Screens

Calibrate

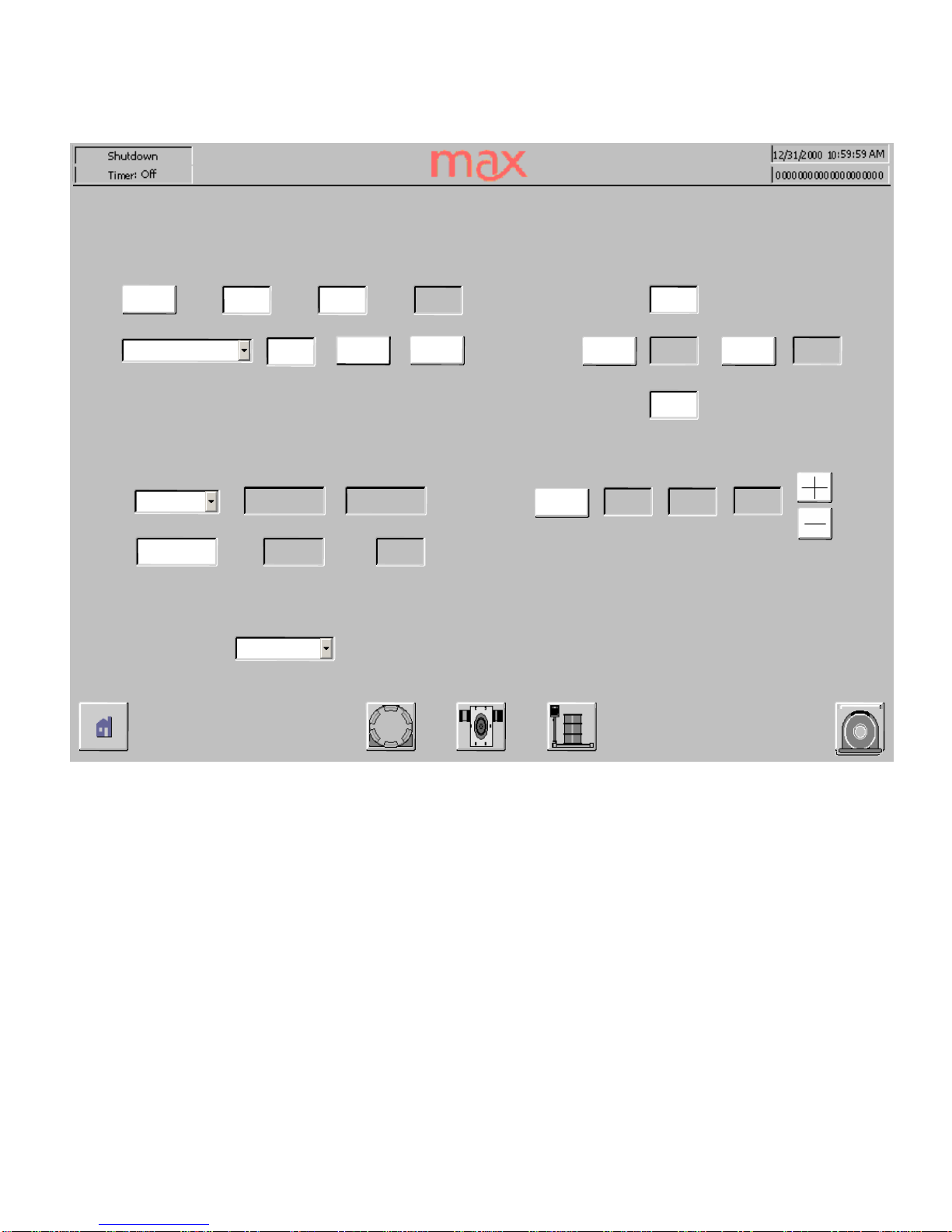

The Calibrate screen is used to calibrate the flow meter and pump output for an individual

component,

line

pressure can

a

lso

be monitored and controlled from the calibrate screen.

NOTE:

You cannot enter the calibration screen during a pour, flush or material purge of the

mix head. Entering or leaving this screen will set all pour valves to “N”

to prevent

unintentional pour

ing of chemicals.

Before any short duration shots are performed, the pour and recirculation pressure

need to be

balanced. Establish the flow rate you intend to use. Cycle the pour valve and compare the

displayed values. In automatic mode, the PLC will b

alance the two values. In manual mode,

you can use the +/

-

keys to adjust the recirculation pressure until it matches the pour pressure.

A

calibration check

should be done for both the Flow Control choice and the Pump Control

choice. (

In systems that do

not have flow meters

, only the Pump Control choice will be valid.)

The intended flow rate for this component should be entered as the Set Point. Select a pour

time that will create a sample of at least 100 grams. Push the “start pour” button on the mix

head control box, collect and weigh the sample. Input the sample weight into the “Measured

Pour” field and hit the “Calibrate” button.

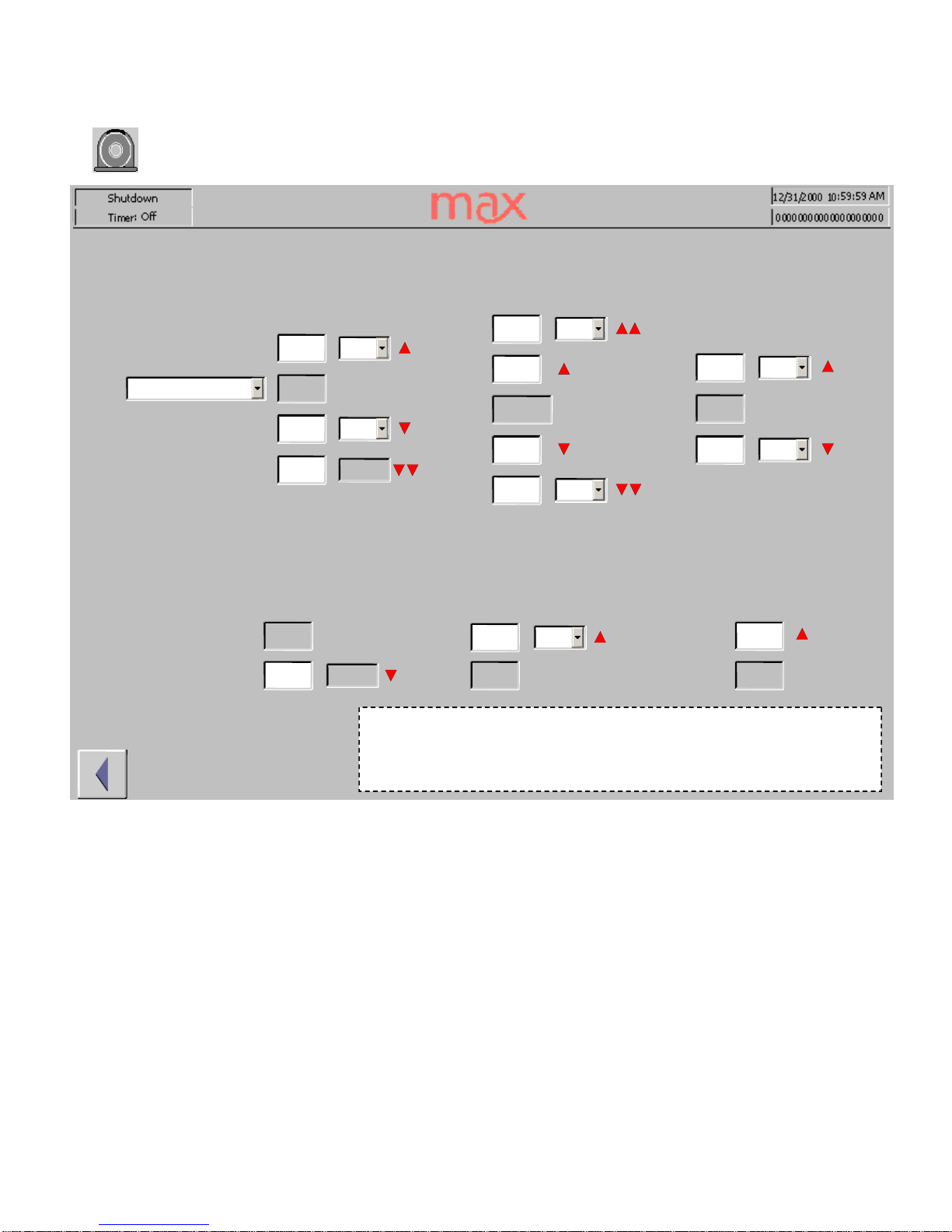

Calibration values that exceed the

previously defined maximum Flow or Pump rate, or that

change the density value by mo

re than 10% will trigger a warning message. Double check the

weight and entered value before accepting the adjustment.