Table of Contents

WattMaster Controls, Inc.

8500 NW River Park Drive · Parkville, MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

Form: OR-PTLNK3N2-TGD-01E

Copyright October 2016 WattMaster Controls, Inc.

N2®is a registered trademark of Johnson Controls, Inc.

FieldServer is a Registered Trademark of FieldServer Technologies, Milpetas, CA

Windows®XP, Vista, 7, 8 & 10 are registered trademarks of Microsoft Corporation.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

This document is subject to change without notice.

General Information......................................................................................................................................... 3

Hardware Specifications ..............................................................................................................................................................3

System Requirements..................................................................................................................................................................3

Dimensions and Components......................................................................................................................................................4

Quick Start Guide ............................................................................................................................................ 4

Connection and Wiring Information ................................................................................................................ 5

Configuring the PT-Link II Controller............................................................................................................... 6

PT-Link II Hardware Connection ..................................................................................................................................................6

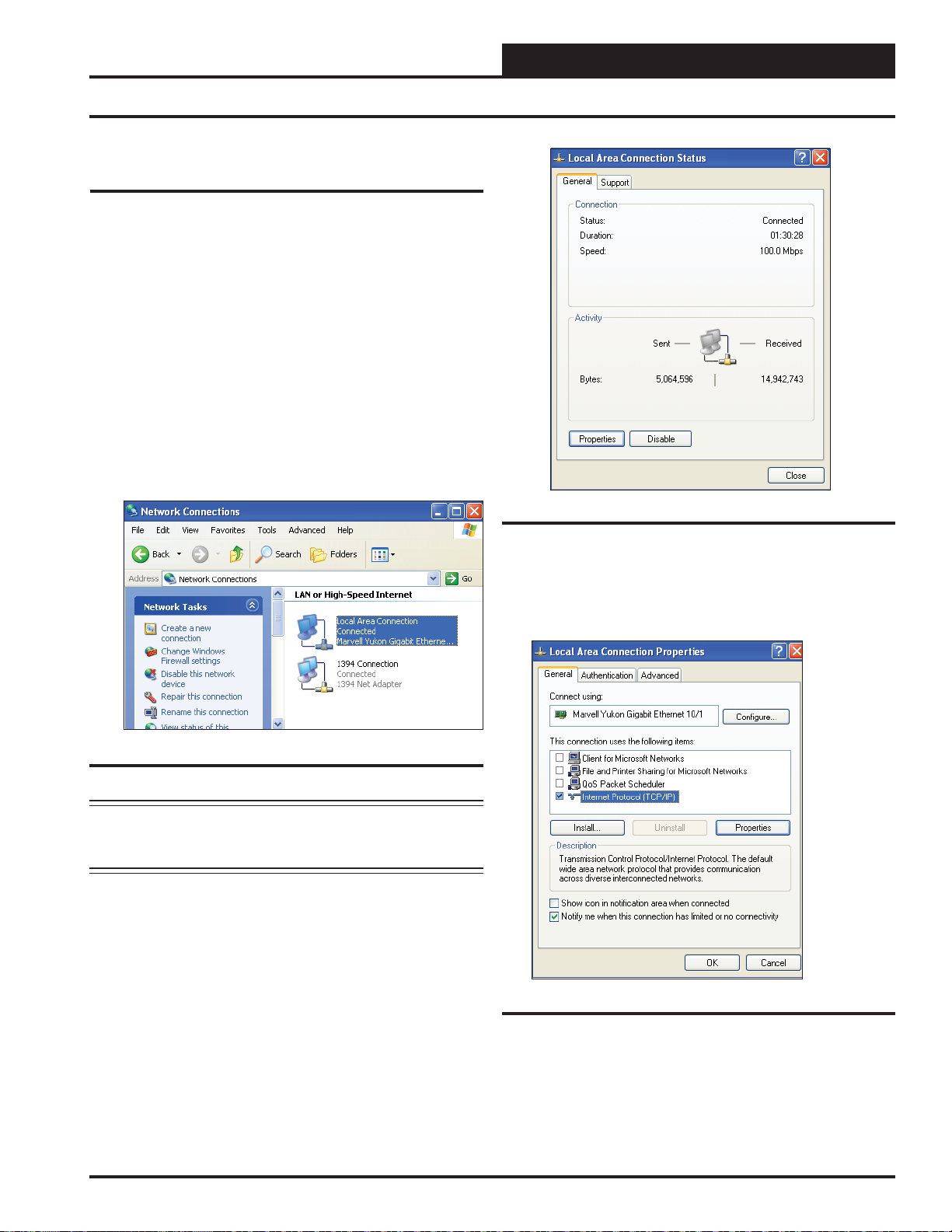

Computer IPAddress Set-up for Windows NT & XP....................................................................................................................7

Computer IPAddress Set-up for Windows Vista, 7, or 8..............................................................................................................8

Connecting to the PT-Link II using Field Server’s Graphical User Interface................................................................................9

Updating the Configuration File (config.csv) ................................................................................................................................9

Troubleshooting the PT-Link II Controller..................................................................................................... 12

Addressing WattMaster Devices in an N2®Network..................................................................................................................12

PT-Link II Board LEDs................................................................................................................................................................13

ProtoCessor Module LEDs - OE368-23N-N2-3..........................................................................................................................14

Updating the PT-Link II Controller................................................................................................................. 15

Data Arrays.................................................................................................................................................... 19

Table 2: VCM-X WSHP (Tulsa) Data Array for Field Server......................................................................................................19

Table 3: VCM-X WSHP (Coil) DataArray for Field Server........................................................................................................19

Table 4: VCM-X Data Array for Field Server..............................................................................................................................20

Table 5: SA Controller Data Array for Field Server....................................................................................................................20

Table 6: VCM Data Array For Field Server................................................................................................................................21

Appendix A - FieldServer’s Graphical User Interface Reference Guide....................................................... 22

Appendix B - VCM-X WSHP N2 Parameters................................................................................................... 25

Appendix C - VCM-X N2 Parameters ............................................................................................................. 27

Appendix D - SA Controller N2 Parameters .................................................................................................. 34

Appendix E - VCM N2 Parameters................................................................................................................. 37