5

Operation

TheBreezeisaself-containedunit,whichcontrolsuptotwoprimaryandtwosecondarypumps

togetherwitha3or4-portvalvetoprovidehotwater.Whenthesystemisttedwithtwoprimary

pumpstheyareoperatedonasharedduty-standbycyclewithautomaticchangeoveronpumpfailure.

a) Remote Switch or Building Management System Control

TheBreezewillbeturnedonwhencontactsconnectedtotheRemote Enable terminals are

closed.Thisallowstheusertocontrolthetimeofdaywhenhotwaterwillbeavailable.

When the contact is open the system is turned off.

b) Internal Time Clock Control

ForthisfunctiontoworktheTimeclockfunctionshouldbeturnedon(seeSetUp)andthe

Remote Enable terminals should be linked.

UnderTimeclockcontroltheBreezewillbeturnedonandoffatpresettimesoftheday.

Uptotwoonandtwoofftimescanbeprogrammedforeachdayoftheweek.

Thesystemcanbere-activatedafterithasautomaticallyswitchedoffbypressingthe

Value Increase (7)pushbutton.Eachpressofthispushbuttonwilladd30-minuteincrementsto

atotal,whichisshownintheTime/Alarmwindow.PressingtheValue Decrease (9) push button

willsubtract30-minuteincrementsfromthetotaltime.

Thetimevaluecountsdownandwhenthetimeshownhaselapsed,theunitwillrevertto

normal time clock operation.

c) Remote Switch and Internal Time Clock Control

Forthisfunctiontowork,theTimeclockfunctionshouldbeturnedon(seeSetUp)anda

remote ControlswitchshouldbeconnectedtotheRemote Enable terminals.

UnderTimeclockcontroltheBreezewillbeautomaticallyturnedonandoffatpreset

timesoftheday.Uptotwoonandtwoofftimescanbeprogrammedforeachdayoftheweek.

When contacts connected to the Remote Enable terminalsareopenedtheBreeze-Platewillbe

turned off.

When remotely enabled and the system has turned off under time clock control, it can be

re-activated by pressing the Value Increase (7)pushbutton.Eachpressofthispushbuttonwill

add30-minuteincrementstoatotal,whichisshownintheTime/Alarmwindow.Pressingthe

Value Decrease (9)pushbuttonwillsubtract30-minuteincrementsfromthetotaltime.

Thetimevaluecountsdownandwhenthetimeshownhaselapsed,theunitwillswitchoffand

reverttonormaltimeclockoperation.However,whenthesystemhasbeenturnedoffunder

remote control, it cannot be re-activated by pressing the Value Increase (7) push button.

Switchonviaswitch(16)

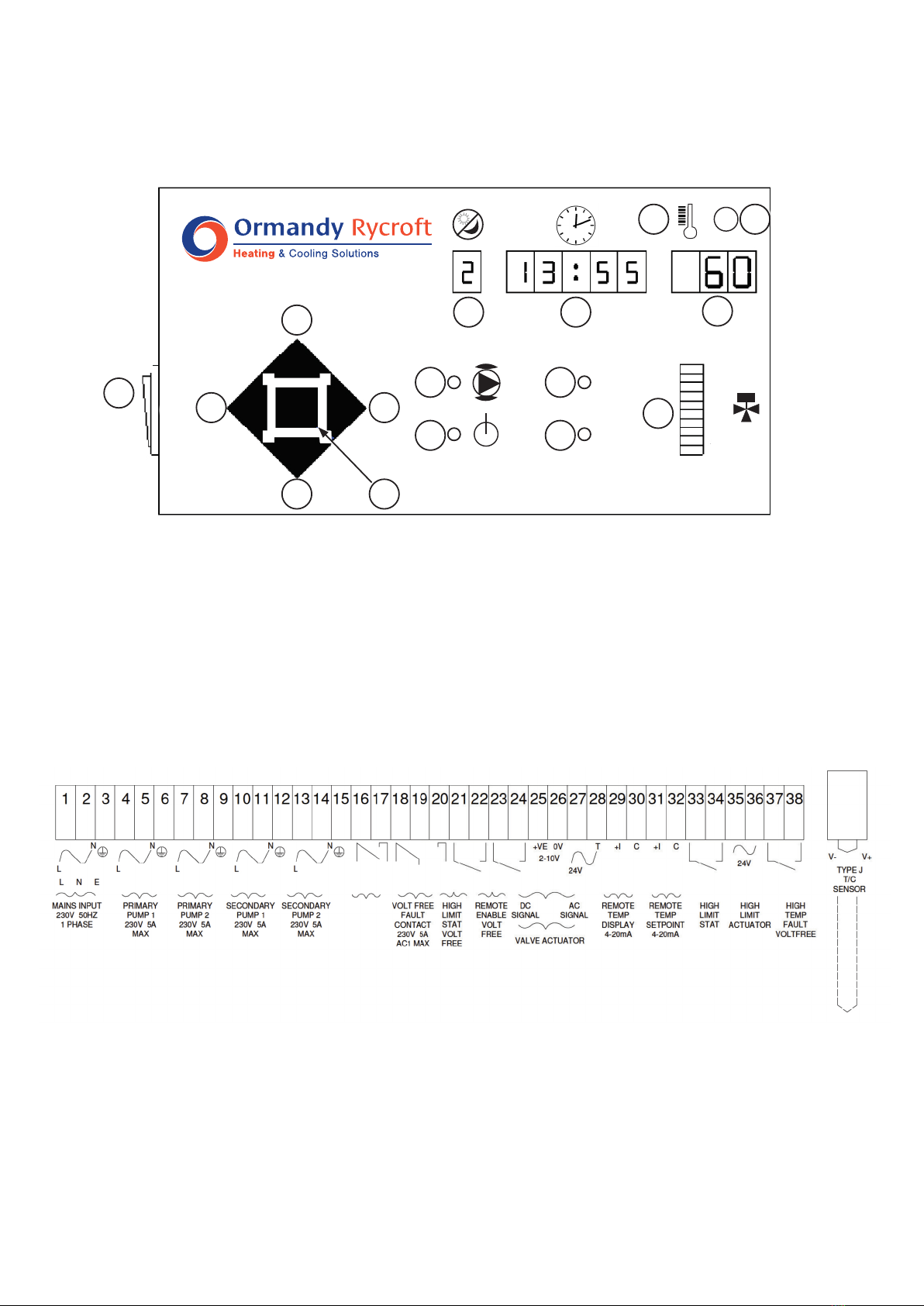

Thefrontpanelwillilluminate.Afterafewsecondsofselfchecks,thedisplayswillsettletotheDay (1)

(Time-clockonly),Time (2) and Temperature (3).Thepumpswillstart(11),thevalvewillopen(15)

and the system healthy indicator (13)willilluminate.

Thestandardtemperaturesettingis60°Candtheunitwillruncontinuously.(24houroperation).

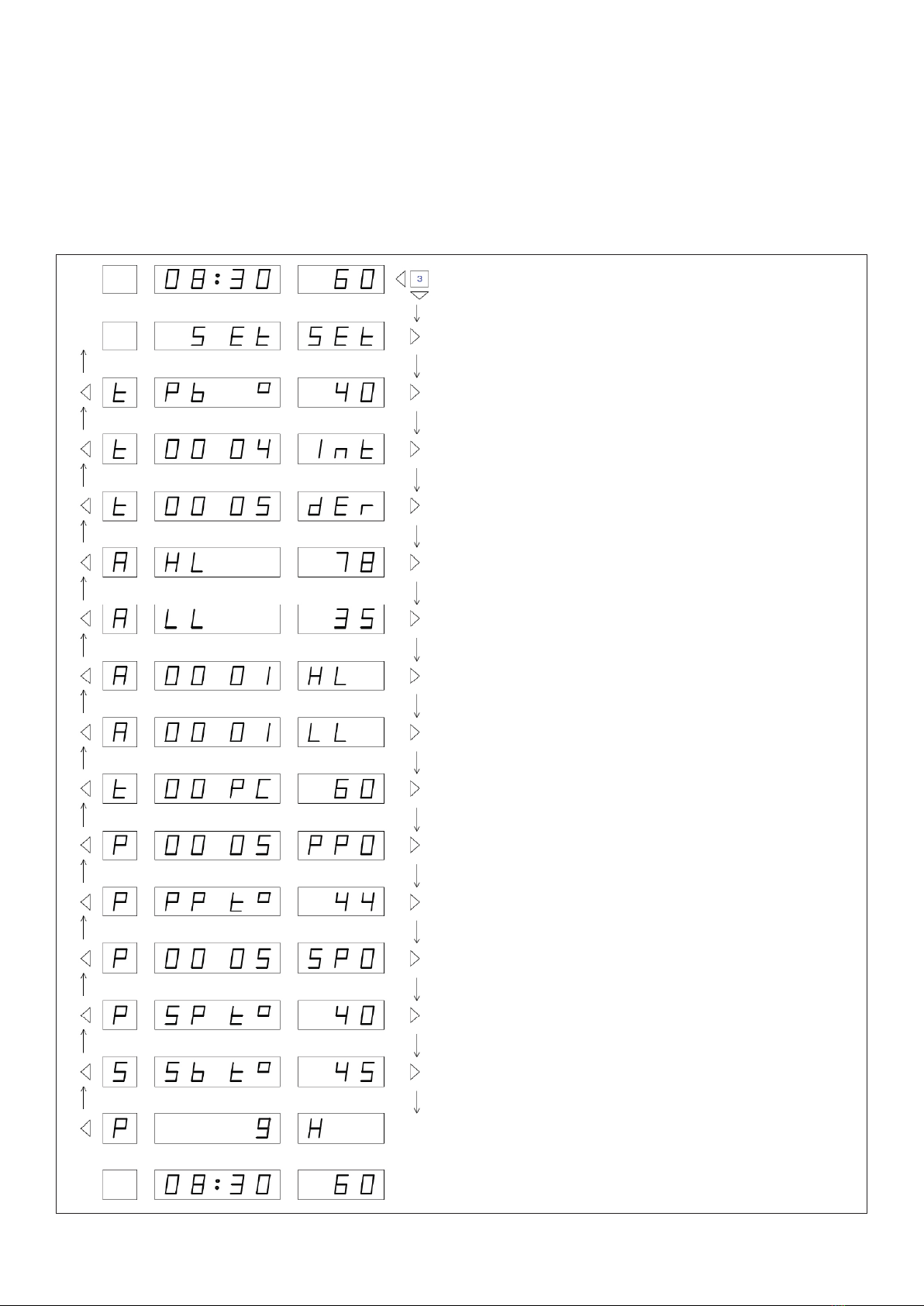

To change any of the default settings, refer to Figure 3

TheBreeze-Platecanbeenergisedbyitsowninternaltimeclockfunction,byaremoteswitchor

BuildingManagementSystemorbyacombinationofthetwo.