6

7. Running and parameter setting ....................................................................Page 28

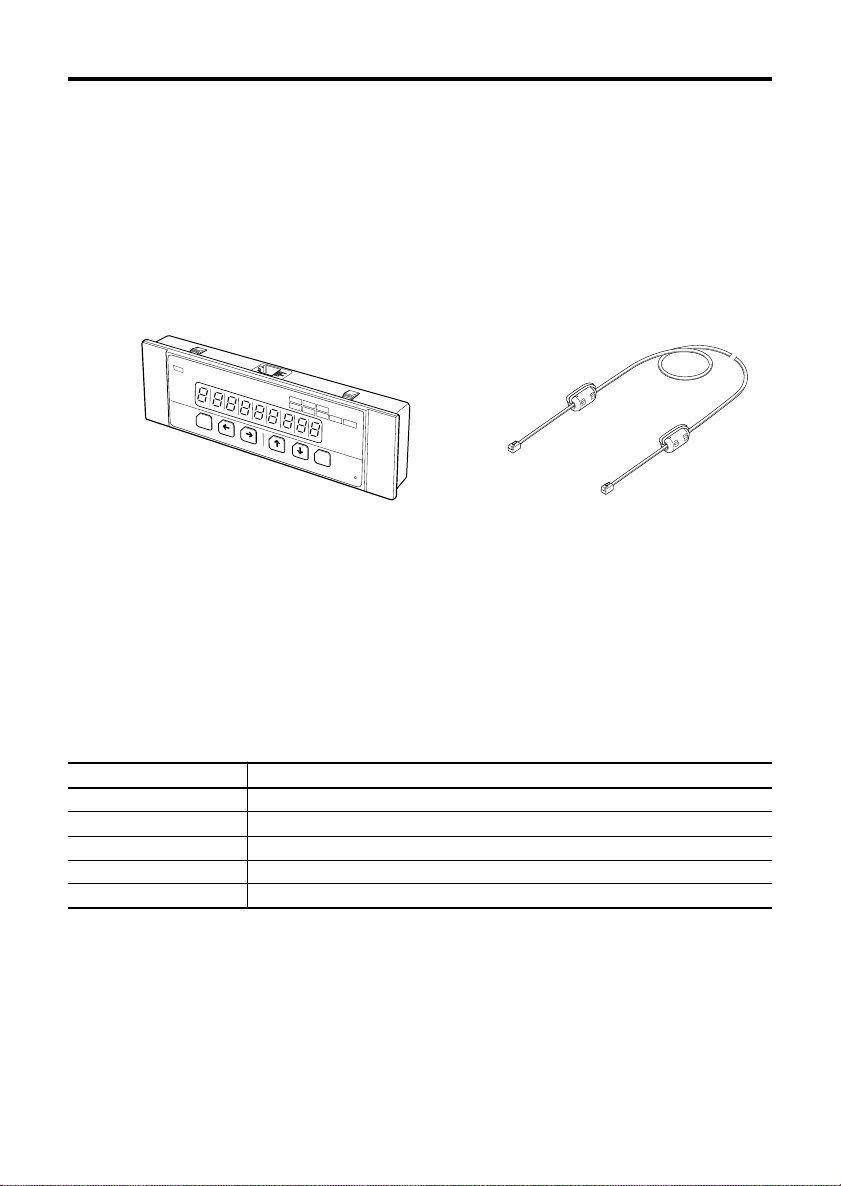

7.1 Dater setter OPX-1 ................................................................................Page 28

7.1.1 Connection......................................................................................Page 28

7.1.2 Name of individual components and function ................................. Page 29

7.1.3 LED display.....................................................................................Page 29

7.2 Data setter mode ...................................................................................Page 30

7.3 Monitor mode ......................................................................................... Page 30

7.3.1 Speed..............................................................................................Page 32

7.3.2 Position counter ..............................................................................Page 32

7.3.3 Torque.............................................................................................Page 32

7.3.4 Alarm code......................................................................................Page 32

7.3.5 Alarm history ...................................................................................Page 32

7.4 Program mode .......................................................................................Page 33

7.4.1 Selector...........................................................................................Page 34

7.4.1.1 Control mode ..........................................................................Page 35

7.4.1.2 Analog input ............................................................................Page 35

7.4.1.3 Torque limit .............................................................................Page 35

7.4.1.4 KBL-compatible mode (Enabled only in speed control mode) Page 35

7.4.1.5 Slow start and slowdown time................................................. Page 36

7.4.1.6 Output signal (BUSY/TLM) output switching........................... Page 36

7.4.1.7 Direction of return to mechanical home position..................... Page 36

7.4.1.8 Continuous operation (scan)................................................... Page 36

7.4.1.9 Initial display ...........................................................................Page 36

7.4.2 Operation data ................................................................................Page 37

7.4.2.1 Movement ...............................................................................Page 37

7.4.2.2 Rotation direction in continuous operation ..............................Page 37

7.4.2.3 Electrical home position offset ................................................Page 37

7.4.2.4 Speed of rotation..................................................................... Page 38

7.4.2.5 Torque limit .............................................................................Page 38

7.4.3 Control parameter ...........................................................................Page 39

7.4.3.1 Digital torque limit used in common ........................................Page 39

7.4.3.2 Slow start time ........................................................................Page 39

7.4.3.3 Slowdown time ........................................................................Page 39

7.4.3.4 Speed reduction ratio (for speed display) ...............................Page 39

7.4.4 Adjustment parameter.....................................................................Page 40

7.4.4.1 Position loop proportional gain................................................ Page 40

7.4.4.2 Speed loop proportional gain ..................................................Page 40

7.4.4.3 Speed loop integral gain .........................................................Page 40

7.4.4.4 Positioning completion width................................................... Page 40

7.4.5 Copy function ..................................................................................Page 41

7.4.5.1 Loading ...................................................................................Page 42

7.4.5.2 Saving .....................................................................................Page 42

7.4.5.3 Verifying ..................................................................................Page 42

7.4.5.4 Initialization .............................................................................Page 42

7.4.5.5 Cancel ..................................................................................... Page 42

7.5 Test mode .............................................................................................. Page 43

7.5.1 Jog operation preparation ...............................................................Page 43

7.5.2 Jog operation .................................................................................. Page 43