plug’n’dose AM

Operating and maintenance instructions

Copyright © Version 1.3 5 / 11

4Safety

4.1 Informal safety measures

» The operating and maintenance instructions should always be kept at the location

where the control system is in use.

» General and local regulations on health, safety and environmental protection must also

be provided and complied with.

4.2 Use of symbols

The following symbols are used in these instructions:

4.3 Correct use, warranty

The control system is designed for controlling our dispensers in non explosion-protected

environments.

Any

» modifications and additions,

» use of non-genuine spare parts,

» repairs by persons or organisations not authorised by the manufacturer

that are made without the express, written consent of the manufacturer will render the

warranty void and result in the loss of any right to make a claim under the warranty.

No liability can be accepted for damage caused by failure to observe the operating and

maintenance instructions.

4.4 Qualifications of the operators and maintenance personnel

The operating organisation is responsible for ensuring that the operators and

maintenance personnel are suitably qualified. The operating and maintenance

instructions must have been read and understood. The relevant technical rules and safety

regulations must be complied with.

Text in

italics

Names of keys/buttons, connectors, chapters, screen displays, proper

names and input boxes

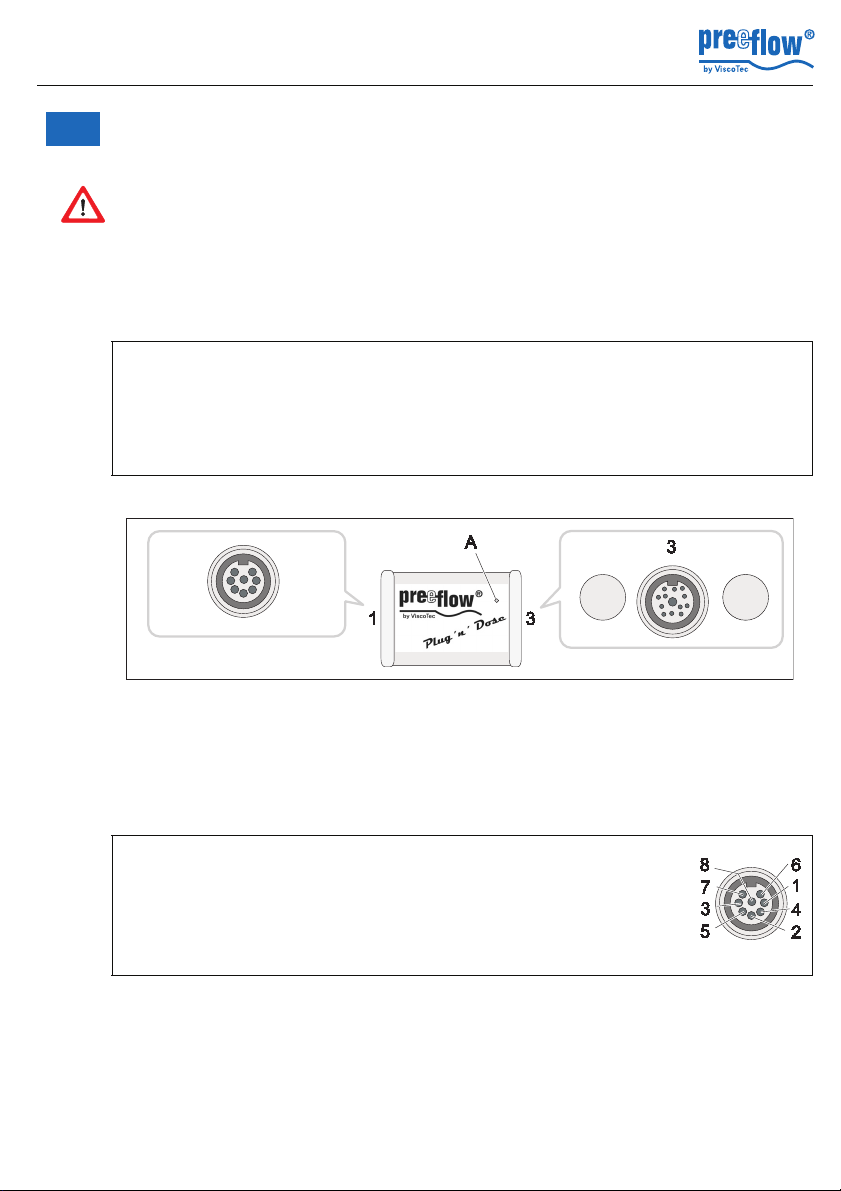

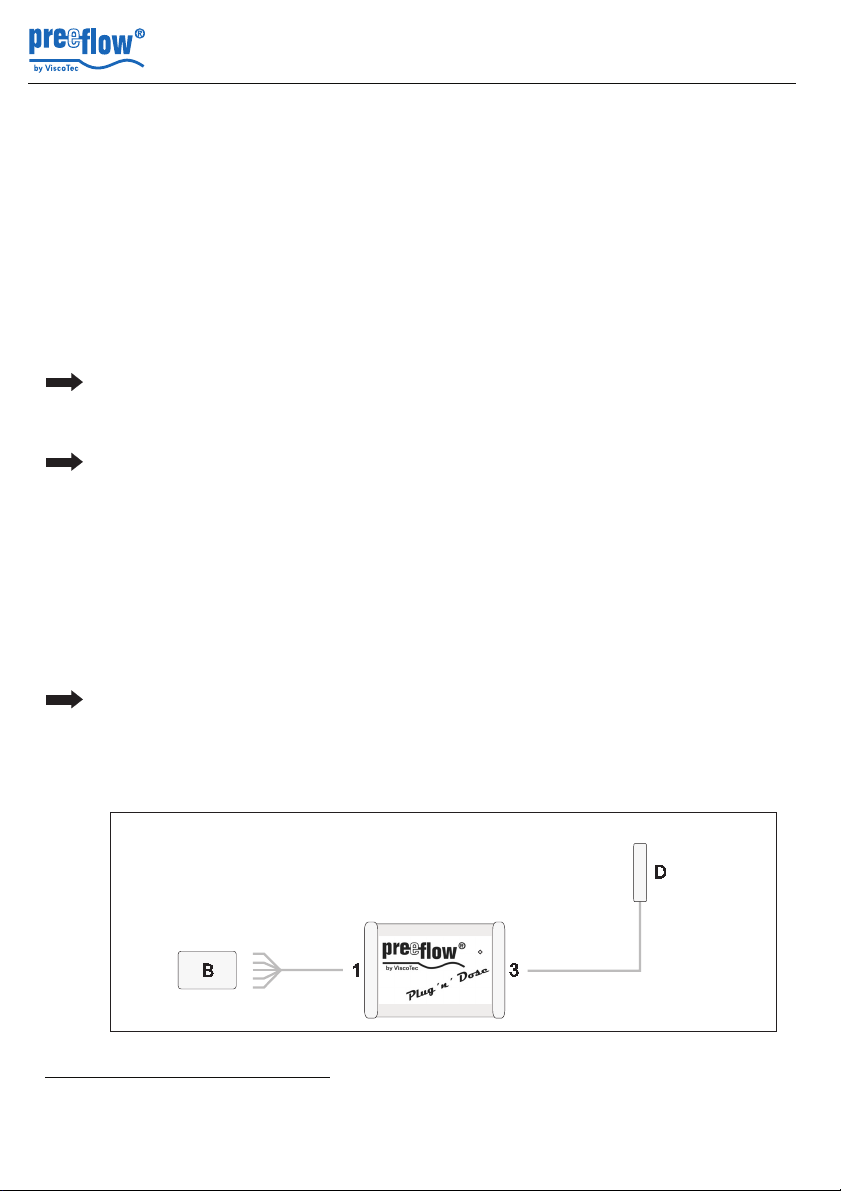

1 Legend number in an illustration

Warning note. Failure to observe these notes may result in injury and

damage to the control system.

Reference to technical information about operation and / or about

preventing damage.