ORBINOX CANADA, ORBINOX USA, ORBINOX BRAZIL, ORBINOX CHILE, ORBINOX PERU, ORBINOX SPAIN, ORBINOX UK, ORBINOX FRANCE, ORBINOX GERMANY, ORBINOX INDIA, ORBINOX CHINA, ORBINOX S.E.A.

ORBINOX reserves the right to change specifications without notice

In most cases, the operating floor level is located substantially

higher than the opening. In order to be able to operate the gate,

stem extensions are necessary. Stem guides are used to limit the

“unsupported” length of the stem extension in order to avoid any

buckling failure. The stem guide has a HWMPE guide to reduce

friction between the guide and the extension

NON-RISING STEM CONFIGURATION.

As standard, non-rising stem gate configurations are used with self-

contained frame designs. Therefore, the stem extension does not

support the axial load (only torque) and less wall brackets are

required. As a general rule, a stem guide should be installed every

10 feet (3 meters) of unsupported stem extension.

RISING STEM CONFIGURATION

As standard, rising stem gate configurations are used with open-

frame designs. Therefore, the stem extension has to support the

axial load when the gate is operated. In consequence, the use of

stem guides is critical to avoid any buckling failure. As a general

rule, a stem guide should be installed every 6½ feet (2 meters) of

unsupported stem extension.

INSTALLATION, OPERATION AND MAINTENANCE

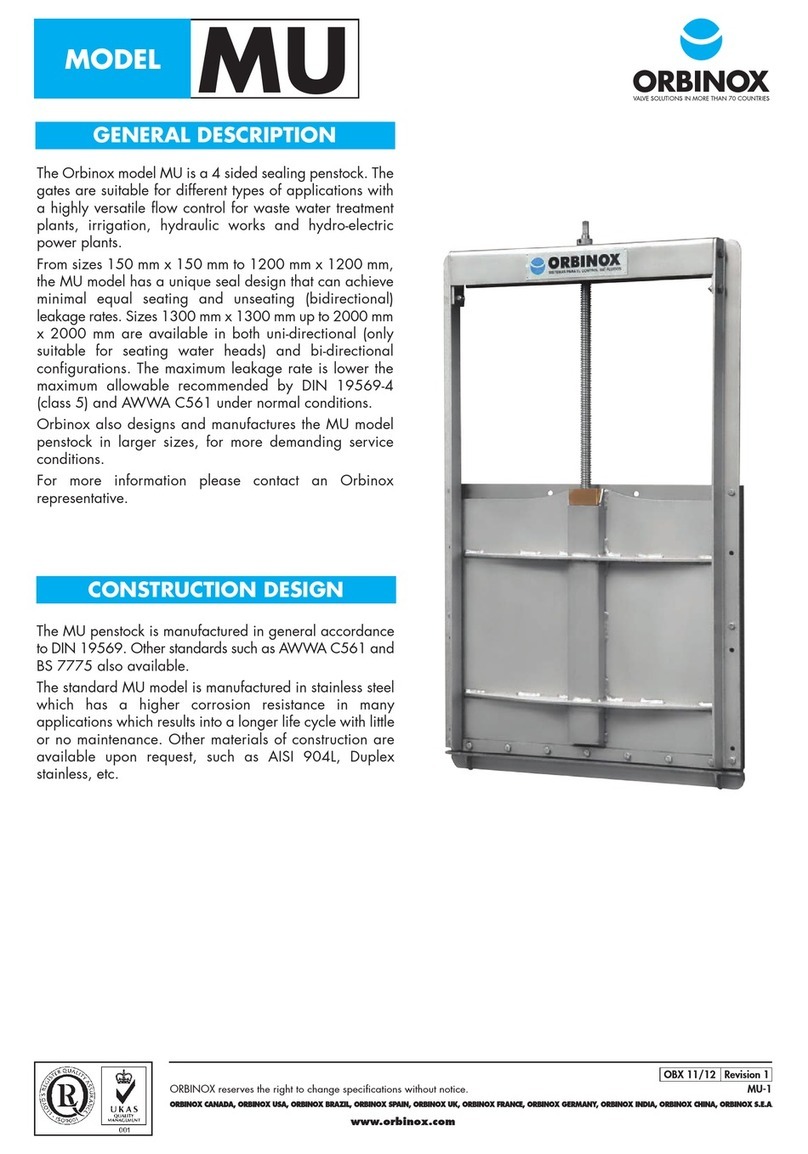

Slide Gate

(Rising Stem, Open Frame)

This section briefly describes the installation, operation

and maintenance of MU Slide Gates. For more detailed

information please refer to the “MU IOM Manual”

INSTALLATION:

ORBINOX MU Slide Gates are installed by means of

anchor bolts. Depending on the size and working

conditions they shall be either of the mechanical or

chemical type (see table below). In order to avoid

leakage between the concrete wall and the frame,

ORBINOX recommends the use of construction sealant

equivalent to Sikabond Construction Sealant (200ml

per meter of opening perimeter)

The minimum concrete strength shall be 3,000PSI (20.7

MPa). The concrete construction tolerance (flatness, levelness

and plumbness) shall be in accordance to ACI 117-10. For

detailed information about type, size and quantity of the

required anchor bolts for installation, please refer to the

notes on the “General Arrangement Drawing”

MAINTENANCE AND OPERATION:

The ORBINOX MU Slide Gates need practically no

maintenance. The stem should be kept lubricated and seals

should be replaced if damaged. The MU Slide Gate is

closed by applying a clockwise rotation. Applying excessive

force on the operator when closing the gate may cause

damage to the stem

Recommended (Hilti or

equivalent)

6”x 6” -48”x48”

(150mmx150mm-1200mmx1200mm)

Seating and Un-Seating

(Bi-Directional)

Wall Mount: Stud Type

Mechanical

Anchor Bolts and Bolt Type

Mechanical Anchor Bolts

Hilti “Kwik 3”

& Hilti “HSL”

52x 52”-160”x160”

(1300mmx1300mm-4000mmx4000mm)

Seating and Un-Seating

(Bi-Directional)

Embedded in concrete:

Optional wall mount + chemical

anchor bolts

52x 52”-160”x160”

(1300mmx1300mm-4000mmx4000mm)

Seating

(Uni-Directional)

Wall mount: Stud Type

Mechanical Anchor Bolts

Stem Guide & Slide Stopper