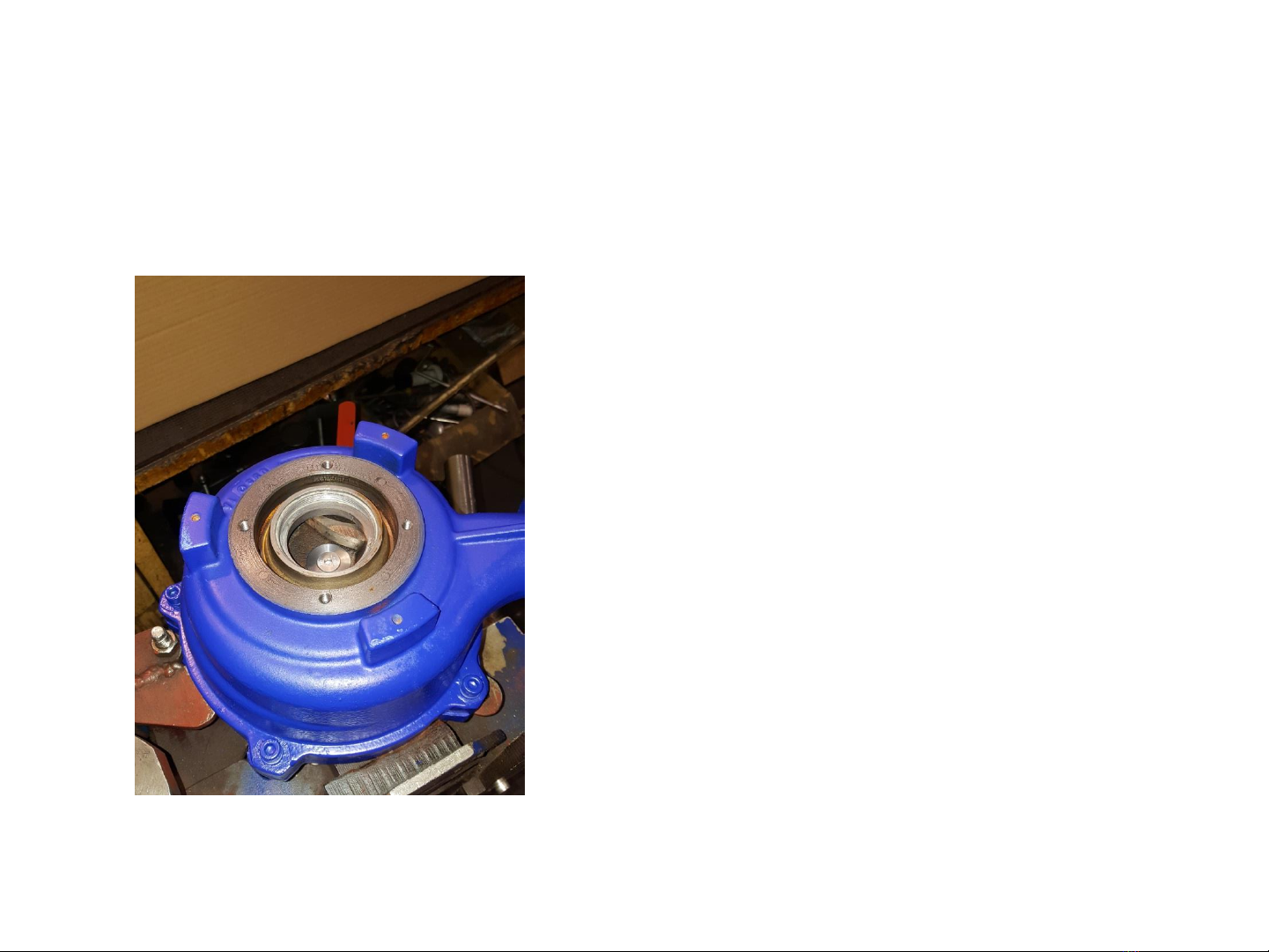

Disassembly of cutting system with

end-face seal at TES 148

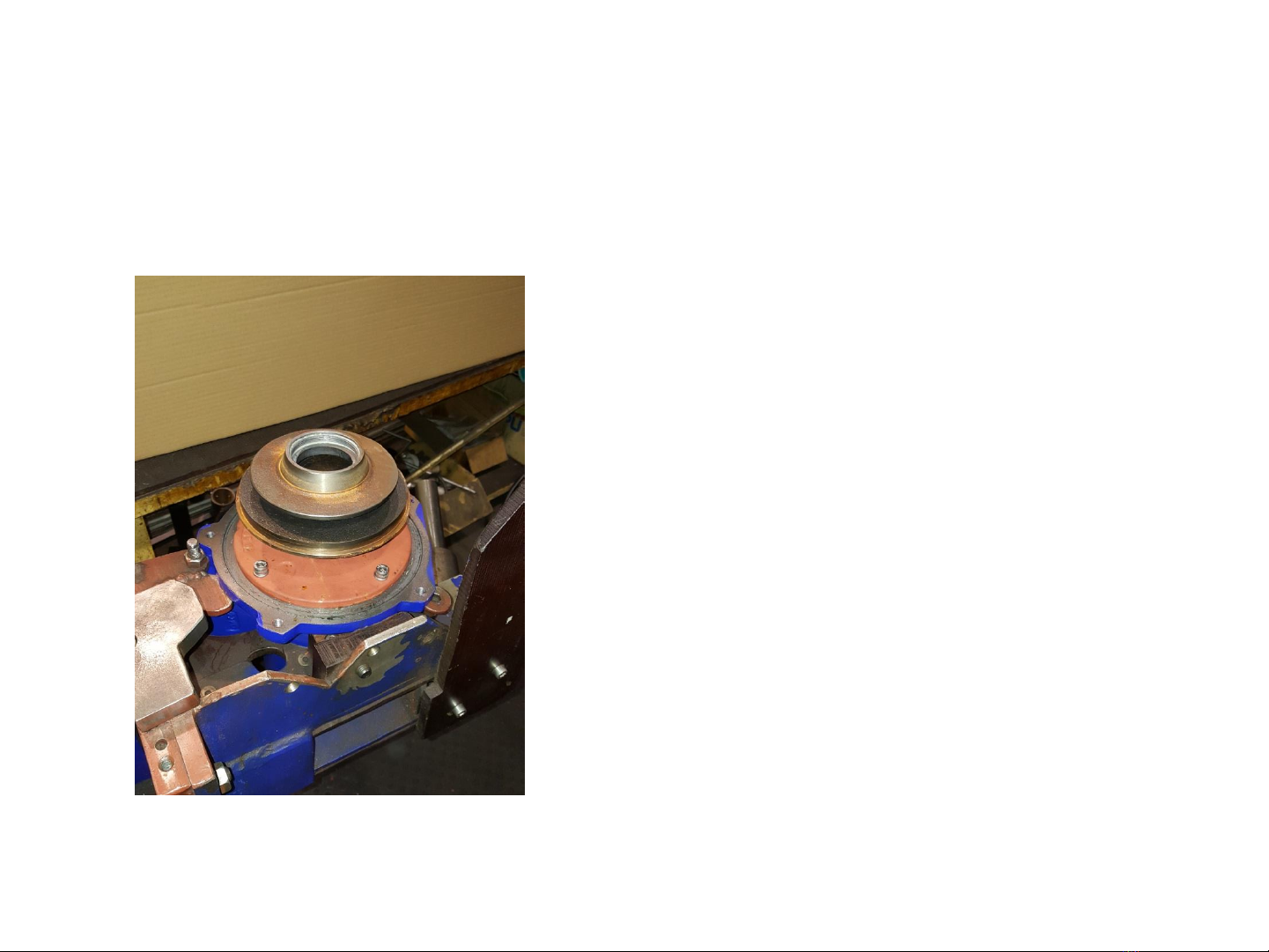

•Loose the cutter with an Allen key 8 mm

•If necessary, hit the cutter with a hammer

(wear protection goggles)

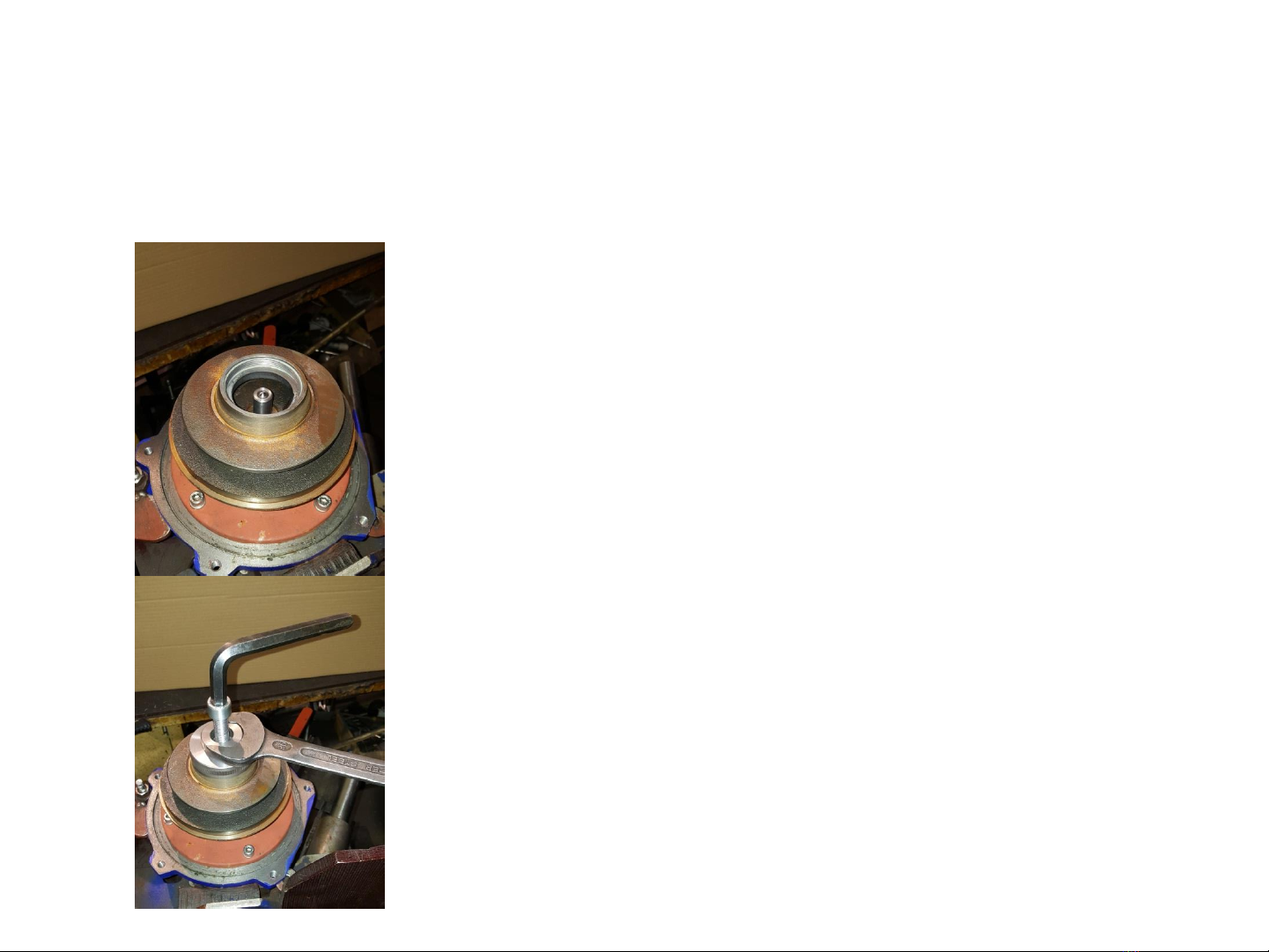

•if the cutter can not yet be loosened, smooth

separation can be caused by heating

•For this purpose heat the cutter evenly in the

area of the impeller

•After heating the cutter can be loosened

•Allow the cutter to cool down and disassemble

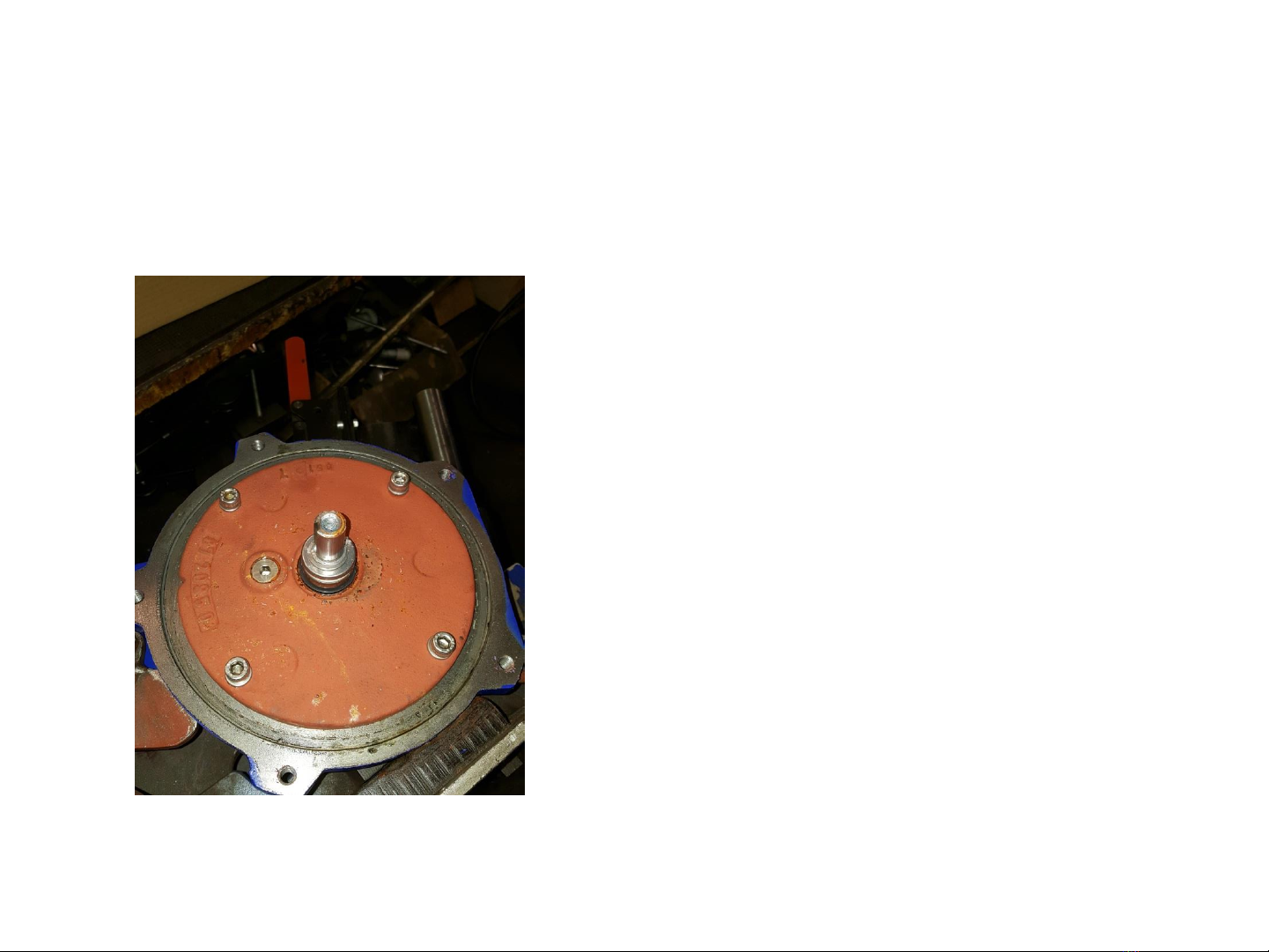

Note:

The more the cutting is worn out the more

complicated is the disassembly

5