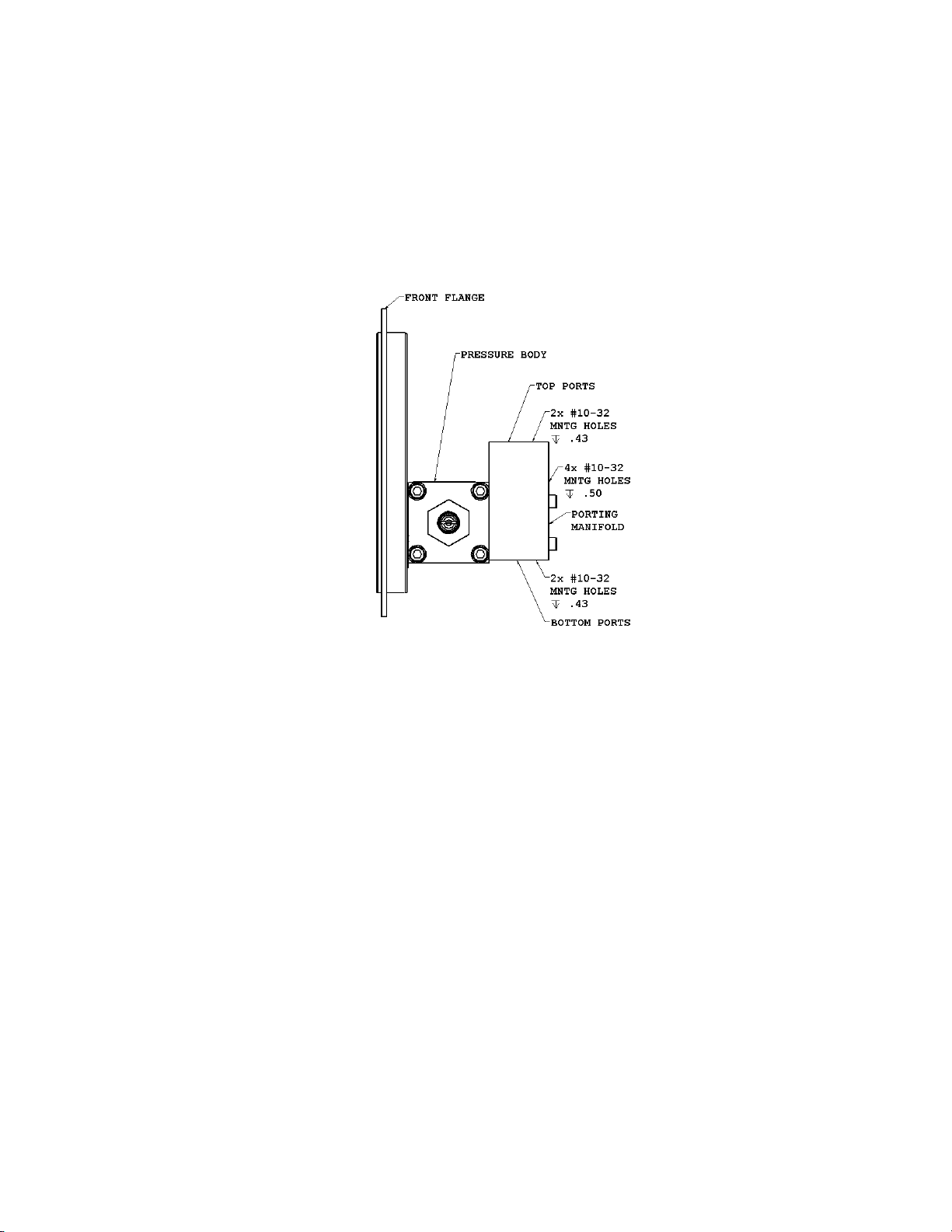

This gauge is a 1516 with a porting manifold mounted to the

back. The mounting holes on the back/bottom and the process

ports mimic those found on the Barton 227C gauge. In fact the

relative position of the mounting holes and the process ports is

exactly the same as the Barton gauge, allowing you to remove

the Barton gauge and install this unit in minutes without

changing the position of the mounting screws and piping.

If you have a Barton mounting bracket, you can reuse it on our

gauge.

The gauge can be mounted to a bracket using the mounting

holes on the back of the pressure body, or panel mounted

using the three holes on the dial case front flange.

Most differential pressure gauges have two pressure ports,

one for high pressure and one for a low pressure connection.

Model 1536 has four ¼ inch FNPT ports. Two are high

pressure ports and two are low pressure ports. The ports are

marked HI for high and LO for low.

HI-Left ports –standard

The standard configuration, called Hi-Left, has the two high

pressure ports on the left and two low pressure ports on the

right, as you read the dial

Hi-Right ports –no charge option

An optional Hi-Right configuration has the high pressure ports

on the right and the low pressure ports on the left, as you read

the dial.

High Pressure on wrong side?

If you have received a gauge with the porting reversed for your

setup, another porting manifold with opposite porting can be

sent to you. You can easily retrofit the new porting manifold in

the field. Please contact Orange Research to have this sent to

you.

To retrofit your unit with another porting manifold, remove the

four bolts on the back of the unit holding the manifold. (Do not

remove the four bolts on the side of the unit!) Remove the two

O-rings and assemble the new porting manifold using the

same four bolts and the new O-rings. Be sure to lightly grease

the new O-rings so they slide into position properly.

The Hi-Left porting manifold on the back is scribed with an “A”

on the top, while the Hi-Right porting manifold is scribed with a

“B”. Please refer to the necessary porting manifold as Hi-Right,

Hi-Left or as “A” or “B” so we can be sure to send you the

proper manifold. Please also identify the type of O-ring

material used on your unit, since we will need to send two

more new O-rings, and they will have to match what you have

now.

Only two of the four ports are required to measure differential

pressure. The additional high and low ports can be used for

bleed ports, to connect a pressure gauge or other instrument,

or simply to connect additional piping.

Two port plugs are supplied with each unit. Install them in any

ports not being used in your installation. Teflon tape should be

used on all port connections. Two or three wraps of Teflon

tape are recommended.

If you have selected the ½ inch NPT ports option, you will have

received four ¼ inch to ½ inch adapters. Install them in as

many ports as required with Teflon tape.

- For a Brass body the adapters are Brass

- For an Aluminum body the adapters are SS

Filters

For filter applications, the high pressure port would be piped to

the inlet of the filter and the low pressure port would be piped

to the outlet of the filter.

Cryogenic Tanks

In the case of a cryogenic tank the high pressure port would

be mated to the bottom of the tank while the low pressure port

would be mated to the top of the tank, called the vapor space

or the ullage.

DP Flow

For dp flow measurement, the high pressure port would be

installed on the inlet of the primary flow element while the low

pressure port would be installed on the outlet of the flow

element.