I N S T R U C T I O N S

For the installation and maintenance variable area MDM

spring-assisted desuperheaters

IMI0046E.doc

Rev.0 14/03/13

20090 SEGRATE (MI)- via E.Fermi

TEL.(02) 269912.1 - FAX.(02) 2692.2452

Page 5 of 11

5. NOTICE ON SAFETY

Thorough checking and maintenance play a key role in ensuring the safe, reliable operation of all valves.

The service procedures recommended by CARRARO and described in this manual constitute effective

methods for performing the necessary maintenance operations. This service manual contains various

warnings and invitations to take care, which must be read carefully in order to minimise the risk of injury

to personnel and the possibility of adopting incorrect work methods which may damage the valves or

make their operation unsafe. It is also important to note that these warnings can never be exhaustive.

CARRARO is not in a position to know, assess and warn customers or users of all the conceivable

methods with which servicing may be carried out and all the potentially hazardous consequences of such

methods.

CARRARO has not therefore attempted to undertake such a task. Anyone using a service procedure or

tool not recommended by CARRARO must therefore make certain that neither their own safety nor that of

other people, nor the safety or correct operation of the valve is put at risk by the chosen work method.

If in doubt about a given procedure, contact CARRARO for advice.

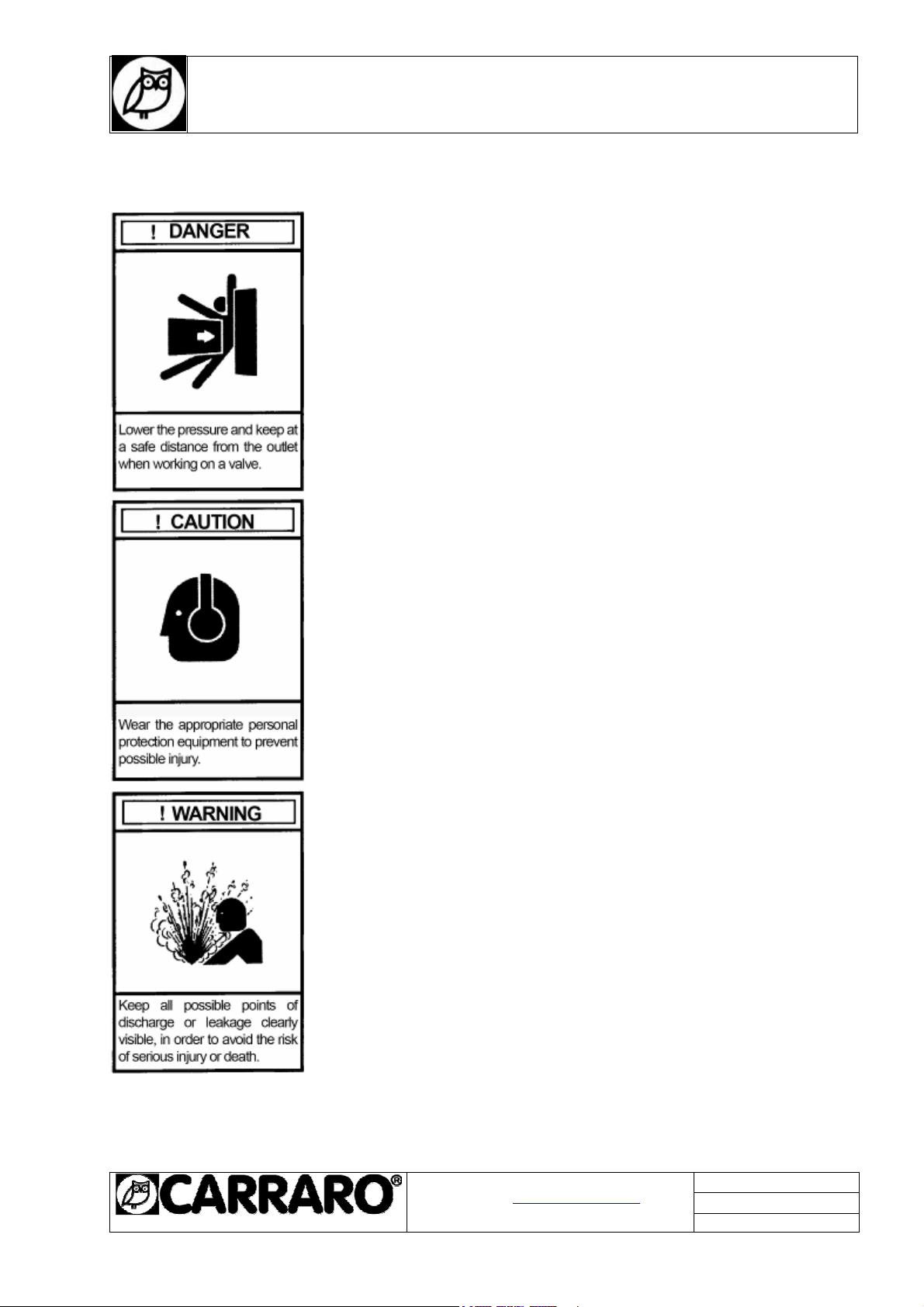

The testing, installation or disassembly of valves or accessories may lead to contact with fluid at high

pressures or temperatures and/or corrosive or erosive fluid, and fluid capable of generating a potentially

explosive atmosphere.

Comprehensive precautions must therefore be taken to prevent injury to personnel during testing,

installation or removal; including, by way of example only: ear defenders, protective goggles, protective

clothing such as gloves, etc., regardless of whether the persons in question are located directly in the

work zone or in the surrounding area.

In view of the widely varying conditions and circumstances that may arise in relation to the operations to

be carried out on products, and of the possible hazardous consequences of the way in which they are

conducted, CARRARO is not in a position to foresee everything that might pose a risk of injury to persons

or damage to property, and can therefore only offer, by way of assistance, this reminder to take care and

a few suggestions (set out below) on safety precautions.

It is the responsibility of the user of CARRARO products to attend to the training of the personnel

assigned to their use.

It is imperative that such personnel acquire a full knowledge of the instructions relating to the product and

of this manual.