INTRODUCTION

The principal use of your new 418 Limiter is to condi-

tion arbitrary complexaudio signals (not just single

tracks, although the 418 may be used with these, too)

in such away that they can be recorded on tape or opti-

cal film without overload, excessive noise, or distortion

due to excessive high frequencies. In order to do this

while introducing minimal artifacts into the signal, the

418 incorporates ahighly refined program-controlled re-

lease time circuit, as well as aseparate high-frequency

limiter which can control the high frequencies present in

the program on an instantaneous basis without distortion

and without disturbing the basic program loudness.

The release time and high-frequency limiter are both

adjustable by the user in order to obtain the desired

amount of high-frequency control, level control, com-

pression, and density augmentation .The controls have

been arranged to minimize the probability of audible

side-effects of an undesirable nature regardless of their

settings

.

Some uses of the 418 include: (1) mixing through

while doing multitrack reductions in order to save time

while doing radio commercials, demo sessions, and the

like; (2) conditioning recorded program material so that

it can be copied onto cassette or low-speed tape without

excessive hiss and/or high-frequency distortion; (3) trans-

fering from magnetic to optical film; (4) transferring from

disc to 7.5 ips tape cartridge in broadcast stations; (5) re-

cording production work through in broadcast production

studios; and (6) transferring from tape to disc (with certain

limitations —see OPERATING INSTRUCTIONS). Other

applications will doubtless suggest themselves to the

creative engineer

.

The 418 is not rigorously RFI/EMI shielded, and its

output contains substantial amounts of fast overshoots.

It is therefore specifically not recommended for driving

broadcast transmitters. Orban Associates Division manu-

factures aline of devices, the OPTIMOD-FM and the

OPTIMOD-AM, specifically designed for this purpose.

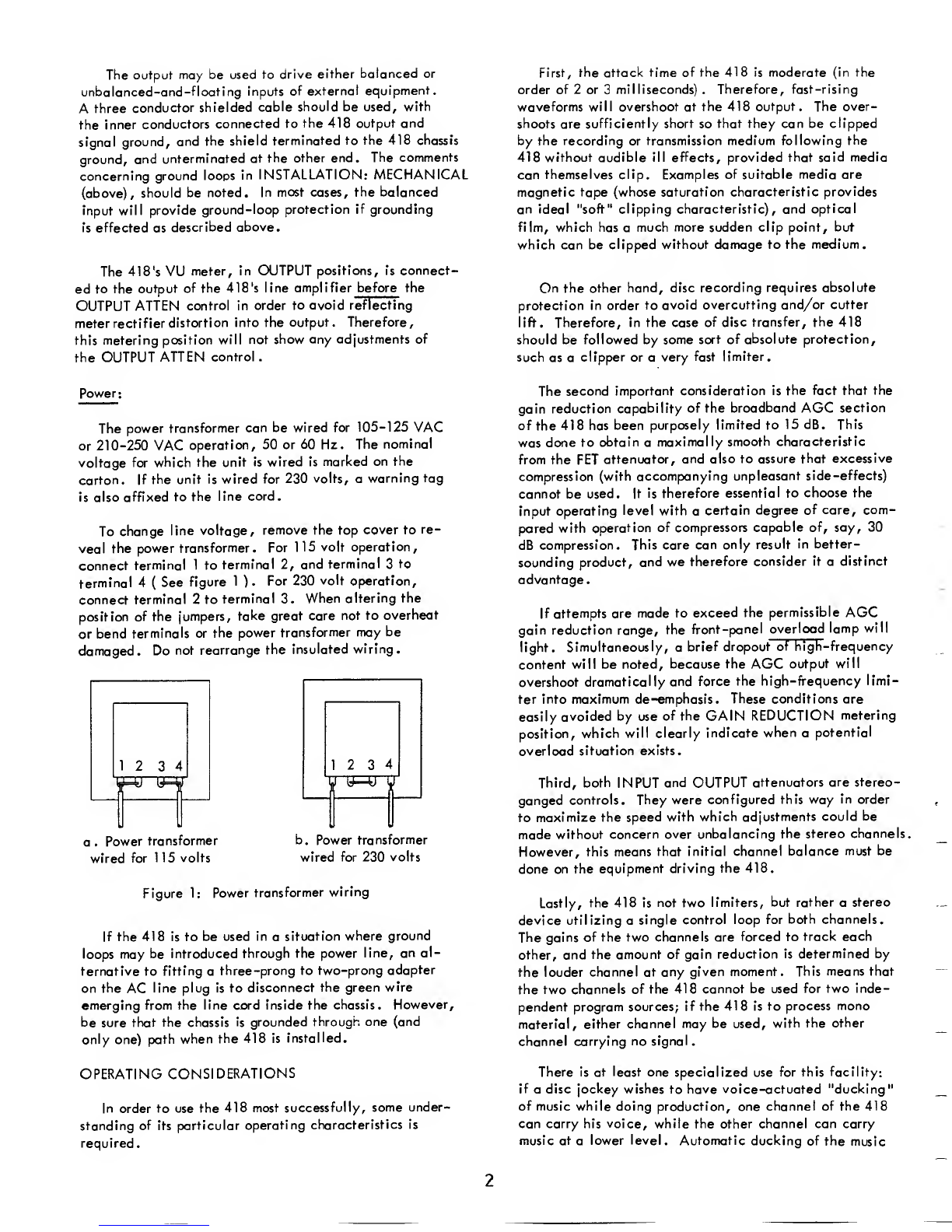

INSTALLATION: MECHANICAL

The 418 Limiter is designed to mount in astandard 19"

(48.26 cm) rack, and requires 3.5" (8.89 cm) of vertical

space. All operating controls are accessible from the

front. The fuse, AC line cord, and audio connections

are made from the rear. The audio connects to aJones

140-type barrier strip (^5 screw), and connections can

be made by means of spade lugs or afanning strip, in

those cases where quick connects/disconnects are required.

In arack mount installation, the 418 will pick up its

chassis ground from the rack. Be sure to measure the re-

sistance from chassis to rack after installation and correct

any high-resistance situations before proceeding. It may

be necessary to scrape the paint from the rack and/or the

rear of the panel in order to effect an adequate ground.

It is advisable to make sure that the rack is grounded to

some earth ground simultaneously. Grounding of racks

and other equipment to power line conduit grounds as a

sole means of grounding often creates troublesome prob-

lems.

In rack -mounting the 418, very strong AC magnetic

fields should be avoided because these can introduce hum

into the input transformers. In addition, the 418 should

not be mounted directly over equipment producing large

amounts of heat, like vacuumtube power amplifiers.

Ambient temperature should not exceed 45°C (11 3°F

)

when the 418 is powered.

If the 418 is rack-mounted, the jumper on the rear

barrier strip connecting terminal 7(signal ground)

to terminal 8(chassis ground) should be removed to

avoid ground loops. If the 418 is used in aportable situ-

ation, this jumper should be retained in order to assure

that the chassis is grounded. When the jumper is retained,

it is advisable to terminate the line cord with athree-

prong to two-prong AC adapter in order to avoid intro-

ducing ground loops through the AC power line grounding

system. The center (ground) prong on the 418 line cord

(green wire) is connected directly to the chassis.

INSTALLATION: ELECTRICAL

Input;

The input of the 41 8A is a100K ohm balanced bridging

input. It is synthesized by means of an electronic differ-

ential amplifier; no transformer is used. Absolute input

clipping occurs at +21 dBm; higher levels require use of an

external balanced pad. With the INPUT ATTEN full clock-

wise, -10 dBm will produce 10 dB gain reduction.

It is important that both (+) and (-) inputs be driven

by asource impedance of 600 ohms or less in order to

assure best "common mode rejection" (i.e., ground loop

hum rejection). If the device driving the 41 8A has a

balanced output, the two output leads should be driven

directly into the (+) and (-) inputs of the 41 8A. If the

device driving the 41 8A has an unbalanced output, it

snould also be connected to the 41 8A with atwo conductor

shielded cable. The black wire should be connected bet-

ween the driving device's signal ground and the 418A's

(-) input. The second wire should be connected between

the driving device's output and the 418A's (+) input.

This arrangement takes maximum advantage of the hum-

reducing ability of the 418 A's balanced input. In either

case, the shield of the interconnecting cable should be

connected to chassis ground at one end only.

No special RF suppression techniques have been used

in the 418A. If RF interference is experienced in high RF

fields, we suggest bypassing audio inputs, outputs, and the

power line to chassis ground through 0.001 mfd ceramic

capacitors with short as possible leads. Be sure that the

voltage rating of the power line bypass capacitor is at least

1.6 kV, and that bypassing occurs after the fuse to avoid

apotential fire should the capacitor short .Because the

chassis metalwork has not been designed to be rigorously

RF-tight, it is unlikely that the 418A could be operated

immediately adjacent to atransmitter. In abroadcast

production studio, sufficient RF suppression usually exists

so that successful operation can be easily obtained.

Output:

The output of the 418 is unbalanced, and follows the

OUTPUT ATTEN control, which is configured as astandard

potentiometer. Maximum output resistance occurs with

this control at 12 o'clock; in this case, the output resis-

tance is approximately 400 ohms. Maximum available

level is +1 3.4 dBm

.